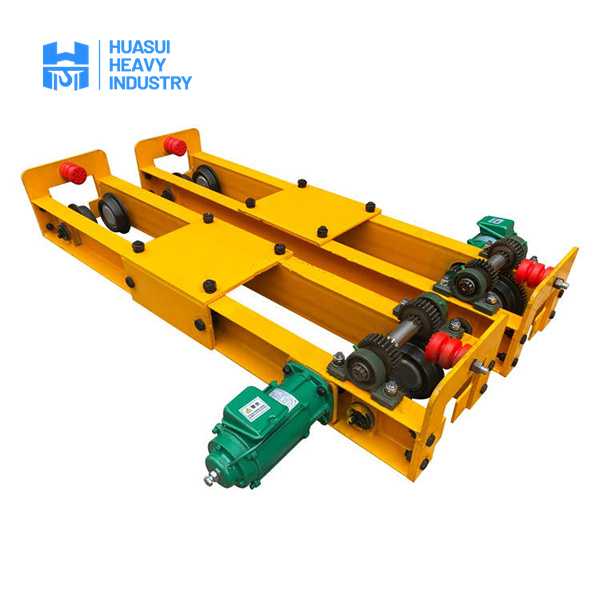

Crane End Carriage

Features

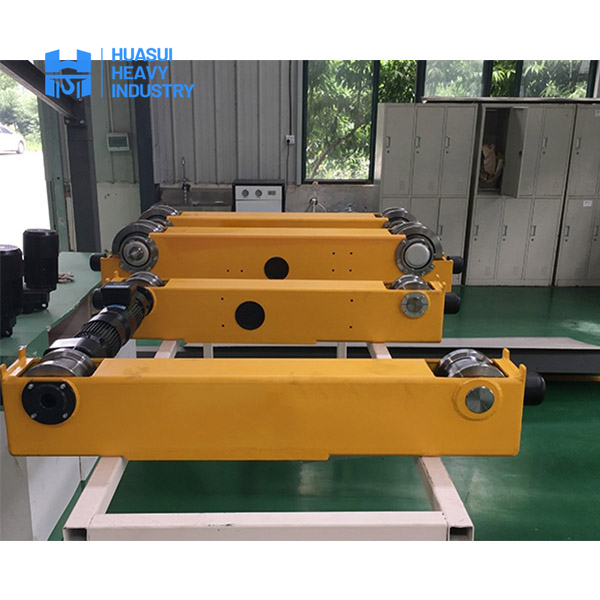

- The steel structure is a torsion resistant box girder prepared to be connected to the crane girder.

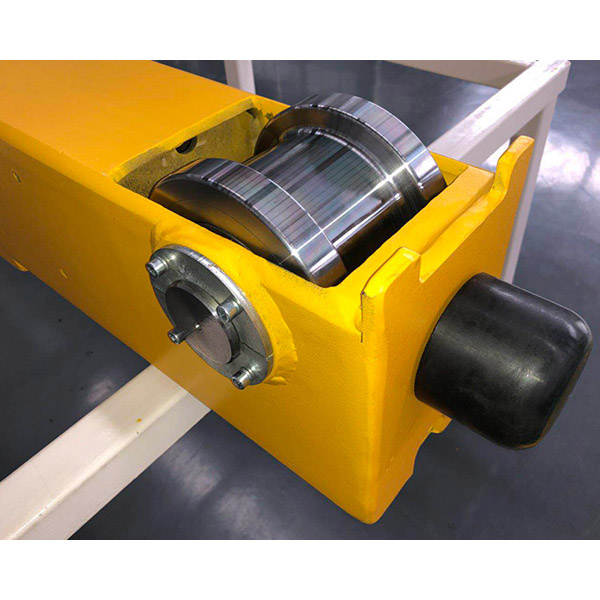

- Rigid special end carriage-girder connections and forged wheel design ensure years of low maintenance operation.

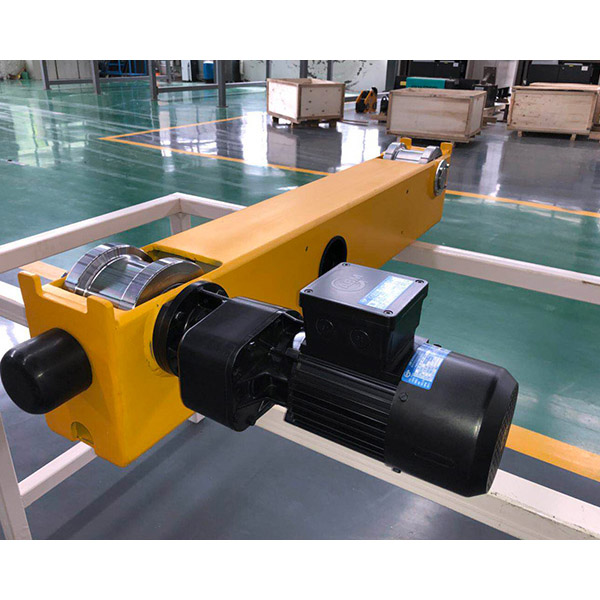

- Quick disconnection electrical plugs and a power lock wheel assembly providing a easy inspection and service.

- High grade rubber bumpers are bolted on for energy absorbing, allowing easy removal for replacement or maintenance.

- Three stage motor-gearboxes, travel wheels with double flanged with mounted bearings, drive to the wheels is direct via splined shaft.

Advantages

- Light-weight of end carriage

- Modular design,flexible assembly

- Spheroidal graphite cast or forged steel wheels

- Wide range of diameter

- Variable frequency drive, smooth running

Technical Parameters

| Parameter | ECLM (1–10 Ton) | ECLM (10–50 Ton) | ECLM (50–150 Ton) |

| Rated Load Capacity (t) | 1 – 10 | 10 – 50 | 50 – 150 |

| End Beam Length (m) | 4 – 8 | 8 – 16 | 16 – 24 |

| Material | Q235 / Q345 Steel | Q345 Steel | Q345 / High-Strength Steel |

| Section Dimensions (mm) | 150 x 75 x 8 | 200 x 100 x 10 | 300 x 150 x 14 |

| Weight (kg/m) | ~150 | ~350 | ~550 |

| Finishing | Galvanized / Powder Coated | Galvanized / Powder Coated | Galvanized / Powder Coated |

| Design Standard | EN 15011 / ISO 9001 | EN 15011 / ISO 9001 | EN 15011 / ISO 9001 |

| Applications | Small overhead cranes, mini gantry cranes, light-duty applications | Standard overhead & gantry cranes in industrial settings | Heavy-duty overhead & gantry cranes, 150-ton class lifting systems |

Note: The above parameters are indicative and can be customized to meet specific design and operational requirements.

Combination Form Of End carriage with Wheel