Project Background

On September 11, 2025, HSCRANE completed production and shipment of 3-ton FEM standard single girder overhead crane end carriages. The equipment is destined for a Mexican factory to support a new material-handling system. This shipment marks the start of the project’s delivery phase and another step in HSCRANE’s Central American expansion.

Mexico’s manufacturing sector has grown rapidly, especially in automotive, machining, and steel structure industries. These sectors demand efficient, safe, and internationally compliant lifting equipment. The client, a mechanical parts manufacturer, needed a stable and low-maintenance crane system for 3-ton loads. After evaluating multiple global suppliers, the customer chose HSCRANE as its strategic partner. HSCRANE’s strengths in lightweight FEM standard single girder overhead crane design and global service network ensured full-scope support. We provided a complete solution covering design, manufacturing, and shipment logistics.

Product Technology and Specifications

The end carriages are key components of the FEM standard single girder overhead crane structure. They adopt a modular, lightweight, and high-rigidity design for frequent and precise operation.

Main specifications are as follows:

- Rated load: 3 tons

- Span: 22. 5 meters

- Type: FEM standard single girder overhead crane

- Rail type: 50×50 mm square steel rail

- Travel motor power: 0. 55 kW × 2

- Power supply: 440 V, 60 Hz, three-phase

The main frame is built from high-strength low-carbon steel via CNC cutting and automatic welding. All welds undergo ultrasonic inspection to ensure structural integrity. The travel system uses a variable-frequency drive for smooth start, precise positioning, and longer service life.

To resist Mexico’s coastal heat and humidity, the surface uses a three-layer coating system. It includes sandblasting, epoxy primer, and polyurethane topcoat for corrosion and aging resistance.

International Logistics and Delivery

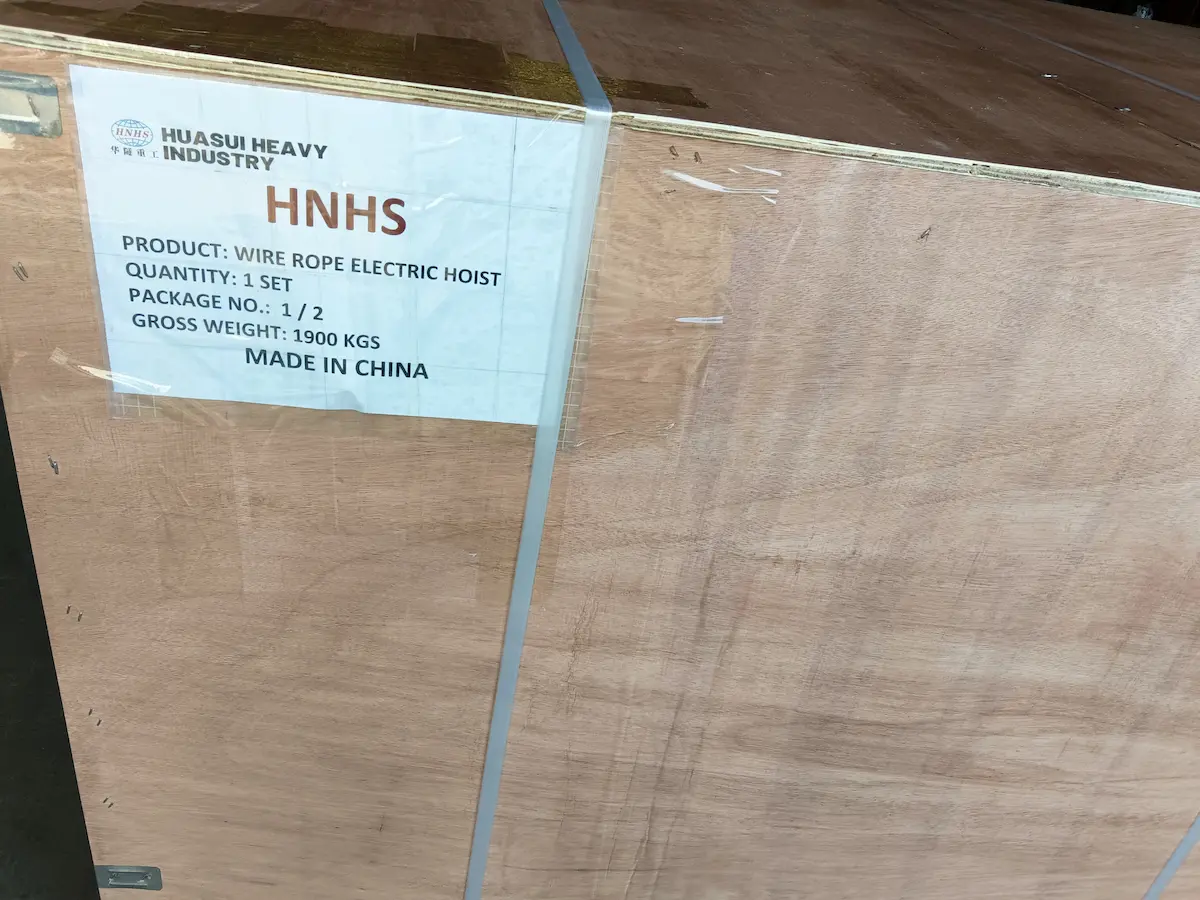

The end carriages were shipped by sea from a Chinese port to Mexico. HSCRANE’s logistics team handled packaging, container reinforcement, and export clearance. All parts were packed to meet international standards for moisture, vibration, and corrosion protection. This ensures the equipment remains intact during the multi-week ocean voyage. We provided detailed installation drawings, technical manuals, and remote guidance. On-site commissioning and online support are also available upon customer request.

Client Feedback and Project Value

After installation, the customer praised HSCRANE’s product quality and technical service. The end carriages operate smoothly, with low noise and precise coordination with the girder and hoist. This significantly improved lifting efficiency and operational safety. The project modernized the customer’s production process and supported future expansion plans. The client plans to continue purchasing HSCRANE FEM standard single girder overhead cranes to sustain business growth.

This successful delivery again proves HSCRANE’s technical expertise and global delivery capability. HSCRANE will continue promoting high quality, intelligent, and global development concepts. We aim to deliver safer, more efficient, and energy-saving lifting solutions worldwide. Our mission is to support sustainable growth and efficiency upgrades in global manufacturing.