Introduction

The crane hook is the core component connecting loads with crane wire ropes or chains. It directly bears the force transmission between materials and equipment. Moreover, the safety and reliability of hooks play a decisive role in lifting operations. Any damage or failure can cause severe equipment accidents and human hazards. Therefore, during crane operations, hook quality must be ensured with sufficient strength and toughness. Hooks must also undergo strict inspection and maintenance. Only by guaranteeing hook quality and safety can overall crane efficiency and workplace safety be secured.

Basic Function of Crane Hooks

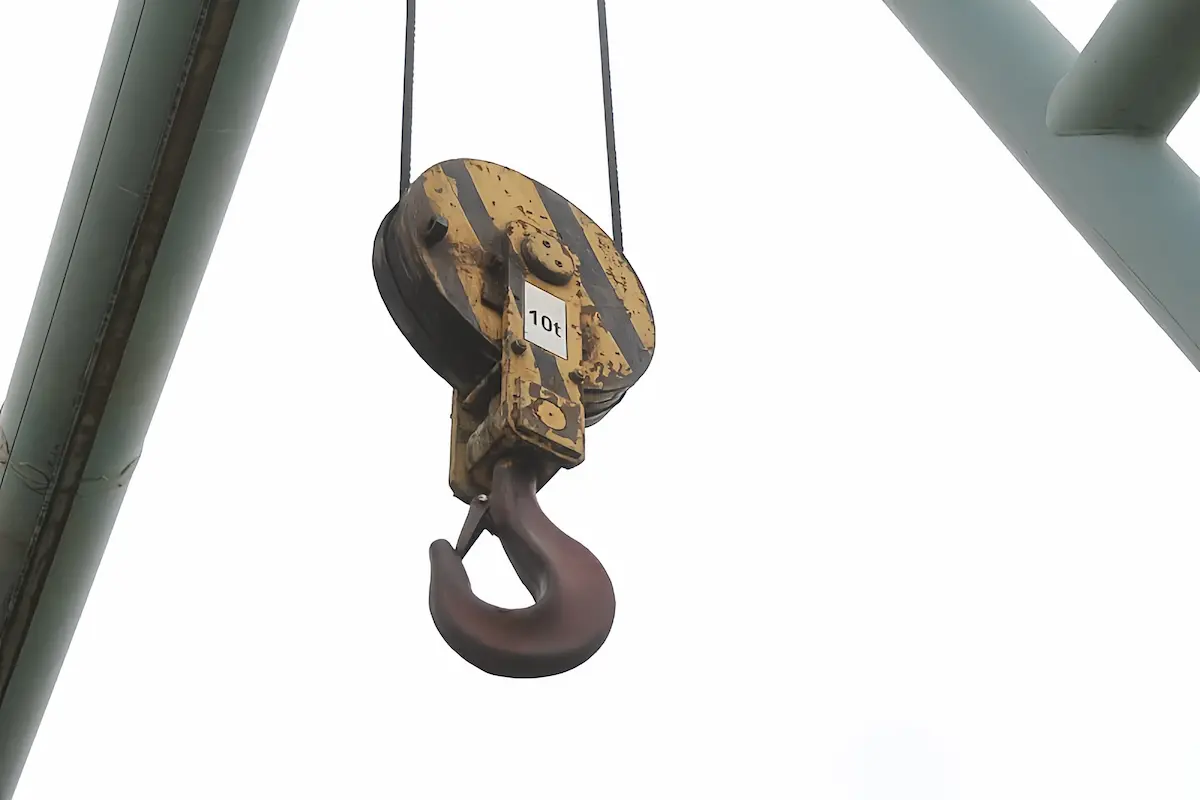

The primary function of crane hooks is serving as the key connection point for lifting loads. They directly bear and transmit weight, making them indispensable in lifting operations. Hooks must meet high-strength and high-reliability load-bearing requirements while ensuring operational safety. During use, hooks work closely with wire ropes, lifting gear, and pulley blocks, forming a complete hoisting system for smooth and efficient material handling.

Common Types of Crane Hooks

In different lifting scenarios,hook structures and materials vary based on load capacity, environment, and operational needs. The main types of crane hooks include:

Single Hook

The single hook is the most common type, featuring a simple structure and easy operation. It is mainly suitable for light or medium-duty lifting, such as with single-girder overhead cranes or electric hoists. With its compact structure and light weight, the single hook is widely used in small factories, warehouses, and maintenance operations.

Double Hook

The double hook is typically used for heavy-duty lifting, with two ends distributing the load to reduce stress concentration risks. It is commonly applied in large bridge cranes and gantry cranes, widely serving industries such as steel, mining, and shipbuilding that require large-scale heavy load handling.

Forged Hooks

Forged hooks are made from high-strength alloy steel through integral forging, featuring dense structure, excellent impact resistance, and superior fatigue performance. They are ideal for heavy-duty and high-frequency operations, such as in metallurgical cranes, mining equipment, and heavy port machinery. The forging process ensures safety and stability of the hook even under extreme working conditions.

Special Hooks

Stainless Steel Hooks: These provide excellent corrosion resistance, suitable for marine engineering, chemical industries, and high-humidity or corrosive environments.

Customized Hooks: These are designed for specific industry needs, such as large roll lifting in the paper industry or high-temperature heavy-duty handling in the steel sector. Such hooks often combine special materials and structures to ensure efficiency and safety in demanding operations.

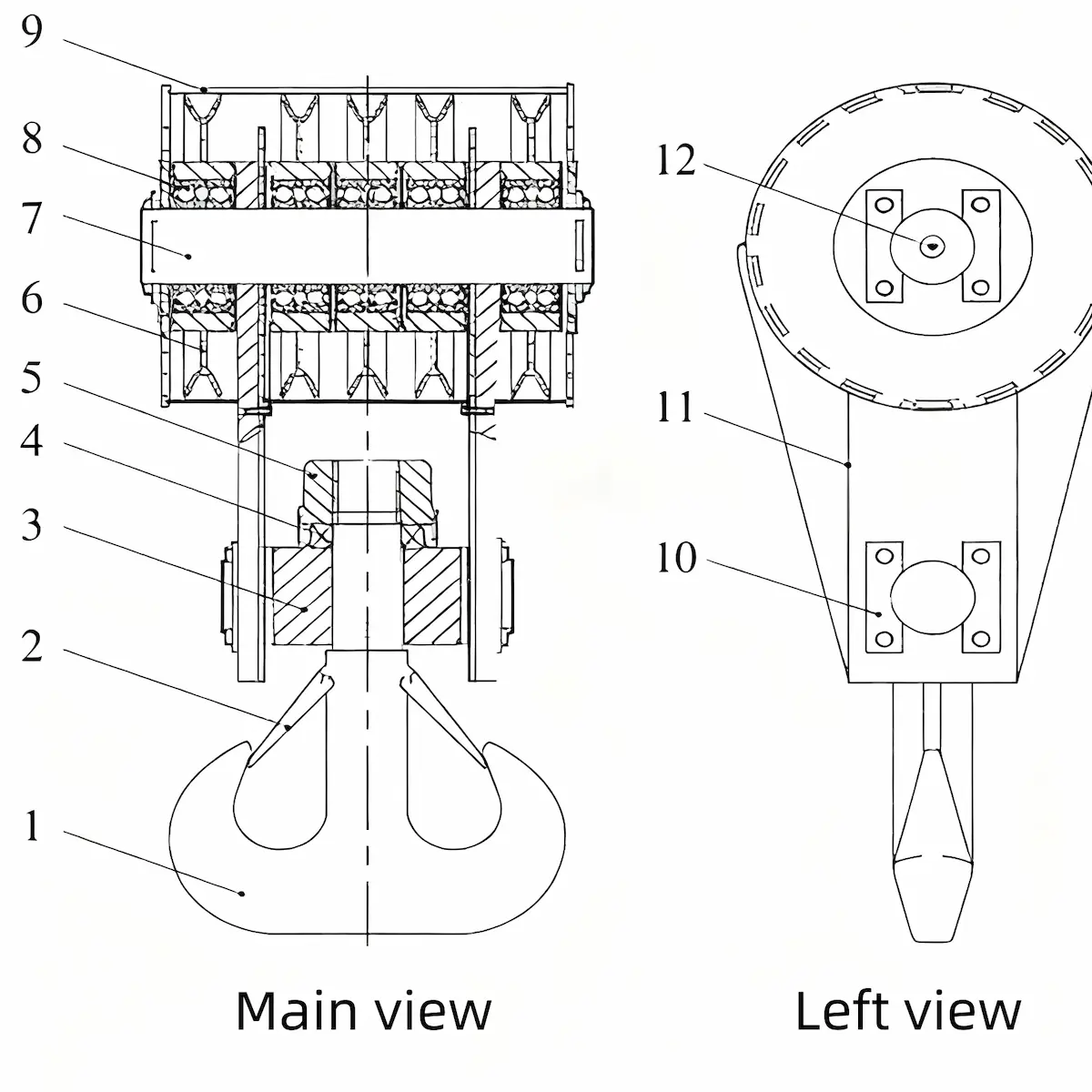

Key Parts of Common Crane Hooks

Taking a 75-ton double hook as an example:

(1) Straight-shank double hook

(2) Safety latch plate

(3) Hook crossbeam

(4) Thrust self-aligning roller bearing

(5) Hook nut

(6) Pulley

(7) Pulley shaft

(8) Deep groove ball bearing

(9) Pulley cover

(10) Shaft end baffle

(11) Pull plate

(12) Oil cup

Crane hook production process

The crane hook production process includes Blanking, Heating, Primary forging, Second-Bending, Die-forging, Normalizing, Sandblasting, Machining, Painting and Assembly, each step affecting crane safety and service life.

Crane Hook Selection Guide: How to Choose the Right Hook

|

Selection Dimension |

Classification |

Recommended Hook Type |

Application Scenario |

| By Load Capacity | Light load (≤10 tons) | Single hook, simple structure, light weight | Light-duty cranes, electric hoists, single-girder bridge cranes for small loads and low-frequency operations |

| Medium load (10–75 tons) | Single or double hook, double hook distributes load and increases safety | Medium and large bridge or gantry cranes, balancing capacity and flexibility | |

| Heavy load (≥75 tons) | Double hook or special custom lifting gear with uniform stress and high capacity | Large bridge cranes, port gantry cranes for heavy lifting to avoid stress concentration | |

| By Crane Type | Bridge crane | Single or double hook | Workshops, warehouses, indoor operations with relatively uniform load distribution |

| Gantry crane | Double hook or special lifting gear to meet dispersed load and large span | Ports, yards, heavy cargo handling such as containers and steel materials | |

| Jib crane | Single hook, light and flexible operation | Fixed-point operations in workshops with small load and limited radius | |

| Special crane | Customized alloy hook with special heat resistance treatment | Metallurgy, shipbuilding, nuclear power and other special scenarios | |

| By Working Environment | High-temperature environment | High-temperature alloy hook with special heat treatment to maintain strength | Suitable for 200°C to 800°C operations, preventing material softening failure |

| Corrosive environment | Stainless steel hook or hooks with nickel plating, thermal zinc spraying, or anti-corrosion coating | Resists salt spray, acid and alkali corrosion, extending service life in harsh environments | |

| Harsh working conditions | Forged hook with fatigue resistance and higher impact performance than welded structures | Mining, construction and high-frequency heavy-load operations with collision or frequent lifting | |

| By Operation Frequency & Service Life | Low-frequency use | Economical hook meeting basic safety standards | Equipment maintenance, warehouse replenishment, low-frequency low-load scenarios focusing on cost control |

| Medium-frequency use | Standardized hook meeting ISO/FEM/GB standards to ensure safety factor | Factory production lines, routine material handling balancing safety and economy | |

| High-frequency use (long service life) | High-strength forged double hook with safety latch and automatic lock, redundancy if needed | 24-hour port loading, continuous metallurgical production ensuring long-term fatigue life and safety |

Crane Hook Safety Standards and Inspection

As the core load-bearing component of a crane, the hook’s safety directly determines overall lifting efficiency. The following explains four aspects: international standards, common failure modes, periodic inspection and scrapping criteria, and operator safety precautions.

International Standards (ISO, DIN, FEM, GB/T)

Different countries and organizations set safety standards for crane hooks, varying in technical requirements, test methods, and material specifications, but all aim to ensure load safety.

|

Standard System |

Standard Number |

Scope of Application |

|

ISO |

Applies to all types of crane hooks including forged and laminated hooks | |

|

DIN |

Mainly for European market crane hooks with focus on safety factors and use scenarios | |

|

FEM |

For hooks used with cranes emphasizing compatibility and dynamic load adaptability | |

|

GB/T |

Chinese recommended and mandatory standards for crane hooks |

Common Failure Modes and Causes of Crane Hooks

Crane hook failure is a major cause of lifting accidents. Failure modes are closely related to environment, maintenance, and material defects. Main failure modes include:

- Cracks: Stress concentration from material fatigue or impact, especially at the neck, eye, welds, or repair zones. Cracks are critical precursors to failure and require non-destructive testing (NDT).

- Plastic deformation: Overload, lateral forces, or impact cause hook opening enlargement, neck bending, or excessive rotation, reducing load capacity and safety index.

- Wear: Long-term friction with slings or pulleys reduces dangerous cross-section dimensions, causing wear, pits, or indentations that directly affect maximum load capacity.

- Corrosion: Chemical or electrochemical action causes surface loss, reducing effective cross section and creating stress points, especially dangerous at shank diameter and hook eye.

- Fatigue damage: Repeated cyclic loading causes micro-crack growth or surface plastic deformation, which can accumulate and result in sudden fracture.

Crane Hook Periodic Inspection and Scrapping Criteria

- Periodic Inspection

According to standards, crane hook safety inspections are divided into three levels:

|

Inspection Level |

Inspection Interval |

Inspection Items |

Inspection Methods |

|

Daily Inspection |

Before each operation (≤24h) | 1. Check for visible cracks, deformation, or corrosion2. Verify anti-detachment devices are intact (no breakage or jamming)3. Check if connecting pins are loose or missing4. Ensure markings are clear (rated load, validity) | Visual inspection, tactile check (feel for cracks or protrusions) |

|

Monthly Inspection |

Every month, focus on hook usage frequency | 1. Dimensional measurement: throat opening, hook neck diameter, twist or deformation2. Non-destructive testing: 100% magnetic particle or penetrant testing on critical sections3. Load test: For hooks suspected of defects, perform static load test at 1.1× rated load (hold 5 min, check deformation) | Caliper/micrometer for dimensionsMT/PT for crack detectionTensile testing machine for load test |

|

Annual Inspection |

Once a year (mandatory for all hooks) | 1. Comprehensive review of monthly inspection items2. Material property sampling (e.g., hardness test to detect substandard material)3. Trace usage records and evaluate service life | HB or BRC testingReview equipment recordsService life calculation (based on usage frequency) |

- Mandatory Scrapping Criteria

Stop using and scrap the hook immediately under any of the following conditions. Repair and reuse are strictly prohibited:

|

Failure Type |

Scrapping Criteria |

|

Cracks |

Any visible crack (by eye or MT/PT), regardless of size, scrap immediately |

|

Opening deformation |

Opening increased by 10% from original size |

|

Twist deformation |

Hook twist angle ≥10° (measured with protractor from vertical axis) |

|

Neck wear |

Neck diameter wear exceeds 10% of original diameter |

|

Material degradation |

Hardness test out of standard range or significant impact toughness reduction |

|

Other defects |

Damaged safety latch irreparable, pinhole wear exceeds 5% of original, unclear or missing hook markings preventing rated load traceability |

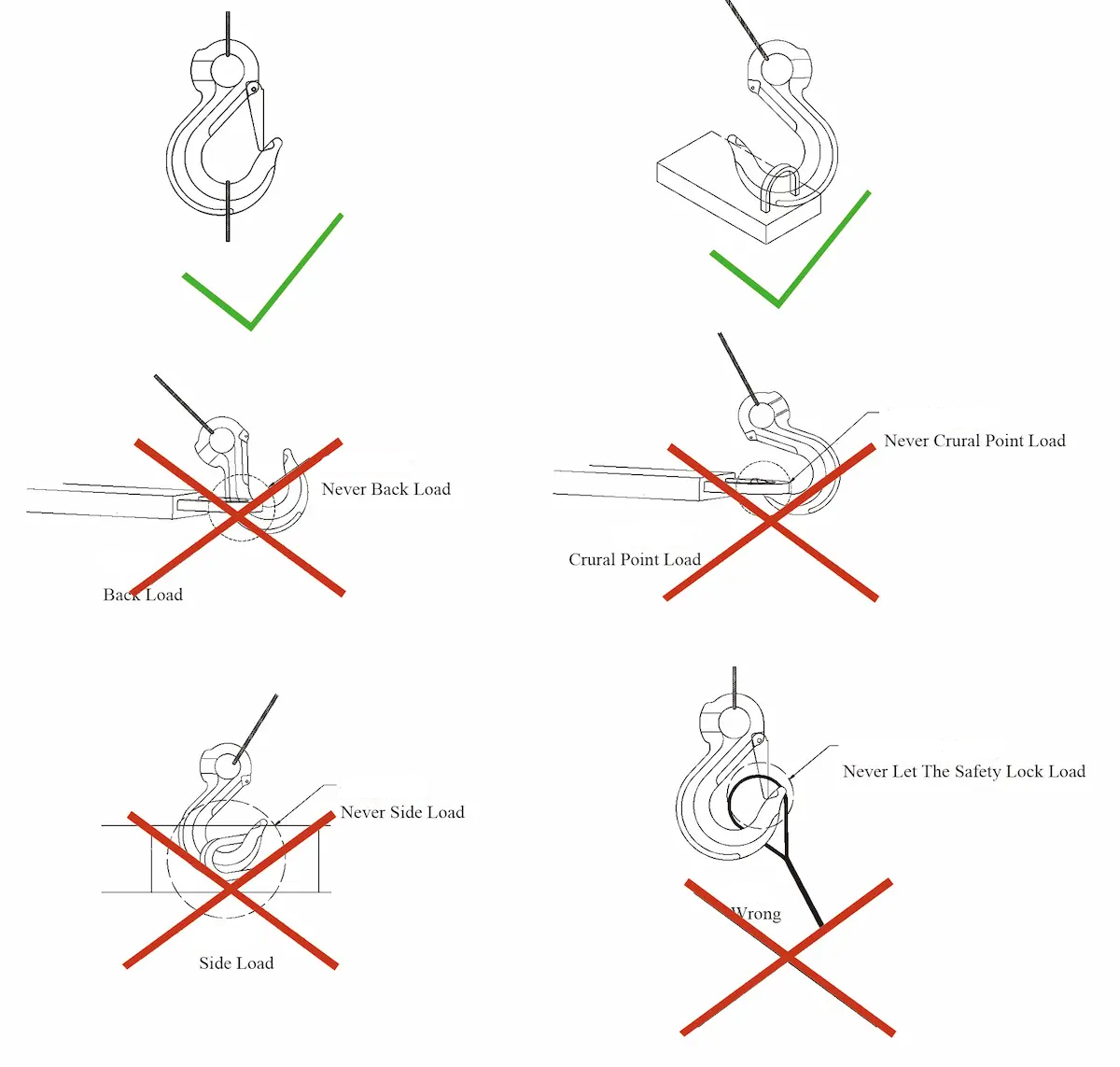

Operator Safety Precautions

Safe use of crane hooks depends on both equipment quality and operator discipline:

Pre-operation check

Visual: Inspect for cracks, rust, or deformation, and ensure safety latch integrity

Marking: Confirm rated load matches operation load, strictly forbid overloading

Connection: Check hook, beam, and pulley pins are tightened, cotter pins complete and unbroken

During operation

Vertical lifting: Ensure sling and hook bear load vertically to avoid side forces or skew

Smooth operation: Lift, lower, and slew smoothly, avoid sudden stops or swings to prevent impact loads

No side pulling:Side pulling causes lateral forces, twist deformation, or sling slippage, a major hidden danger

Avoid friction: Ensure sling sits fully in hook bottom with even force, prevent hard rubbing on hook edges

Post-operation maintenance and records

Clean and maintain:Remove dust, oil, or rust, lubricate pin connections to prevent wear

Report abnormalities:Stop using hook immediately if cracks, deformation, or excess wear are found, attach “Do Not Use” tag, and report to maintenance

Record keeping: Complete hook usage records and archive inspection reports for at least the hook’s service life

Common Incorrect Hook Operation Illustrations

Why Choose HSCRANE Parts Hooks

Choosing HSCRANE Parts hooks means choosing safety and reliability. We use premium forging technology and strictly follow international standards to ensure high strength and durability. Our products cover single hooks, double hooks, laminated hooks, and various other models, with full customization options to meet different industries and working conditions. HSCRANE offers a complete global shipping system and professional after-sales service, providing customers with worry-free support.

Contact us now to get the best hook solution and quotation for your project.

Frequently Asked Questions

Q1: How often should crane hooks be inspected?

A1: Follow ISO standards. Daily visual checks before use, detailed monthly inspections, and at least one full annual inspection.

Q2: Can a hook with slight deformation or cracks continue to be used?

A2: No. Any cracks, obvious wear, or hook opening exceeding 10% must be scrapped and replaced immediately.

Q3: What types of hooks does HSCRANE provide?

A3: We supply single hooks, double hooks, laminated hooks, and various models, with custom services for different industries and conditions.

Q4: How to choose the right crane hook?

A4: Consider load capacity, crane type (bridge, gantry, jib, etc.), working environment (high temperature, anti-corrosion, heavy load), operation frequency, and service life.

Q5: Does HSCRANE provide international shipping and after-sales support?

A5: Yes. We support global delivery, installation guidance, spare parts supply, and after-sales services to ensure worry-free use.

Q6: Can the hook safety latch (lock tab) be removed or bent open?

A6: Absolutely not. The safety latch prevents slings or lifting straps from accidentally slipping out. Any removal, bending, or wire substitution is extremely dangerous and increases detachment risk.

Q7: Why does my hook rotate stiffly?

A7:

- Lack of lubrication: Bearings or bushings are dry. Lubricate regularly as per the maintenance manual.

- Bearing/bushing damage: Rolling elements or cages are damaged and must be replaced by professionals.

- Foreign matter intrusion: Dust or debris entered the rotating part and needs cleaning.