Abstract

This article analyzes common crane safety protection devices including height limit switches and travel limit switches. It explains their working principles, control targets, and main functions. It highlights their roles in preventing hook overhoisting, overtravel operation, and crane collision accidents. By comparing differences in acting direction, risk prevention focus, and installation and maintenance, the article clarifies the core distinctions between height limits and travel limits. It also provides practical configuration recommendations based on real operating conditions. In addition, it introduces HSCRANE advantages in crane safety protection systems. This helps improve the safety and operational stability of overhead crane operation.

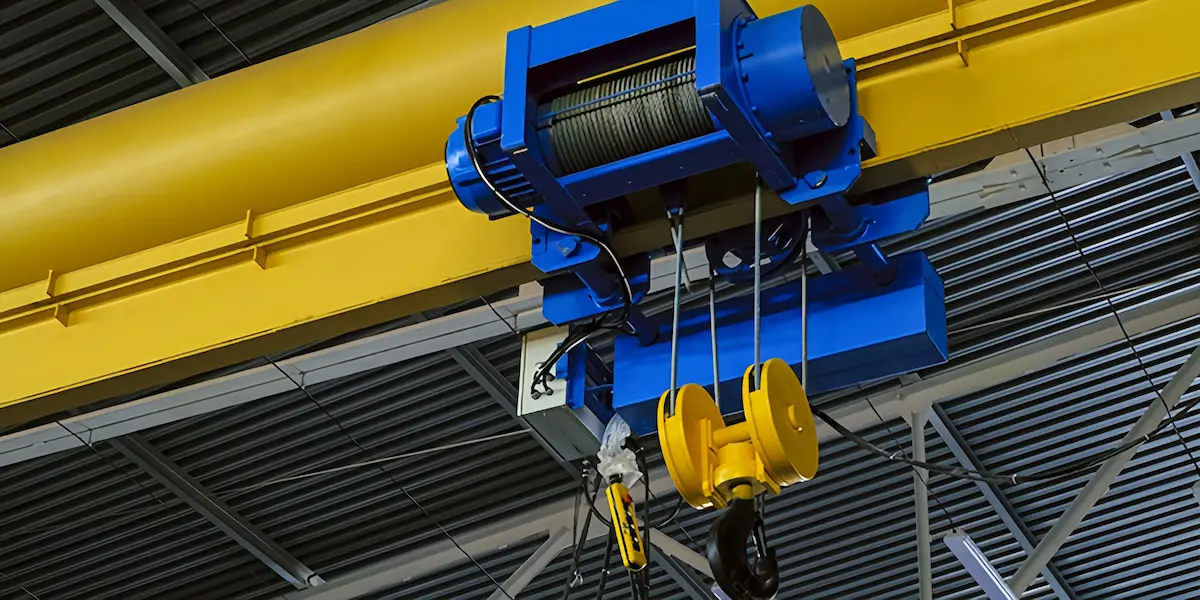

During crane operation, safety control is the primary concern. Many crane accidents show that mechanical loss of control and electrical failures are main risk sources. Typical risks include hook overhoisting, equipment collision, and overtravel operation. As critical crane safety protection devices, limit switches cut off power before reaching extreme positions. They effectively prevent misoperation and equipment damage. They play an irreplaceable role in protecting personnel safety and extending equipment service life.

What Is a Crane Hoisting Height Limit Switch

Among various crane safety protection devices, the hoisting height limit switch is one of the core components ensuring safe lifting operation. It directly affects the service life and operational safety of the hook, wire rope, drum, and the entire hoisting system. It is a critical line of defense against serious mechanical accidents.

Definition and Basic Functions of the Hoisting Height Limit

A crane hoisting height limit switch is a safety protection device used to restrict the maximum vertical lifting height of the hook or lifting attachment.

When the hook rises to the preset maximum height, the height limit switch activates automatically. It cuts off the hoisting power supply or sends a control signal. This forces the hoisting mechanism to stop immediately. It prevents hook overhoisting accidents. For example:

●Exceeding the safe lifting height may damage wire ropes, pulley blocks, and hoisting mechanisms.

●Hook overhoisting may cause load loss of control and falling hazards.

●Such accidents increase failure rates and maintenance costs, affecting normal crane operation.

Its core functions include:

●Preventing the hook from exceeding the safe lifting height.

●Protecting wire ropes, drums, and hoisting mechanisms.

●Reducing safety risks caused by misoperation or control failure.

Working Principle of the Hoisting Height Limit Switch

The hoisting height limit switch usually operates synchronously with the hoisting mechanism. Its basic logic includes:

●The hook rises with the hoisting mechanism.

●The preset height position is reached.

●The limit switch is triggered.

●The control system cuts off the hoisting direction circuit.

●Hoisting stops to prevent further upward movement.

In modern cranes, height limit switches are deeply integrated with electrical control systems. This enables precise triggering, fast response, and stable control. It effectively avoids risks caused by human misjudgment.

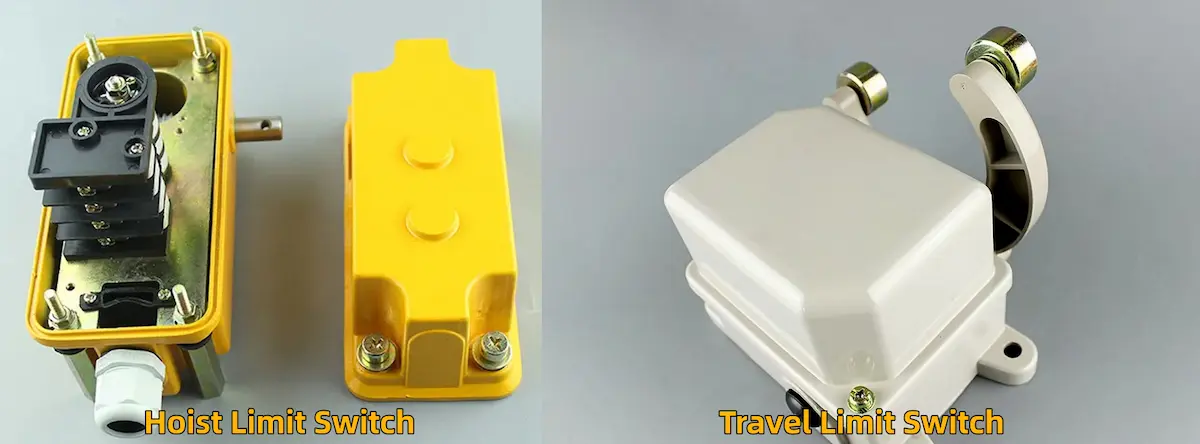

Common Types of Hoisting Height Limits

|

Item |

Mechanical Hoisting Height Limit |

Electrical Hoisting Height Limit |

| Trigger Method | Triggered by levers, cams, or counterweights linked to the hoisting mechanism | Detects hook height using encoders, limit switches, or sensors |

| Structural Features | Lower control accuracy, mainly provides ultimate protection | High control accuracy, supports single-stage or multi-stage limits |

| Operational Stability | Independent of electrical systems, high stability | Relies on electrical components, requires reliable control systems |

| Typical Applications | Used as basic or auxiliary safety protection | Suitable for highly automated and high-frequency cranes |

| Configuration Role | Often used as final limit protection | Often used as working or pre-limit protection |

In practical engineering applications, high-end or heavy-duty cranes often use both mechanical and electrical height limits. This redundant design improves overall safety levels. It ensures reliable protection under various conditions and abnormal situations.

What Is a Crane Travel Limit Switch

During crane operation, safety control in the traveling direction is as important as hoisting safety. Crane travel limit switches are key safety components controlling safe horizontal movement.

Definition and Functions of Travel Limit Switch

A crane travel limit switch is a safety protection device used to restrict the maximum travel distance of the crane or trolley along rails or girders.

When the crane or trolley reaches a preset limit position, the travel limit switch activates automatically. It cuts off the corresponding travel power or control signal. This stops further movement and prevents overtravel hazards.

Its main functions include:

●Preventing crane or trolley movement beyond safe travel ranges.

●Avoiding collisions with end beams, rail stops, or other equipment.

●Reducing risks of structural deformation or derailment.

●Ensuring long-term stability of crane travel systems.

Control Targets of Travel Limits

|

Control Item |

Crane Travel Limit |

Trolley Travel Limit |

| Control Range | Controls overall crane travel along workshop rails | Controls trolley travel along the main girder |

| Main Function | Limits maximum crane positions at both rail ends | Limits maximum trolley positions at girder ends |

| Common Installation Locations | Rail ends, crane end beams, or travel mechanisms | Girder ends or near trolley travel rails |

| Protection Focus | Prevents collisions or derailment at rail ends | Prevents trolley impact with girder ends or buffers |

| Applicable Crane Types | Overhead cranes and gantry cranes | Overhead cranes and gantry cranes with trolley systems |

| Safety Significance | Protects overall crane structure and operation | Protects hoisting mechanisms and main girder structures |

Through separate configuration and coordinated control of crane and trolley travel limits, horizontal movement systems receive comprehensive safety protection. This effectively reduces collision, derailment, and structural damage risks.

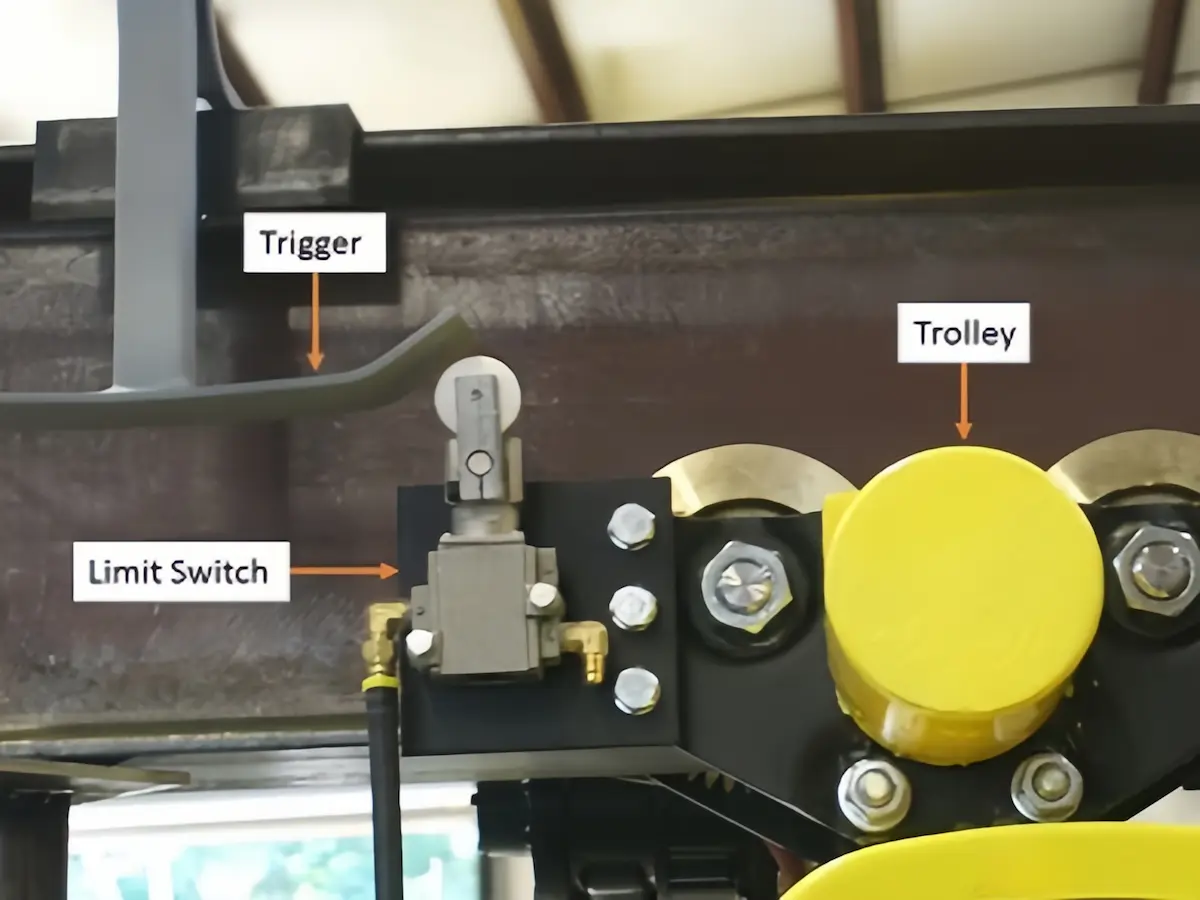

Working Mode of Travel Limit Switch

Travel limit switches usually operate synchronously with travel mechanisms. Their basic working mode includes:

●The crane or trolley moves along the rail.

●It approaches the preset travel limit position.

●The travel limit switch is triggered.

●The control system cuts off the corresponding travel circuit.

●The travel mechanism stops to prevent further movement.

In practice, travel limits include working travel limits and ultimate travel limits. Some cranes also combine buffers and end stops. This creates multi-level safety protection systems. It further improves overall operational safety levels.

Core Differences Between Height Limit Switches and Travel Limit Switches

|

Comparison Dimension |

Height Limit Switch |

Travel Limit Limit Switch |

| Controlled Object | Hoisting mechanism, including hook, wire rope, and drum. | Travel mechanism, including crane travel and trolley travel. |

| Direction of Action | Vertical direction, controlling lifting height. | Horizontal direction, controlling travel distance. |

| Main Risks Prevented | Hook overhoisting, excessive wire rope winding, hoisting mechanism damage. | End beam collision, equipment impact, derailment, structural deformation. |

| Typical Accident Types | Hook striking sheave block, wire rope breakage, motor overload. | Crane end collisions, rail damage, travel mechanism failure. |

| Common Installation Locations | Hoisting mechanism, drum shaft end, sheave block, or trolley frame. | Rail ends, girder ends, end beams, or near travel mechanisms. |

| Control Method | Mechanical or electrical, dual configuration possible. | Mechanical or electrical, with working and ultimate limits. |

| Maintenance Focus | Limit trigger sensitivity, wire rope and drum wear. | Limit position accuracy, buffer condition, and rail status. |

| Safety System Significance | Prevents irreversible hoisting damage and ensures lifting safety. | Prevents travel collisions and ensures operational safety. |

Height limit switches and travel limit switches act on vertical and horizontal systems respectively. Their functions cannot replace each other. Only proper configuration of both devices ensures a complete crane safety protection system. This approach effectively reduces various operational safety risks.

Common Misunderstandings and Selection Recommendation for Limit Limit Switch

In actual crane use and selection, limit switches are often ignored with a “set and forget” mindset. Experience from numerous accidents and equipment failures shows that proper limit switch configuration directly determines crane safety levels.

Issue 1: Overemphasis on travel limit switch, neglecting height limit switch risks

Common problems

In some projects, clients focus more on controlling crane travel range, while safety control of lifting height is insufficient. They may only install basic height limit switches or fail to adjust and maintain them over time. Once the height limit fails or is improperly set, hook overtravel, wire rope entanglement, and other issues can occur, causing minor damage to the hoisting mechanism or severe safety accidents.

Recommendations

Height limit switches are the core safety line for the hoisting system and should not be optional. Practical suggestions include:

●Hoisting mechanisms must be equipped with reliable height limit switches

●Use dual protection with mechanical and electrical height limits in critical conditions

●Set limit positions reasonably based on building height and actual lifting requirements

Issue 2: One-size-fits-all limit switch configuration under different conditions

Common problems

Some projects directly apply standard configurations during crane selection without considering actual conditions such as building height, span, travel route, and usage frequency. This may result in insufficient redundancy or low protection levels. Such “one-size-fits-all” setups often expose safety risks under high-frequency use or complex conditions.

Recommendations

Limit switch configuration should be based on operational conditions:

●High-lift, high-frequency operations require multi-level height limits and precise travel limits

●Cranes with large spans or complex travel routes should strengthen main and trolley travel limit setups

●Automated or intelligent cranes should adopt high-reliability electrical limit switches with redundancy

Targeted configuration can significantly enhance overall safety without excessive cost.

Issue 3: Neglecting regular inspection and maintenance

Common problems

After equipment commissioning, some users prioritize productivity over regular inspection and maintenance of limit switches. This can cause switches to become insensitive, misaligned, or fail. Once a limit switch fails, its protection becomes meaningless, and safety risks multiply.

Recommendations

Limit switch inspection and maintenance should be included in routine crane safety management:

●Regularly check if limit switches are sensitive and accurately positioned

●Adjust or replace components promptly if anomalies are found

●Include limit switch inspection in annual and daily crane checks

Ensuring limit switches are always functional allows them to provide the intended safety protection.

HSCRANE Crane Safety Protection System Advantages

●Multiple Safety Protection Design: Dual redundancy of height limit and travel limit ensures both hoisting and travel systems are controlled, enabling stable and reliable operation.

●High-Reliability Electrical Components: Industrial-grade components resist high frequency and interference, suitable for complex conditions and continuous operation, ensuring stable performance.

●Customized Safety Solutions: Limit switches are precisely designed based on building height, span, travel route, and operating conditions, balancing safety and efficiency.

●Compliance with International Safety Standards: Design follows CE, ISO, and other global crane safety norms, meeting high safety and compliance requirements worldwide.

●Proven Application Experience: HSCRANE limit switches are widely used in manufacturing, logistics, steel, and power industries. Long-term operational cases prove reliability and practicality, offering sustainable and secure crane operation.

Safety protection systems form the baseline of crane design and are critical for long-term stable operation. Both height limit and travel limit switches must be properly configured and regularly maintained to reduce accident risk and protect personnel and equipment. Choosing a reliable safety system protects not only the crane but also production safety and operational efficiency.

Contact HSCRANE to tailor full safety protection for your crane, enabling efficient, durable, and safe operation.

For more on crane safety components, see What Types of Crane Limit Switches Are There? A Comprehensive Guide to Their Functions, exploring mechanical and electrical limit switch characteristics, working principles, and practical applications for more reliable safety configuration.

FAQ

Q1: What is the difference between height limit and travel limit on a crane?

A1: Height limit controls the vertical hoisting of the hook, preventing overtravel and wire rope damage. Travel limit controls the trolley and crane movement horizontally, preventing collisions and derailments. Both form the crane safety system but differ in direction and control objects.

Q2: Why configure both mechanical and electrical height limits?

A2: Mechanical height limits are stable and reliable, functioning during power loss or abnormal conditions. Electrical height limits are precise and fast-responding, allowing multi-level limits. Dual configuration adds redundancy and enhances safety.

Q3: How do travel limit switches ensure trolley and crane safety?

A3: Travel limits control the trolley’s horizontal movement on the main beam and the crane’s overall travel along the runway, preventing collisions with end beams, tracks, or other equipment, reducing structural damage and derailment risk.

Q4: How often should limit switches be inspected?

A4: Include limit switch inspection in daily checks and annual inspections to ensure sensitivity and accurate position. Adjust or replace parts immediately if anomalies are found.

Q5: What are common limit switch faults? Why does a limit switch not work?

A5: Common issues include contact wear or burn, internal spring failure, misaligned installation preventing triggering, and loose wiring or control circuit faults. Limit switch not working often results from damaged contacts, misalignment, or wiring problems. Dust and humidity may also cause malfunctions and require prompt inspection and replacement.

Q6: What conditions are HSCRANE safety protection systems suitable for?

A6: HSCRANE systems are customizable based on building height, span, travel route, and usage frequency, suitable for complex conditions in manufacturing, logistics, steel, and power industries.

This document is for reference only. Specific operations must strictly comply with local laws and regulations and equipment manuals.