In modern industrial lifting operations, crane tongs have become indispensable equipment for handling steel materials, plates, and bulk goods. Compared with traditional lifting devices, crane tongs provide more stable load control through a clamping mechanism, enabling lifting tasks to be performed with greater precision and safety. As industries demand higher efficiency and lower operational risks, accuracy, safety, and productivity have become key performance indicators for lifting equipment. The structural quality, clamping method, and reliability of the tong directly determine overall lifting performance and workplace safety. High-performance crane tongs significantly improve operational precision, reduce manual intervention, minimize material damage, and ultimately create higher value for enterprises.

Main Types of Crane Tongs

Steel Coil Tongs

Designed for vertical or horizontal lifting of steel coils, these are among the most widely used tongs in steel mills.

Features & Advantages:

- Clamp arms are professionally engineered to precisely fit the outer diameter of the coil

- Equipped with anti-slip pads to reduce edge damage

- Available in ring-type, C-type, suspended and other configurations for vertical and horizontal lifting

Applications: Steel mills, warehouses, processing centers

Vertical Plate Tongs

Used for vertical lifting and handling of steel plates or sheets—ideal for thin or large-size plates requiring precise and safe movement.

Features & Advantages:

- Vertical clamping minimizes plate swing during lifting

- High-friction jaws prevent slippage

- Automatic locking mechanisms enhance lifting safety

Applications: Steel fabrication, manufacturing, warehouse logistics

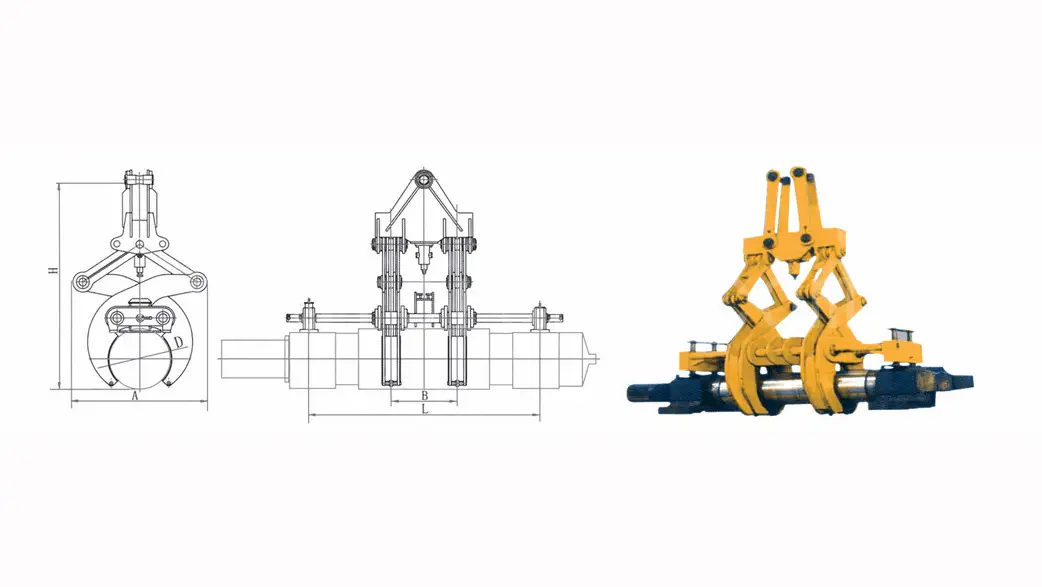

Billet Tongs

Designed specifically for billets, profiles, and long materials, with emphasis on balanced force distribution and stability.

Features & Advantages:

- Even stress distribution prevents off-balance loads or slipping

- Strong clamping force, suitable for high-temperature and heavy-duty operations

- Optional multi-point clamping for enhanced lifting safety

Applications: Continuous casting lines, furnace outlets, steel processing areas

Horizontal Plate Tongs

Used for horizontal transportation of steel plates or slabs, ideal for flat material conveying.

Features & Advantages:

- Clamp arm design ensures plates remain level during lifting

- Minimizes bending and edge deformation—suitable for high-surface-quality materials

- Compatible with automated systems for single or multi-plate handling

Applications: Cutting lines, processing lines, conveying systems

Automated & Custom-Engineered Tongs

Tailored for smart manufacturing or special material handling needs.

Features & Advantages:

- Optional sensors, encoders, and load monitoring modules

- Supports automatic positioning, auto-clamping, and remote operation

- Custom-designed jaws for irregular, oversized, or complex components

Applications: Smart factories, robotic workstations, unmanned lifting systems

Core Structural Features of Crane Tongs

- High-Strength Frame Structure: Crane tongs are built with high-strength alloy steel or wear-resistant structures, optimized via FEA to ensure stability under heavy loads and high-frequency operations. The robust frame resists deformation and fatigue, extending service life.

- Adjustable Clamp Arms & Multiple Jaw Designs: Adjustable clamp arms accommodate different material sizes and shapes, enhancing lifting flexibility. Custom jaw options ensure precise, stable gripping while reducing slippage and off-center loads.

- Hydraulic / Mechanical Drive Systems: Hydraulic systems deliver strong, controllable clamping force for high-precision and frequent-use applications. Mechanical drives feature simple maintenance and stable performance, suitable for environments prioritizing low maintenance.

- Automatic Locking & Safety Interlock Mechanisms: Crane tongs typically include gravity-locks, mechanical self-locks, or linkage systems to prevent accidental release. Safety interlocks coordinate with crane movements to avoid misoperation and provide load protection.

- Protective Pads & Anti-Slip Surfaces: To prevent material surface damage, jaws are equipped with rubber, nylon, or specialized anti-slip pads. Enhanced grip ensures safe handling even in oily, hot, or humid environments.

Working Principle of Crane Tongs

The working principle of crane tongs relies on the coordinated action of gravity self-locking, mechanical transmission, and hydraulic control mechanisms to achieve stable and secure clamping. The core concept is the utilization of a gravity-driven self-locking mechanism that causes the clamp arms to automatically close when loaded, ensuring the material remains firmly secured throughout the lifting process. Meanwhile, the internal mechanical linkage system synchronizes the movement of both jaws during opening and closing, preventing off-center loading and uneven force distribution. For applications requiring higher precision, the hydraulic system can precisely regulate clamping force based on the weight and shape of the material, delivering a smoother and more reliable clamping performance. In scenarios with advanced automation requirements, crane tongs may be equipped with sensors, load monitoring, and position feedback modules to achieve real-time monitoring, automatic adjustment, and safety warnings—making lifting operations safer, more efficient, and highly controllable.

Typical Application Scenarios for Crane Tongs

|

Industry |

Typical Material / Workpiece Types |

Application Insights |

| Steel and Metallurgy | Steel coils, steel plates, billets, profiles, round billets | Extremely high requirements for load capacity, heat resistance, and stability. Crane tongs are used in rolling line unloading, internal transfer, and warehouse stacking, ensuring safe and efficient material handling. |

| Ports, Logistics, and Warehousing | Bulk materials, general cargo, plates, bundled goods | Crane tongs can replace traditional lifting methods with faster gripping and positioning, increasing port throughput. They perform reliably in handling bulk cargo, sorting yards, and outdoor environments. |

| Manufacturing & Assembly | Steel structures, semi-finished products, machined parts, modular components | High precision handling requirements. Tongs ensure accurate gripping and balanced movement, ideal for material transfer, feeding operations, and positioning in assembly processes. |

| Building Materials Industry | Cement bags, construction boards, pipes, bricks, packaged materials | Customized jaws and anti-slip structures allow fast transfer of bagged goods, boards, and finished materials, improving warehouse efficiency while reducing manual labor intensity. |

| Smart Factory Automation | Automated production line materials, finished modules, custom components | With sensors, auto-locking, and remote monitoring, crane tongs can integrate with AGVs, automated cranes, and MES systems, supporting digital factories and intelligent warehousing. |

Core Advantages of HSCRANE Crane Tongs

- Professional Customization for Industry-Specific Conditions: HSCRANE designs crane tongs tailored to various industrial environments such as steel plants, ports, shipyards, and equipment manufacturing. Every parameter—material size, temperature conditions, working frequency, and matching crane type—is customized to ensure optimal performance in real-world operations.

- High-Strength Structural Design and Long-Term Durability: All crane tongs are manufactured using premium alloy steel and undergo FEA structural optimization. This results in lighter yet stronger designs with excellent fatigue resistance. Longer maintenance intervals reduce overall operational costs and ensure suitability for heavy-duty, high-frequency industrial work environments.

- Stable and Precise Clamping Performance: HSCRANE crane tongs deliver outstanding stability through anti-slip pads, mechanical locking mechanisms, and limit protection features. These designs ensure precise and controllable lifting operations, especially important in environments requiring high accuracy and fast operating rhythm.

- Multiple System Options: Mechanical, Hydraulic, and Automated: HSCRANE offers mechanical, hydraulic, and smart automated tong solutions based on customer production requirements. Optional modules include remote control, sensor monitoring, automatic positioning, and more—supporting automated factories, unmanned production lines, and other advanced applications to enhance safety and efficiency.

- Rigorous Factory Testing & Global Application Experience: Every crane tong undergoes strict factory testing, including load tests, motion tests, and safety verification. HSCRANE products are widely used across the Middle East, Southeast Asia, Europe, and other regions, operating long-term under complex conditions with highly reliable performance and strong customer recognition.

Selection Guide: How to Choose the Right Crane Tong

|

Selection Factors |

Key Considerations |

Application Recommendations |

Alternative Notes |

| Material Condition, Weight, Surface Requirements | Is the material steel coil, plate, billet or bulk material?Single-piece weight and sizeIs surface extrusion allowed?Is surface protection required? | Steel coil → Steel Coil Crane TongSteel plate → Vertical/Horizontal Plate Crane TongBillet/steel section → Billet/Section Crane TongSurface-sensitive material → Equipped with protective pad | Lightweight material: lightweight structureHeavy-load material: high-strength designSurface precision material: soft protective claw |

| Ambient Temperature & Operation Frequency | Is it high temperature?Is it high dust, humidity or corrosive?Is operation frequency high?Is 24h continuous operation required? | High temperature → Mechanical or high-temperature hydraulic systemHigh-frequency operation → Hydraulic drive or automated deviceGeneral environment → Mechanical drive | High temperature/high-frequency environment: avoid low-strength componentsSelect wear-resistant, fatigue-resistant design |

| Automation & Safety Monitoring Requirements | Is remote control required?Is automatic clamping required?Is automatic material detection required?Is load monitoring required?Is position feedback required? | Automated factory → Automated Crane Tong + sensor moduleHigh-safety scenario → Tightening control + limit structure + load monitoring | Automation improves precision and safety, but higher costSuitable for large/medium factories or smart production lines |

| Manufacturer’s Technical Capability & Quality Assurance | Is structural simulation capability available?Is non-standard customization supported?Is there a mature case and testing system? | It is recommended to choose manufacturers with industry experience, customization capability and strict testing systems (e.g., HSCRANE) to ensure long-term reliable operation of the tong in actual working conditions | Experienced manufacturers can provide working condition analysis, life evaluation and global after-sales supportReduce operational risks and later maintenance costs |

Crane tongs play an irreplaceable role in modern industrial lifting. Their precise gripping, safety control, and efficient operation directly determine material-handling efficiency and the overall stability of industrial processes. Choosing a crane tong that truly matches the working conditions not only improves production efficiency but also provides the best assurance for safety, operational cost, and long-term investment.

When purchasing, it is crucial to prioritize manufacturers with strong customization capability, extensive industry experience, and the ability to adapt to global working conditions. Relying on a mature engineering design system, strict testing standards, and proven global cases, HSCRANE provides reliable customized crane tong solutions for steelmaking, ports, manufacturing, and fully automated factories.

Make lifting more precise, safer, and more efficient. Contact HSCRANE now to get your customized solution!

If you’re still exploring the right lifting attachments, continue reading Crane Hooks: Types, Applications, and Safety Standards in Industrial Lifting for a more comprehensive reference.