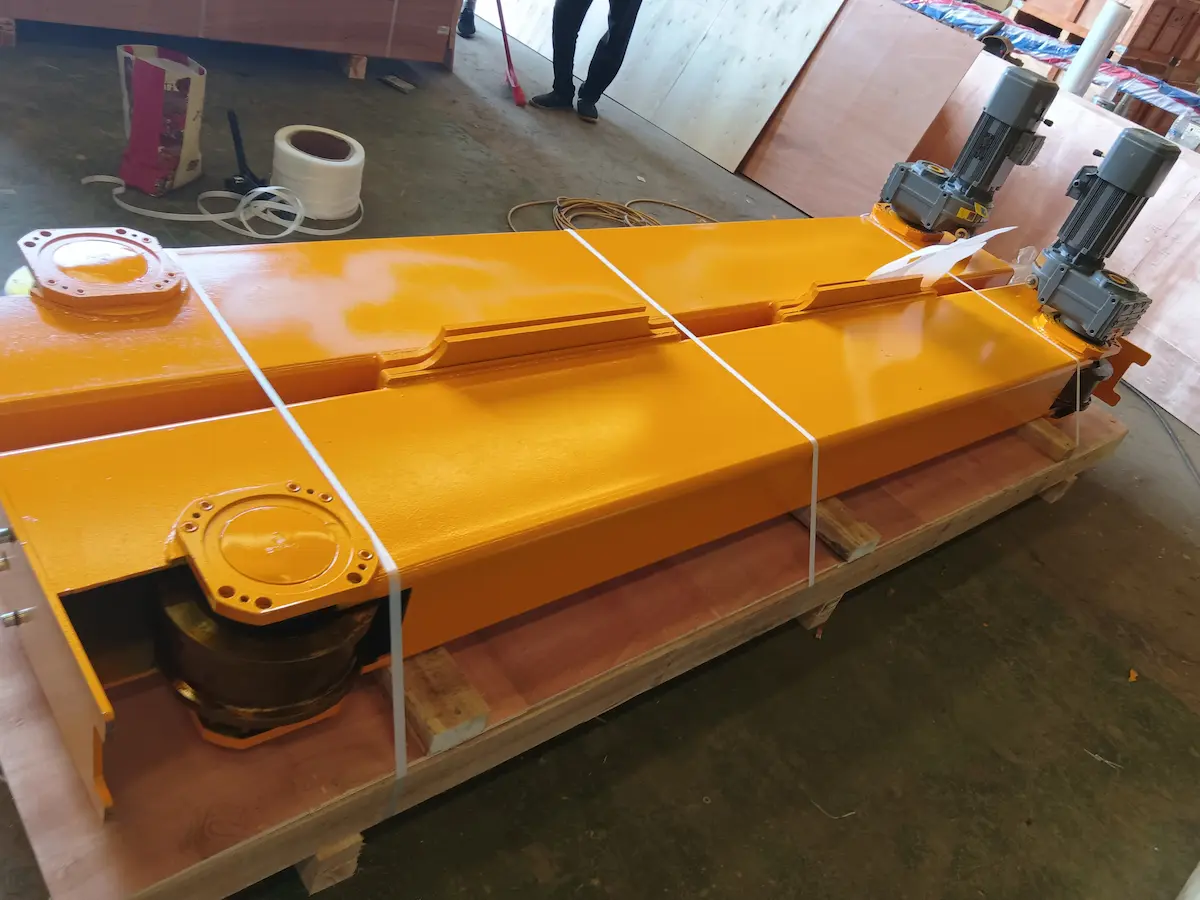

The crane end beam is the terminal structure of the bridge frame, connecting to the main girder and mounting the traveling wheels.It primarily supports the crane’s movement along the rails.Inside the end beam are usually integrated a drive motor, gearbox, and wheel set.These components transmit power to the entire crane, enabling longitudinal motion.In bridge cranes, the end beam supports the structure moving on elevated rails.In gantry cranes, it connects to the legs, bearing the gantry frame and traveling on ground rails.Because the end beam’s quality and precision directly affect crane safety, lifespan, and efficiency,understanding its structure and working principle is essential for selecting the right model,ensuring stable operation, and performing effective maintenance.

What Is a Crane End Carriage?

Definition of End Beam:The end beam is a structural unit installed at both ends of the crane bridge.It connects with the main girder and enables the crane to travel along the rails.

Main Functions of the End Beam

- Support the main girder and distribute loads:It connects directly with the main girder to form a stable frame.The end beam transfers the weight of the load and the structure evenly to the traveling mechanism and rails, preventing deformation or fracture.

- Install wheels and fix traveling components:The lower part of the end beam is equipped with a wheel set, which is the key contact point between the crane and the rail.It bears the total weight and lifting load, ensuring smooth rolling while protecting components and reducing wear.

- Drive the crane’s movement:The end beam usually contains a motor, reducer, and brake system.These components transmit power to the wheels, moving the crane along the rails.The brake locks the wheels when needed, preventing inertial sliding and ensuring safety.

Common Structures of the End Beam

- Welded box-type structure:The end beam is typically made of high-strength steel plates welded into a box-type structure with internal stiffeners.This design enhances rigidity and torsional resistance, providing moderate weight, high load capacity, and reduced vibration and deformation during operation for smoother crane travel.

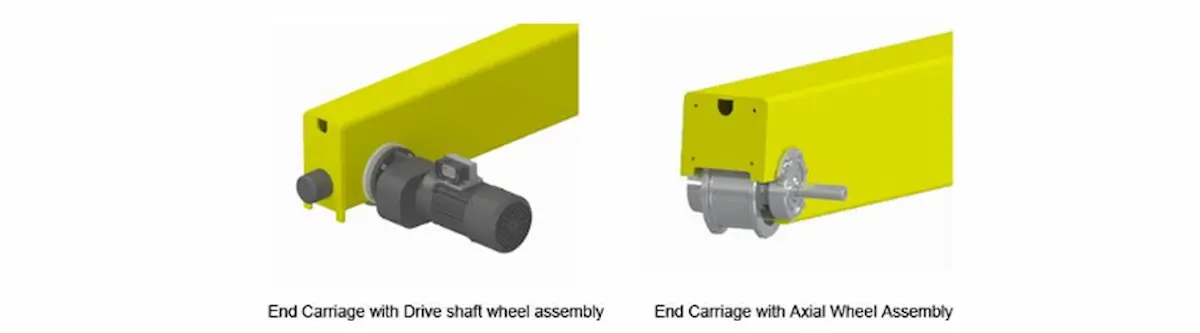

- Driven and idler ends configuration:

A crane usually has two end beams:

- Driven end: Equipped with a motor, reducer, and coupling, it drives the crane through powered wheels.

- Idler end: Lacks power devices and moves passively through idler wheels to maintain bridge balance and guidance.

- Overall, the structural design of the end beam directly affects the crane’s operational stability, lifespan, and maintenance convenience.It is a critical component in both bridge and gantry cranes.

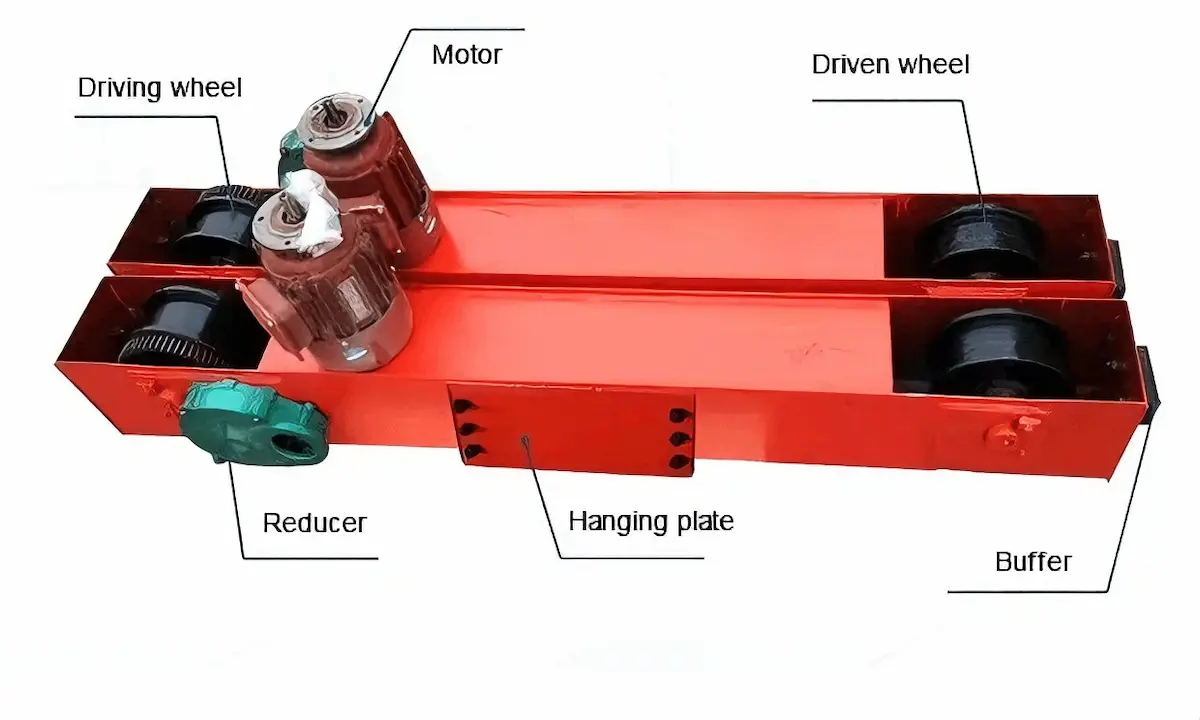

- Wheels & Bearings:The wheel is a key component of the crane’s traveling system.It is usually installed beneath the end beam and bears the crane’s total weight and load.With high-precision bearings, it ensures smooth crane movement, reduces friction, and extends service life.

- Drive Unit / Motor + Gearbox:Installed on the driven end beam, the motor and gearbox transmit power through the drive system to the drive wheels, enabling the crane’s longitudinal movement.The drive unit must ensure high transmission efficiency, low noise, and reliable braking performance.

- Coupling & Shaft Connection:The coupling connects the gearbox to the motor or wheel shaft, compensating for minor misalignments and transmitting torque.The drive shaft transfers power between the two wheels, ensuring synchronized rotation and preventing rail deviation.

- Buffer & Wheel Guard:Both ends of the end beam are typically equipped with rubber, spring, or polyurethane buffers to absorb impact at the travel path’s endpoint.Some designs also include protective covers and anti-collision blocks to ensure safe operation and protect internal components.

- Electrical Connection & Limit Switch:The electrical system includes motor terminals, conductor bar or cable reel connections, and travel limit switches.The limit device automatically cuts power before the end beam reaches the rail’s end, preventing derailment.

Types of Crane End Carriages

Single Girder End Carriage

- Structural Features:Single-girder end beams are typically used for single-girder bridge or gantry cranes.They consist of two short, independent end beams welded or bolted to both ends of the main girder.The cross-section is usually a simplified box or channel type, giving a compact, lightweight structure.

- Applicable Scenarios:Commonly used in workshops, warehouses, or assembly areas with medium duty, small span, and moderate lifting capacity.

- Key Advantages:With a simple design, it offers low manufacturing and maintenance costs.It is easy to install, space-saving, and energy-efficient during operation.

Double Girder End Carriage

- Structural Features:Commonly used in double-girder bridge or gantry cranes, it consists of two long box-type end beams.These are rigidly connected to both main girders with high-strength bolts, enhancing overall load capacity.The end beam has a larger cross-section with internal diaphragms for greater torsional and load resistance.It often includes multiple wheel sets and independent drive units to ensure synchronized crane movement.

- Applicable Scenarios:Ideal for heavy-duty, high-frequency, or long-span operations in industrial plants, steel mills, shipyards, and ports.

- Key Advantages:Offers smooth operation and high load capacity.Can be equipped with large electric hoists or trolleys to meet complex lifting requirements.

Top Running vs. Under Running

|

Comparison Dimension |

Top-Running Bridge Crane End Beam |

Under-Running Bridge Crane End Beam |

| Installation Position | Installed below or outside both ends of the main girder, traveling on top of the rail. | Installed above or level with the main girder, the crane hangs beneath the rail. |

| Traveling Method | Moves along rail beams or rails mounted on column tops. | Suspended from the lower flange of the rail or I-beam. |

| Structural Form | Welded box-type structure with high rigidity and torsional strength. | Lightweight structure, often welded with channel or square tubes. |

| Wheel Arrangement | Wheels positioned at the bottom of the end beam, bearing downward pressure. | Wheels positioned above the end beam, bearing upward hanging force. |

| Drive Configuration | Ample space allows separate driving and idler ends with strong power output. | Limited space; typically uses a single motor or chain drive system. |

| Load Capacity | Suitable for heavy loads, long spans, and high-frequency operations. | Suitable for light loads, short spans, and low-duty applications. |

| Operating Characteristics | Smooth and fast movement, ideal for long travel distances. | High positioning accuracy, slower speed, suitable for short-distance handling. |

| Application Scenarios | Heavy manufacturing, metallurgy, ports, and warehousing logistics. | Assembly lines, light workshops, and height-restricted warehouses. |

Differences in Working Conditions and Load Capacity

The design of the end beam directly affects the crane’s load capacity, operating conditions, and application scenarios.

|

Comparison Dimension |

Single-Girder End Beam |

Double-Girder End Beam |

| Structural Features | Supports a single main girder; lightweight structure. | Supports two main girders; high rigidity structure. |

| Load Capacity | Suitable for light to medium loads. | Suitable for medium to heavy loads. |

| Span & Travel | Small to medium span; medium-short travel. | Medium to large span; long travel; suitable for large factories or ports. |

| Installation Method | Can be top- or under-running; suitable for lightweight operations. | Usually top-running; under-running possible, but heavy loads generally use top-running. |

| Usage Frequency | Medium to low frequency; light or intermittent operations. | High frequency; heavy-duty continuous operations. |

| Operating Environment | Warehouses, assembly workshops, light production lines. | Steel mills, shipyards, port logistics, large manufacturing plants. |

How to Choose the Right End Carriage

- Select by crane type:The crane type determines the basic structure and load requirements of the end beam.Single-girder electric cranes fit single-girder end beams, composed of two short independent beams, suitable for medium to small loads.Double-girder bridge or gantry cranes require long box-type double-girder end beams, rigidly bolted to both main girders for higher torsion resistance and load capacity, suitable for heavy-duty and high-frequency operations.

- Select by span:End beam design must match the crane span.Small spans use lightweight beams focusing on stability and load capacity.Medium to large spans require enhanced torsional and bending resistance.For extra-large cranes, finite element analysis is recommended to optimize structure for long-term safety and lifespan.

- Select by working class:Crane working class (A3–A5) reflects usage frequency and load conditions.A3 cranes with low frequency and light loads can use moderate-capacity, simple end beams.A5 cranes with high frequency and heavy, variable loads require higher-quality beams with larger cross-sections and superior material performance for reliability and safety.

- Select by drive type:The end beam must match the drive system for smooth operation.Direct motor drive is simple and responsive but requires high flatness and rigidity.Coupling drive suits heavy or long-span cranes, requiring reserved supports for reducers, couplings, and precise shaft alignment.

- Select by customization and interface requirements:End beams serve as both structural and functional platforms.HSCRANE can provide cable slots, limit switches, grounding terminals, and conductor bar interfaces.For outdoor or corrosive environments, hot-dip galvanizing, anti-corrosion coating, or stainless-steel structures are available.Non-standard bridges or factory structures can use 3D modeling to ensure perfect interface and dimensional fit.

- Procurement Considerations:

Confirm structural parameters, interface dimensions, and drive layout match the crane.

Check welding inspection reports, material certificates, and installation tolerances.

Choose manufacturers with complete supply chains and service systems.

HSCRANE offers end beam solutions for bridge, gantry, and jib cranes, supporting standard and customized integration, helping clients achieve safe and efficient material handling systems.

Maintenance and Troubleshooting Tips

Daily Inspection Key Points

- Wheel and Rail Wear:

Inspect wheel tread and flange for wear, spalling, or misalignment.

Ensure wheel diameters at both ends meet manufacturing tolerances to prevent skewed travel.

- Connection Bolts and Welds:

Check if end beam-to-main girder bolts are loose.

Inspect welds for cracks or corrosion; tighten or repair immediately if abnormalities are found.

- Drive Motor and Gearbox:

Monitor motor temperature to ensure it remains within rated limits.

Check gearbox for oil leaks, abnormal noise, and loose bearings.

- Electrical System and Limit Devices:

Test travel limit switches and emergency stop devices for sensitivity and reliability.

Ensure cables or conductor bar connections are secure, undamaged, and properly fastened.

Common Faults

|

Fault |

Possible Cause |

Suggested Action |

| Vibration or unstable motion | Uneven wheel wear, uneven rail, loose gearbox | Correct rail alignment, replace wheels, check drive connections |

| Excessive noise | Worn bearings, poor gear meshing, misaligned coupling | Replace bearings, adjust gear clearance, recalibrate coupling |

| Off-track running | Unequal wheel diameters, end beam geometric deviation, non-parallel installation | Correct end beam balance, check rail gauge, realign |

| Motor overheating or vibration | Unbalanced power supply, brake slip, excessive load | Check voltage, adjust brake, reduce load |

Periodic Lubrication and Calibration Recommendations

- Lubrication Cycle:Add grease every 250–500 operating hours or based on usage frequency.Key lubrication points: wheel bearings, gearbox, couplings, and drive shaft supports.

- Calibration and Maintenance:Check end beam and rail parallelism and wheel load distribution every six months.Inspect end beam geometry and installation position for deviations to ensure synchronized operation.

Choosing HSCRANE means choosing professionalism and reliability.With years of crane manufacturing experience, HSCRANE delivers high-quality bridge, gantry, and customized cranes worldwide.All products strictly follow FEM/DIN international design standards, ensuring structural safety, stable performance, and longer service life.HSCRANE can tailor end beam and complete crane solutions to customer operating conditions for precise fit and efficient operation.Supported by a comprehensive global delivery and technical support network, we respond quickly to overseas demands, ensuring timely delivery and worry-free production.