As China rises as a global manufacturing leader, demand in the crane industry continues to grow steadily. Cranes play a vital role in ports, construction sites, and industrial production lines. Selecting a reliable crane parts supplier has therefore become essential. High-quality crane components are critical for safety and reliability. They also affect operating efficiency, maintenance costs, and service life. In this demanding industry, choosing a supplier that provides parts meeting international standards is the foundation of safe and efficient long-term operations. Understanding how to choose wisely among many suppliers is key to project success and equipment safety.

Why China Is the Best Source for Crane Parts

- Competitive Pricing and Flexible Manufacturing: China offers strong production capacity and flexible manufacturing. Suppliers provide competitive pricing for both mass production and customized needs.

- High Standards and International Certifications: Many Chinese suppliers hold ISO, CE, and FEM certifications. Their parts meet global safety, quality, and environmental standards, supporting compliance in various regions.

- Wide Range of Parts for All Crane Types: Chinese suppliers offer complete part ranges for bridge cranes, gantry cranes, and other lifting equipment. Products include hooks, motors, wheels, limit switches, controllers, and more.

- Fast Delivery and Stable Supply Chains: China has advanced logistics systems that support quick delivery and strong global responsiveness. A stable supply chain ensures on-time shipping and reduces project delays.

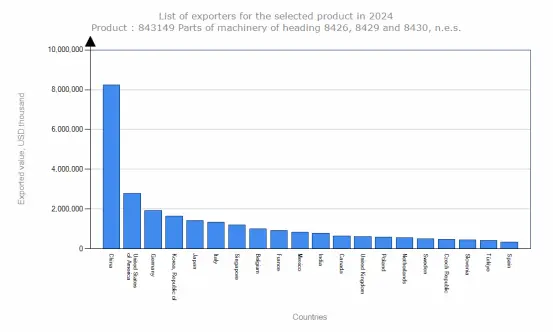

Taking the global export value of gantry crane parts in 2024 as an example

Common Challenges When Purchasing Crane Parts from China

- Inconsistent Quality: Supplier quality varies due to the large number of manufacturers. Some lack strict quality control, causing unstable part performance and safety risks.

- Long Lead Times or Unexpected Delays: International shipping and customs procedures may extend delivery cycles. Supply chain disruptions can also delay parts and affect project schedules.

- Communication Barriers: Language and cultural differences may cause misunderstandings in technical discussions. This can reduce procurement efficiency and lead to specification errors.

- OEM vs. Aftermarket Parts Selection: Buyers often balance cost, quality, and availability. OEM parts offer higher quality but higher prices. Aftermarket parts are cheaper but may vary in quality.

- These challenges require buyers to choose suppliers carefully. Effective measures include selecting certified manufacturers, ensuring clear communication, and tracking deliveries closely to reduce risk.

Key Factors to Evaluate When Choosing a Supplier

- Manufacturing Capacity and Factory Scale: Assess the supplier’s production lines and factory size. Confirm their ability to support large orders. Check if they have advanced inspection tools and load-testing facilities to ensure quality control.

- Product Range and Technical Expertise: Select suppliers with a wide product line, offering hooks, motors, wheels, wire ropes, limit switches, and more. Their engineering capability and innovation are also important to ensure parts meet technical requirements.

- Quality Control System: Ensure the supplier has a complete quality system covering material sourcing, inspection, and final testing. Understand how they control quality from raw materials to finished parts.

- Certifications and Compliance: Confirm the supplier holds ISO, CE, and FEM certifications. These standards ensure global-level design, manufacturing, and quality management.

- Engineering Support and Customization: Evaluate their engineering support, especially the ability to design customized parts for special conditions. Reliable suppliers should offer full support from design to implementation.

- On-Time Delivery and Logistics Performance: Review their logistics system and delivery capability. Stable supply chain management is critical for timely delivery and project success.

- After-Sales Service and Technical Support: Choose suppliers who offer fast and professional service. Strong after-sales support helps reduce downtime when issues occur.

How to Verify a Reliable Crane Parts Supplier

|

Verification Step |

What to Check |

Why It Matters |

| Request factory photos or a virtual tour | Factory size, production lines, testing tools | Confirms real manufacturing capability, not a trading company |

| Request drawings and data sheets | Technical parameters, material specs, dimension drawings | Ensures parts meet requirements and avoid installation risks |

| Check cooperation with known crane brands | Brand partners, project records | Shows industry reputation and experience |

| Request samples or test reports | Sample quality, material tests, load tests | Best method to confirm part performance and reliability |

| Review customer feedback or case studies | Reviews, success cases, application scenarios | Evaluates real-world performance and stability |

| Confirm packaging quality and export ability | Export packaging, crate strength, documents | Ensures safe global transport and compliance |

| Assess responsiveness and communication | Reply speed, technical accuracy | Affects procurement efficiency and after-sales performance |

How HSCRANE Provides Reliable Crane Parts Solutions

HSCRANE uses 20+ years of crane manufacturing and engineering experience to support global customers with high-quality parts and fast service. We understand operational needs in different working conditions and deliver safe, accurate, and cost-effective spare-part solutions.

- 20+ Years of Crane Expertise: Deep industry experience ensures accurate matching for different crane brands and models. Our solutions are proven in long-term operation.

- Professional Engineering Team: Our engineers cover structure, electrical, drive systems, and hydraulics. We ensure correct part selection and provide solutions to complex issues.

- Full Range of Bridge and Gantry Crane Parts: HSCRANE offers electrical parts, drive components, structural items, brakes, pulleys, wire ropes, and more. One-stop supply reduces multi-channel costs.

- Customized Solutions for Special Conditions: We provide reinforced and customized parts for high-temperature, dusty, corrosive, or high-duty environments.

- Fast Delivery to Global Regions: With strong logistics and export experience, we offer urgent production and quick customs clearance to minimize downtime.

- Full Engineering Support from Design to After-Sales: HSCRANE provides design, selection, installation guidance, commissioning, and long-term support to help customers build a stable maintenance system.

Choosing a reliable crane parts supplier in China requires evaluating experience, product quality, one-stop capability, customization level, and international delivery strength. Only suppliers with strong engineering expertise, strict quality control, and complete after-sales service can ensure long-term safe and stable crane operation.

If you are looking for a dependable crane parts supplier in China, contact HSCRANE. We offer full-range parts, customized solutions, expert support, and fast global delivery.

Want to learn more about crane parts?

From electrical components to drive systems, and from pulleys and wire ropes to braking units, HSCRANE provides a full range of high-quality spare parts for all operating conditions.