In the operating system of an overhead crane, crane wheels are key components that directly bear the equipment’s weight and maintain contact with the rails. Their performance has a direct impact on running smoothness, operational safety, and service life. Crane wheels must not only withstand high wheel loads, but also maintain good wear resistance and stability under frequent starts and stops and long-term operation. Improper wheel selection can easily lead to a range of operational problems, such as severe rail gnawing, abnormal wear of the tread and flange, increased running noise, and even unstable crane travel. These issues increase failure rates and maintenance costs and may disrupt normal production.

Therefore, it is essential to evaluate actual operating conditions, gain a systematic understanding of the selection criteria and manufacturing processes for overhead crane wheels, and choose crane wheels that are scientifically and appropriately matched to the application. This approach helps improve overall equipment performance and ensures long-term, safe, and efficient crane operation.

Basic Functions and Types of Overhead Crane Wheels

Main Functions of Crane Wheels

▴Load bearing and wheel load transmission: Crane wheels are core components of an overhead crane, directly supporting the crane’s self-weight, rated lifting capacity, and dynamic loads generated during operation. Through contact between the wheels and rails, these loads are effectively transmitted to the rails and foundation structures. Wheel structural strength, material properties, and tread profile directly influence the uniformity of wheel load distribution, thereby affecting the service life of both the rails and the crane structure.

▴Ensuring smooth crane travel: Properly designed and selected crane wheels help maintain straight-line motion and smooth operation of the overhead crane, reducing running resistance and vibration. High-precision tread and flange matching reduces the risk of rail gnawing, lowers operating noise, and improves overall stability and safety.

Common Types of Crane Wheels

Classification by Flange Structure

▴Single-flange wheels: Simple structure with clear guiding function; suitable for most standard overhead crane applications.

▴Double-flange wheels: Provide stronger guidance and anti-derailment capability; commonly used in complex operating conditions or where higher rail accuracy is required.

▴Flangeless wheels: Typically used together with guide wheels or lateral guiding devices; suitable for systems with high travel accuracy requirements and good rail conditions.

Classification by Function

▴Driving wheels: Connected to the motor and gearbox to provide travel power. These wheels require high wear resistance and fatigue strength.

▴Driven wheels: Do not provide driving force; mainly responsible for load bearing and guidance to ensure smooth travel.

Classification by Degree of Customization

▴Standard wheels: Standardized dimensions and parameters, short delivery cycles, suitable for general operating conditions.

▴Non-standard customized wheels: Designed according to lifting capacity, wheel load, rail specifications, and special operating conditions. They are better suited for heavy loads, high-frequency operation, or special environments.

Key Factors in Overhead Crane Wheel Selection

|

Selection Factor |

Main Considerations |

Impact on Wheel Selection |

| Lifting capacity and wheel load calculation | Loads from crane self-weight, rated load, and dynamic effects during operation | Determines wheel diameter, width, and material strength grade to prevent tread deformation and rail damage |

| Duty class and operating frequency | Reflects travel frequency and load variation | High duty classes require wheels with high wear resistance and fatigue strength to extend service life |

| Travel speed and drive mode | Crane travel speed; high-speed or low-speed operation; centralized or decentralized drive | Affects wheel dynamic balance, tread accuracy, and proper configuration of driving and driven wheels |

| Rail type and compatibility | Rail model, rail head width, installation accuracy | Ensures proper tread–rail contact, reducing rail gnawing, noise, and abnormal wear |

| Overall operating environment | Comprehensive environmental effects on wheel performance | Determines material selection, protection level, and surface treatment |

| High-temperature / low-temperature environments | High-temperature conditions or low-temperature/cold regions | High temperatures require thermal stability; low temperatures require good toughness to prevent brittle fracture |

| Indoor / outdoor operation | Stable indoor environments or variable outdoor conditions | Outdoor applications require enhanced rust and corrosion protection; indoor use focuses on durability under high-frequency operation |

By carefully considering these factors, overhead crane wheels can be optimally selected to match actual operating conditions, improving reliability, reducing maintenance requirements, and ensuring stable, long-term crane performance.

Common Materials for Crane Wheels and Performance Comparison

During long-term load-bearing and operation, crane wheels must simultaneously provide high strength, wear resistance, and fatigue resistance. Different manufacturing materials show clear differences in microstructure, mechanical properties, and applicable working conditions. Proper material selection is a key factor in extending wheel service life and ensuring operational safety.

|

Wheel Material |

Manufacturing Process |

Main Performance Characteristics |

Wear Resistance |

Strength & Toughness |

Service Life |

Applicable Working Conditions |

|

Cast steel wheel |

Casting | Lower cost, good overall structural integrity, stable performance | Average | Medium | Shorter | Light or medium loads, low duty class, overhead crane applications with low operating frequency |

|

Forged steel wheel |

Forging | Dense structure, good impact resistance and fatigue strength | Good | High | Longer | Medium loads, high-frequency operation, frequent start/stop overhead cranes |

|

Alloy steel wheel |

Alloy steel + heat treatment | Very high strength, excellent wear resistance and fatigue performance | Excellent | Very high | Long | Heavy loads, high duty class, continuous operation, or harsh environments |

Overall performance considerations:

▴Cast steel wheels are more suitable for cost-sensitive applications with relatively mild operating conditions.

▴Forged steel wheels achieve a good balance between strength and wear resistance, making them widely applicable.

▴Alloy steel wheels deliver the best performance in terms of wear resistance, load capacity, and service life, and are ideal for high-end and demanding applications.

In practical selection, lifting capacity, duty class, operating frequency, and environmental conditions should be evaluated together to choose the most suitable wheel material, achieving an optimal balance between performance and cost.

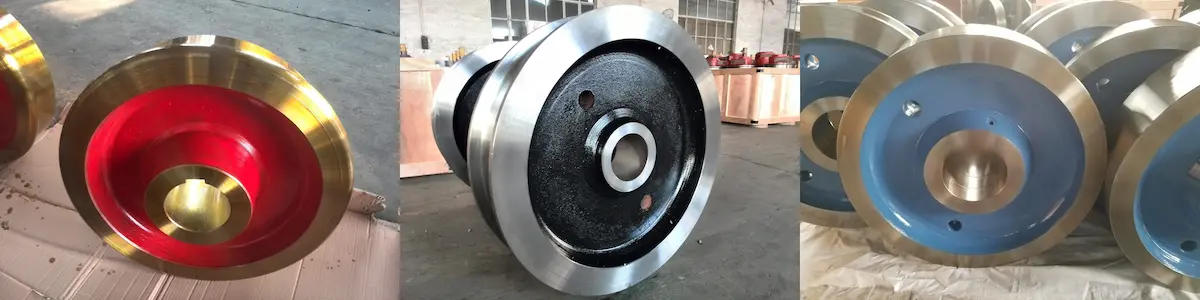

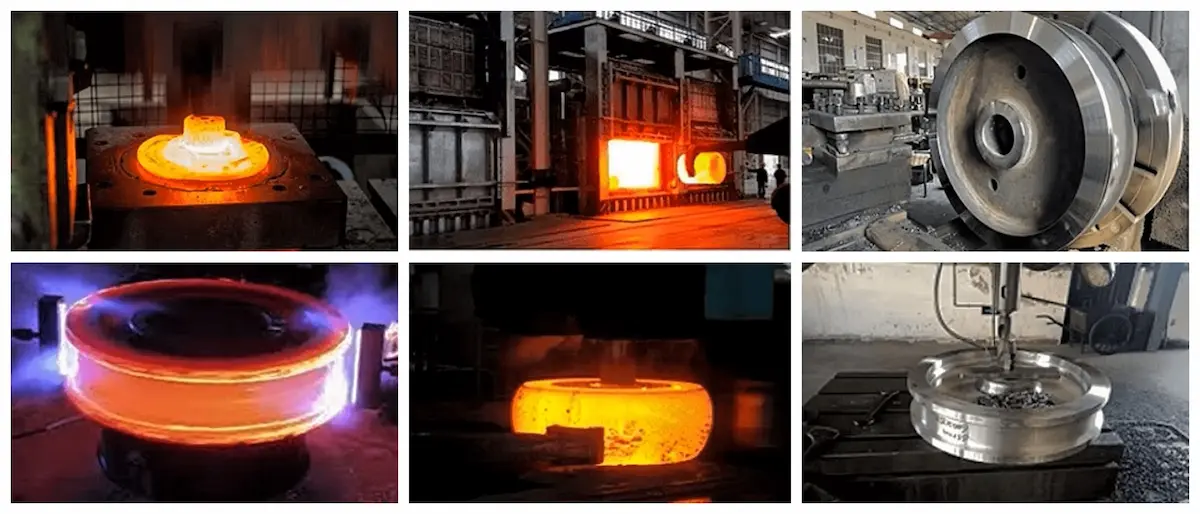

(Taking the manufacturing process of HSCRANE forged steel wheels as an example)

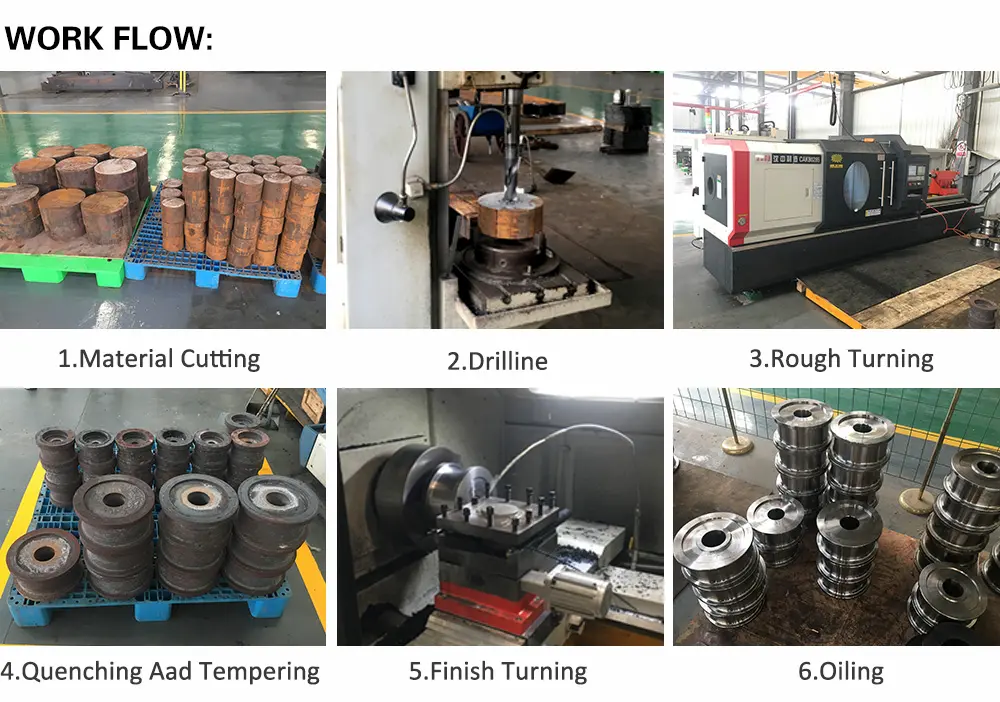

Manufacturing Process of Crane Wheels

The quality of crane wheels directly determines the operational safety and service life of an overhead crane. HSCRANE wheels are manufactured using a scientifically designed process, which mainly includes the following key stages:

Material Cutting

▴High-quality steel materials that meet applicable standards are selected to ensure reliable raw material quality.

▴Precise cutting according to design dimensions provides a solid foundation for subsequent machining.

Drilline

▴Machining of the hub center bore and mounting holes to ensure accurate matching between the wheel and the axle or crane structure.

▴Strict control of concentricity improves assembly accuracy and ensures smooth operation.

Rough Turning

▴Initial forming of the flange, tread, and hub to establish the basic wheel geometry.

▴Machining allowances are reserved for subsequent heat treatment to avoid deformation affecting accuracy.

Quenching Aad Tempering

▴Quenching increases surface hardness and enhances wear resistance.

▴Tempering ensures internal toughness, prevents brittleness or cracking, and improves overall reliability.

Finish Turning

▴Precision machining of the tread and flange to ensure dimensional accuracy and surface quality.

▴Ensures good contact between the wheel and the rail, reducing rail gnawing and vibration.

Lubrication and Protective Treatment(Oiling)

▴Lubrication of critical areas reduces friction and wear.

▴Surface anti-rust and anti-corrosion treatments enable adaptation to complex operating environments and extend service life.

Through optimized material selection and a controlled manufacturing process, crane wheels can achieve stable performance and long-term reliability, supporting safe and efficient operation of overhead cranes.

Advantages of HSCRANE Crane Wheels

Strict raw material control and mature manufacturing processes: HSCRANE crane wheels are manufactured from high-strength alloy steel or premium forged steel. Chemical composition and internal microstructure are strictly controlled. Through proven forging, heat treatment, and precision machining processes, each wheel achieves stable mechanical properties and consistent product quality.

Customized wheel solutions based on actual operating conditions: According to different lifting capacities, operating frequencies, rail types, and environmental conditions, HSCRANE provides customized wheel designs. Options include wheel diameter, flange configuration, tread hardness, and bearing arrangements, ensuring a high level of compatibility with the customer’s real working conditions.

High wear resistance: By optimizing heat treatment processes and tread hardness distribution, HSCRANE crane wheels maintain excellent wear resistance even under high loads and high-frequency operation. This effectively reduces tread wear and replacement frequency, significantly lowering total lifecycle maintenance costs.

High compatibility with the crane and rail system: Wheel design fully considers coordination with the crane structure, wheel load distribution, and rail parameters from the initial stage. This ensures smooth operation and balanced load transfer, minimizes impact on rails and the crane structure, and enhances overall system reliability.

Extensive international project experience: HSCRANE crane wheels have been widely applied in international heavy-duty projects across industries such as steel, metallurgy, ports, and power generation. With proven performance under high loads, high duty cycles, and complex operating conditions, they provide reliable support for export and high-standard projects.

Common Misconceptions in Crane Wheel Selection and Recommended Solutions

Focusing only on price while ignoring operating conditions

Misconception: Selecting crane wheels based solely on purchase price, while neglecting key factors such as lifting capacity, duty class, operating frequency, and environmental conditions, can result in insufficient material strength or structural design. This often leads to abnormal wear, fatigue cracks, or even premature failure during operation.

Recommendation: Wheel selection should be based on a comprehensive evaluation of actual operating conditions, including rated wheel load, duty class, usage frequency, and environment. Choosing materials and heat treatment solutions that match real working conditions ensures long-term stable operation rather than simply minimizing initial cost.

Ignoring the compatibility between wheel load and rail system

Misconception: Some selections focus only on the load capacity of individual wheels while overlooking the matching between tread profile, flange structure, rail type, gauge, and installation accuracy. This may cause excessive local contact stress, accelerated rail wear, rail gnawing, or unstable crane travel.

Recommendation: Wheel load distribution and rail parameters should be verified simultaneously during the selection stage. Proper matching of rail type and tread profile, combined with structural load analysis of the entire crane system, helps ensure coordinated operation and reduces resistance and structural damage risks.

Neglecting long-term maintenance costs

Misconception: Focusing only on initial procurement cost while ignoring long-term wear rate, replacement intervals, and downtime maintenance costs can lead to frequent wheel replacements and increased downtime, ultimately raising overall operating expenses.

Recommendation: Wheel selection should be evaluated from a full lifecycle perspective. Prioritize solutions with high wear resistance, stable performance, and long maintenance intervals to reduce replacement frequency and maintenance intensity, achieving lower total cost of ownership and higher equipment availability.

Proper crane wheel selection is a fundamental requirement for ensuring the safe, stable, and efficient operation of an overhead crane. As a critical component of the load-bearing and travel system, crane wheels directly affect wheel load distribution, traveling stability, rail service life, maintenance costs, and long-term reliability. Ignoring differences in operating conditions, system compatibility, or lifecycle cost considerations often leads to frequent failures, downtime losses, and even safety risks during operation.

Therefore, when selecting an overhead crane and its key components, choosing a manufacturer with extensive experience, mature technology, and strong system design capability is essential. With years of crane manufacturing expertise and extensive international project experience, HSCRANE provides reliable, durable, and highly matched crane wheel solutions for overhead cranes operating under various conditions—helping customers achieve a balance between operational safety and long-term value.

Contact HSCRANE to receive professional selection guidance and customized crane wheel solutions, and choose truly suitable and reliable crane wheels for your overhead crane.

Want to further understand the key components that ensure overall overhead crane traveling stability?

Click to learn about HSCRANE end carriage solutions:

Everything You Need to Know About Crane End Carriages — comprehensively improving equipment safety and operational reliability.