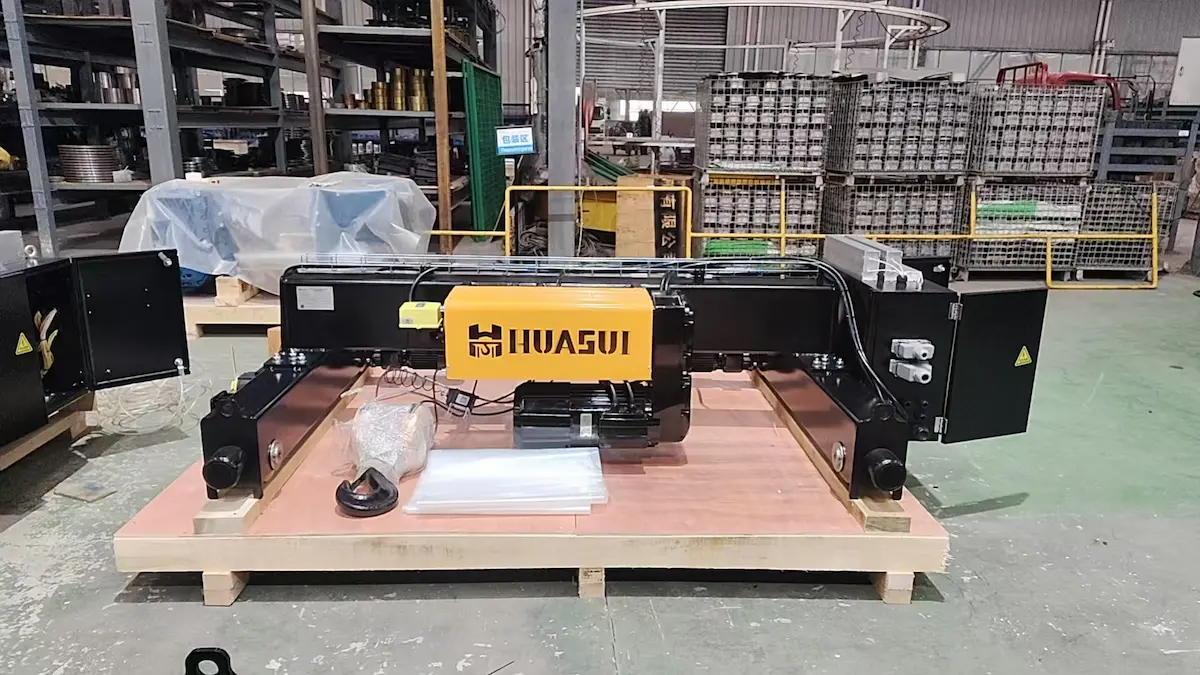

Recently, twelve FEM standard hoists customized by HSCRANE for a UAE client were successfully manufactured, inspected, packaged, and shipped to site. This delivery demonstrated HSCRANE’s mature manufacturing capability in European lifting equipment and validated strong Middle East project execution expertise.

Customer Requirements and Project Challenges

The UAE customer mainly serves local industrial and infrastructure construction sectors and requires high operational stability, compact structure, and safety performance. Considering limited site space, high duty frequency, and elevated ambient temperatures, the customer selected FEM standard hoist solutions for efficient and stable long term operation.

Meanwhile, the project required a strict delivery schedule, with all units produced and shipped together on time. This posed challenges for production planning, quality control, and supply chain coordination.

Customized Solution Design

Based on actual UAE site conditions and operational requirements, HSCRANE engineers customized twelve FEM standard hoists. During design, key parameters were systematically configured to balance performance, safety, and maintenance needs, as follows:

Lifting capacity: Customized according to project requirements, covering the specified rated loads

Hoisting mechanism: European low headroom design, compact structure, improving building space utilization

Hoisting speed: Single or dual speed options, meeting precise lifting requirements under different conditions

Travel speed: Smooth and adjustable, ensuring safety and stability during heavy load operation

Duty class: Designed to match usage frequency, suitable for medium to high intensity operations

Motor configuration: High performance motors, adapted to UAE high temperature environments

Control mode: Pendant or remote control options, enhancing operational flexibility and safety

Protection class: Key components provide reliable protection, suitable for Middle East conditions

Maintenance design: Modular structure, enabling easy inspection and component replacement

System compatibility: Seamlessly matches European overhead crane systems for integrated solutions

Through optimized parameter configuration, HSCRANE delivered a FEM standard hoist solution balancing performance, reliability, and long term value.

Strict Manufacturing and Quality Control

During production, HSCRANE strictly implemented standardized manufacturing procedures. From raw material inspection to component machining, assembly, and commissioning, every stage was tracked and documented by quality inspectors.

Before shipment, all twelve FEM standard hoists completed no load and rated load testing. Hoisting, traveling, and braking performances fully met design requirements, ensuring safety and reliability.

Project Significance and Market Value

The successful delivery of this FEM standard hoist project further strengthened HSCRANE’s brand influence in the Middle East market. With stable product performance, reliable delivery capability, and professional execution experience, HSCRANE continues earning overseas customer trust.