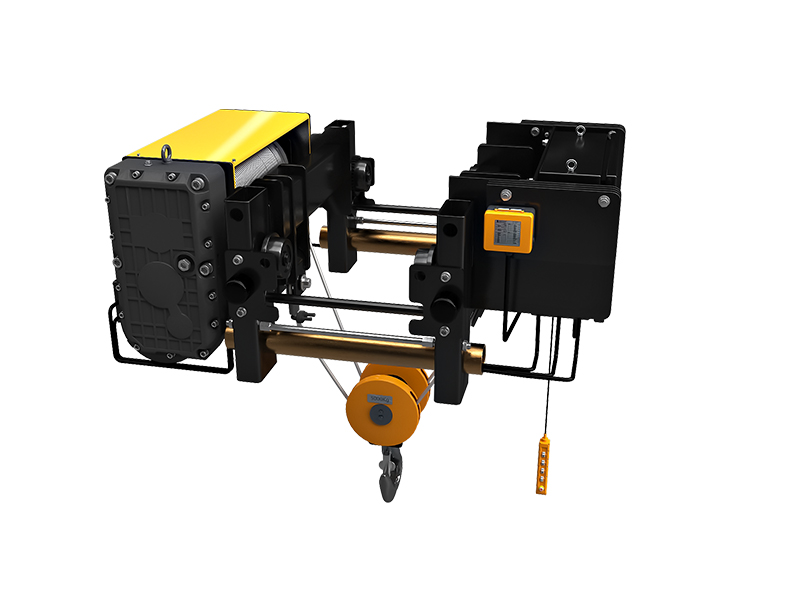

HSCRANE European-style electric wire rope hoists are designed according to European FEM standards. Compared with traditional hoists, they offer a more refined appearance, easier operation, and advanced design. They also meet modern requirements for low noise, energy efficiency, and environmental protection.

Key Parameters

| Parameter | Specification |

|---|---|

| Standard | FEM, DIN |

| Lifting Capacity | 0.5 – 50 t |

| Lifting Height | 6 – 30 m |

| Duty Class | M5 – M7 |

| Operating Temperature | -20 ℃ – 40 ℃ |

| Relative Humidity | ≤ 85% |

| Control Method | Pendant controller / Remote control |

| Power Supply | 380 V / 3-phase / 50 Hz orlocal industrial voltage |

Main Features

-

Compact Structure: Lightweight design, small size, low wheel load.

-

Advanced Welding Technology: Higher rigidity, lower energy loss.

-

Minimal Blind Spots: Wider working range.

-

Green and Energy-Efficient: Reduces energy consumption, increases efficiency.

-

European FEM Standards: User-friendly lifting and trolley speed parameters.

Operating Speeds:

-

Trolley Travel Speed: 0.5–20 m/min

-

Crane Travel Speed: 10–40 m/min (variable frequency adjustable)

Comparison with Traditional Hoists

| Feature | Traditional Hoist | European Hoist |

|---|---|---|

| Structural Design | Separate motor and gearbox, large size | Integrated motor and gearbox, 30%-50% smaller |

| Transmission | Ordinary gears, efficiency ≤ 85% | Hardened helical gears, efficiency ≥ 96% |

| Lifting Motor | Three-phase asynchronous motor, high starting current | Permanent magnet synchronous / frequency conversion motor, saves 25%-40% energy |

European-style hoists provide higher performance, precision, and energy efficiency, making them ideal for enterprises seeking reliable lifting solutions.

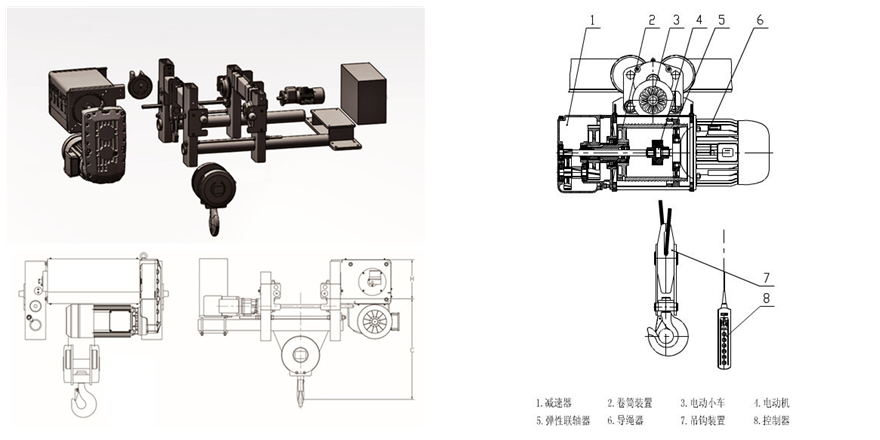

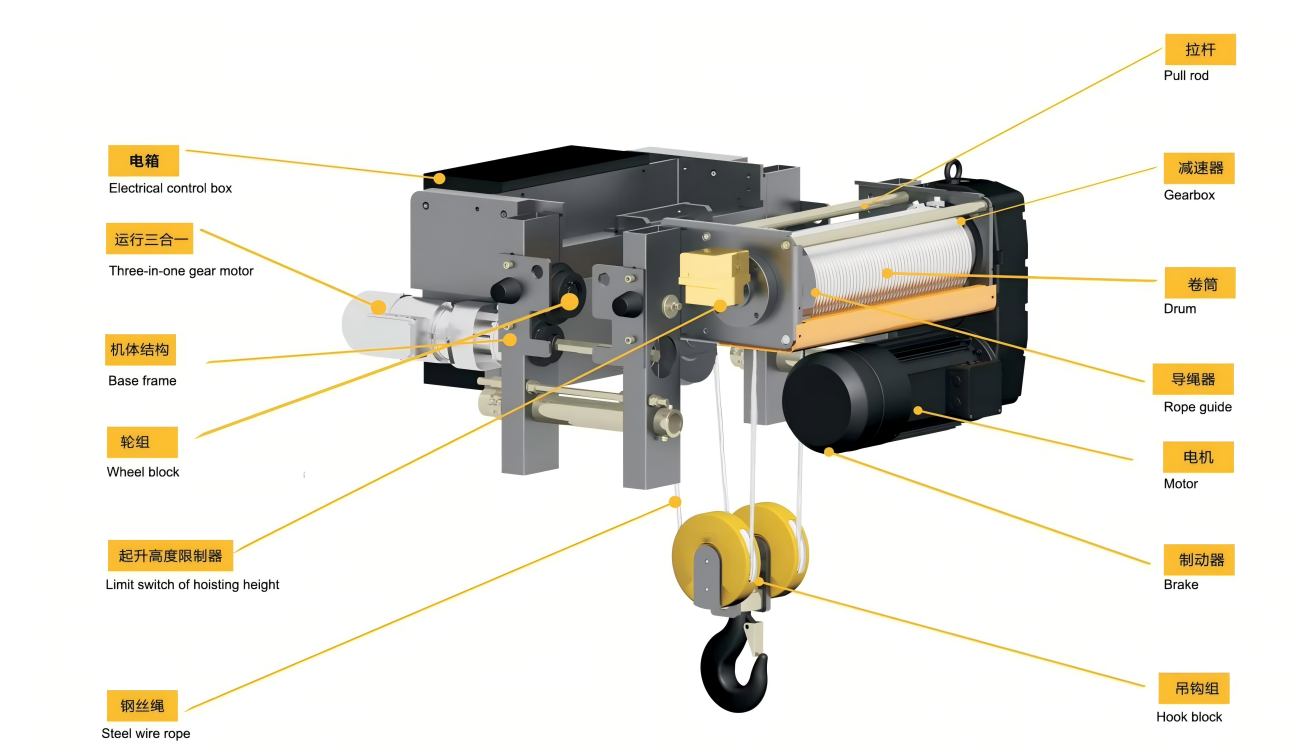

Components of European-Style Hoists

1. Hoisting Drive Unit

-

Integrated design: gearbox, motor, brake.

-

High lifting torque, smooth operation, low impact.

-

Quiet, energy-efficient, durable.

-

60% duty cycle, ideal for frequent lifting.

2. Trolley Drive Unit

-

Compact, integrated, smooth operation.

-

Aluminum alloy housing for heat dissipation.

-

VFD control for quiet operation.

-

Soft start, precise braking, asbestos-free brake disc.

3. Sheaves

-

High-strength seamless steel, FEM-standard groove depth.

-

Secure rope termination for safe lifting.

4. Electrical Cabinet

-

Optimized for maintenance and inspection.

-

Multiple safety devices, clear wiring.

5. Wire Rope Guide & 6. High-Performance Wire Rope

-

Lightweight, wear-resistant, protects the rope.

-

Imported high-strength steel, galvanized, durable, flexible.

7. Lifting Hook

-

Safety latch and wire rope sleeve.

-

T-class forged steel hook, high load capacity.

Applications

| Scenario | Load | Features | Benefits |

|---|---|---|---|

| Manufacturing | 5–20 t | Dual-speed VFD, RFID positioning | Faster deployment, mold change time reduced 40% |

| Warehousing & Logistics | 1–10 t | Low-headroom design, WMS integration | Lifting height increased 40% |

| Ports & Shipyards | 10–50 t | Anti-salt spray coating, weather-resistant rope | Wind-resistant, longer corrosion protection |

| Metallurgy & Energy | 32–100 t | Explosion-proof, high-temperature rope | 24/7 operation, 1.5× overload protection |

| Precision Equipment | 0.5–5 t | Micro-speed control, laser rangefinder | Minimal vibration for delicate equipment |

Future Market Prospects

With IoT, AI, and 5G integration, European electric hoists can upload real-time data for monitoring. They support self-diagnosis and predictive maintenance, preventing industrial risks. PLC programming enables unmanned material handling, improving efficiency and reducing labor costs. Companies with strong R&D and global service networks will dominate, while traditional low-cost hoists gradually exit.

How to Choose the Right European Hoist

1. Usage Requirements

-

Rated lifting capacity with 10%-20% safety margin.

-

Determine lifting height and speed.

2. Working Environment

-

Temperature: -20℃ to 40℃, customizable for extreme conditions.

-

Special scenarios: explosion-proof, dust-proof, humid, corrosive.

3. Operation Mode

-

Installation: fixed or mobile.

-

Control: pendant, remote, or integrated console.

Conclusion

HSCRANE European-style electric wire rope hoists combine advanced design, high performance, and energy efficiency. They are ideal for a wide range of industrial applications, including manufacturing, logistics, ports, metallurgy, and precision equipment handling. By choosing HSCRANE hoists, enterprises can improve operational efficiency, ensure safe lifting, and reduce energy costs. With continuous innovation and reliable service, HSCRANE is committed to providing the best lifting solutions for global industries.