In bridge crane material handling, the grab performs the most direct and critical loading function. Its type and performance often determine overall efficiency and stability. Different grab types vary in gripping methods, power sources, and structural features. These differences affect efficiency, energy use, maintenance difficulty, and service life.

In real operations, industries handle very different materials. From light bulk, ore, scrap, waste, to timber, each material requires specific grab force and precision. Selecting a grab that matches the working conditions is essential. It improves capacity, reduces cost, and ensures long-term reliability.

What Is a Mechanical Grab? Working Principles and Applications

Definition and Structural Features of Mechanical Grabs

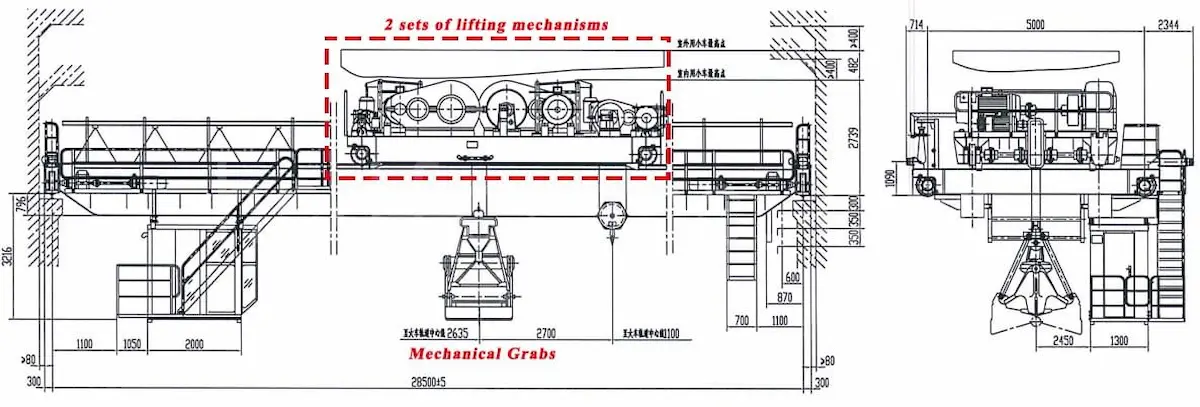

- Definition: A mechanical grab uses wire ropes or winches to open and close. It works with bridge cranes, gantry cranes, or port equipment.

- Core structure: It includes two or more shells, pulley sets, opening mechanisms, and rope systems. Its simple, robust design offers high reliability.

- Structural traits: Its simple structure and strong durability reduce daily maintenance cost. It is suitable for continuous, high-frequency operations.

- Working principle: The grab uses wire ropes as the main power source. Lifting and closing ropes control opening and closing actions. When lowered into bulk material, the closing rope tightens and the shells grip the load.

Advantages of Mechanical Grabs

Mechanical grabs have dominated industrial handling for many years. Their advantages include the following:

- Lower cost: They require no hydraulic or electrical systems. Manufacturing and operating costs are much lower than hydraulic grabs.

- High compatibility: They work with most wire-rope bridge cranes. They do not depend on hydraulic interfaces and fit many industrial sites.

- Ideal for long-term duty: Their simple structure offers low failure rates. They maintain stable performance in continuous, high-cycle operations.

Common Application Scenarios

- Bulk materials (coal, sand, ore): Mechanical grabs perform well with dense, free-flowing materials. They are widely used in coal yards, ore terminals, and aggregate plants.

- High-frequency loading systems: They support continuous, heavy-volume operations. Ports and bulk transfer sites rely on their efficiency and easy maintenance.

- Cranes without hydraulic systems: Mechanical grabs need only wire-rope power. They suit traditional wire-rope bridge and gantry cranes without extra hydraulic interfaces.

What Is a Hydraulic Grab? Working Principle and Applications

Structure and Power System of Hydraulic Grabs

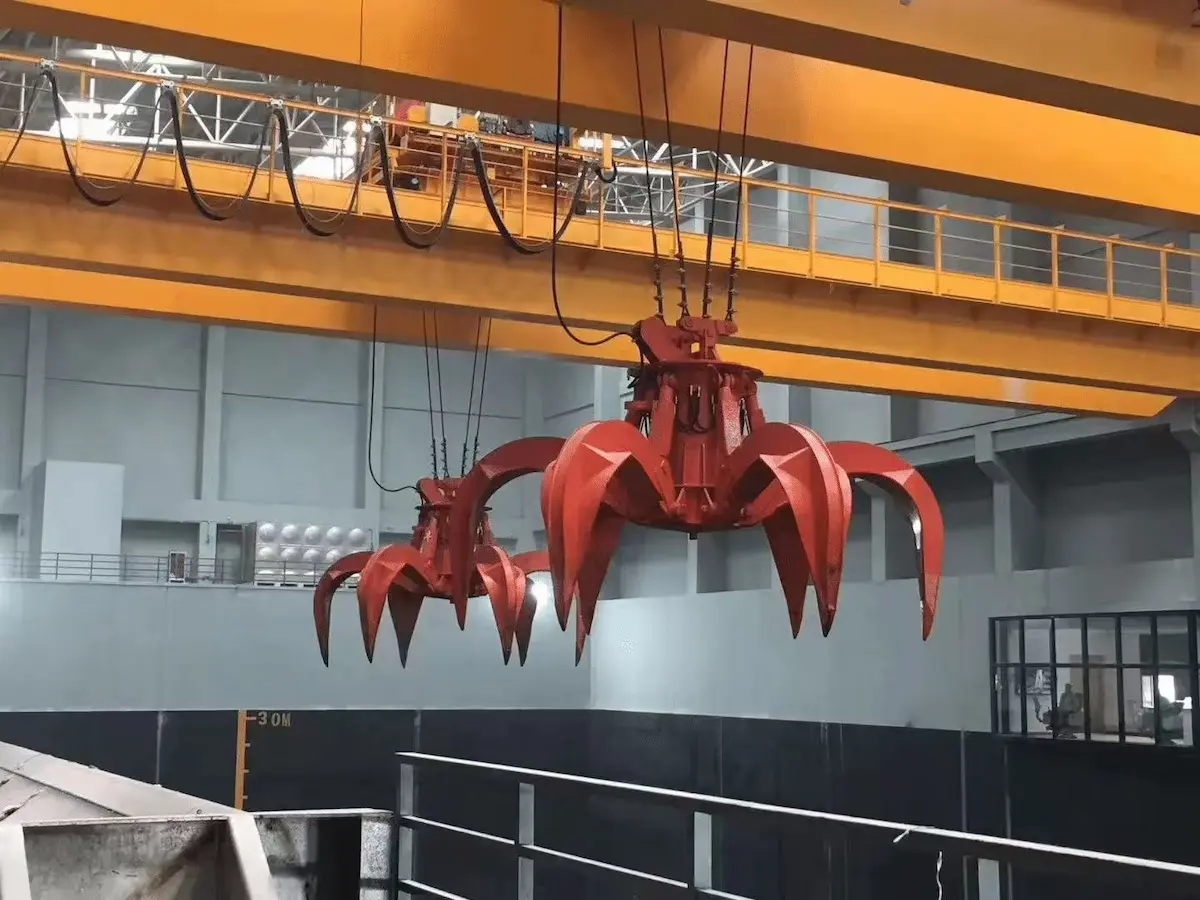

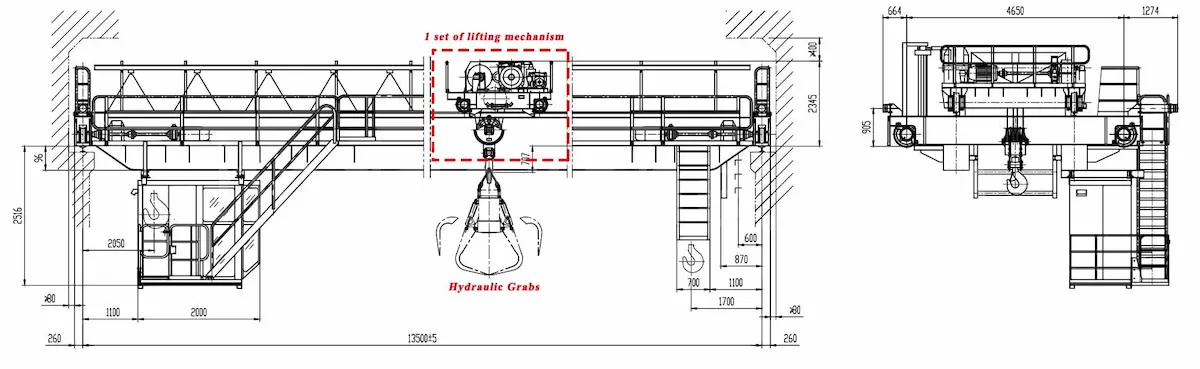

- Definition: A hydraulic grab uses a hydraulic system to drive opening and closing. It relies on hydraulic cylinders for strong gripping force and precise motion control.

- Core structure: It may use a built-in hydraulic pump or an external power pack. An electric control system ensures fast response to commands. It includes cylinders, valve groups, shell mechanisms, frames, and control units.

- Structural traits: The hydraulic system offers flexible control and precise adjustment. It provides clear advantages in demanding industrial environments.

- Power system: High-pressure oil drives cylinder extension and retraction. This motion opens or closes the shells. Hydraulic drive delivers smoother and stronger gripping force than wire-rope systems. It performs well with heavy, irregular, or uneven-density materials.

Advantages of Hydraulic Grabs

Hydraulic grabs are widely used in scrap, waste, and timber handling. Their advantages include the following:

- Stronger gripping force: The hydraulic system provides much higher clamping force. It suits dense, heavy, or block-shaped materials such as scrap or construction waste.

- High control precision: Electric or remote control enables fine cylinder movement. The grab achieves precise opening, speed control, and gripping angles. This improves efficiency and safety.

- Better handling of irregular materials: Hydraulic shells apply uniform force and flexible motion. They fit complex shapes such as waste, timber, and mixed materials. They excel in uneven or irregular working conditions.

Common Application Scenarios

- Waste-to-energy plants: Used for household waste and mixed solid waste. It ensures stable feeding to the incinerator.

- Scrap handling: Strong clamping force suits scrap steel, metal blocks, and vehicle parts. It withstands heavy loads and high-impact conditions.

- Timber and recycling industries: Suitable for timber, roots, and irregular waste materials.

- Tasks requiring complex motions: Sorting, batch feeding, and precise stacking benefit from hydraulic motion control.

Mechanical Grab vs. Hydraulic Grab: Key Differences

|

Item |

Mechanical Grab |

Hydraulic Grab |

| Power source | Driven by wire ropes or winches; no hydraulic system needed | Cylinders driven by built-in or external hydraulic units |

| Complexity | Simple structure with low failure rate | Complex system with cylinders, valves, pumps, and controls |

| Gripping force | Medium; suited for bulk and free-flowing materials | Strong; ideal for heavy, dense, or irregular materials |

| Control precision | Basic actions; affected by rope positions | High precision with fine adjustment and accurate positioning |

| Motion flexibility | Limited; unsuitable for complex operations | Flexible; supports multi-axis control and precise feeding |

| Material types | Coal, sand, ore, grain, chemical bulk | Scrap, waste, timber, construction debris, irregular items |

| Industries | Ports, mines, aggregate plants, bulk storage | Waste plants, scrap yards, timber mills, recycling sites |

| Initial cost | Low and budget-friendly | Higher; requires hydraulic system or power pack |

| Energy use | Lower; depends on crane power | Higher; hydraulic system needs extra energy |

| Maintenance | Simple; mainly ropes and mechanical wear | More complex; requires oil, seals, valves, and cylinder checks |

| Reliability | Durable and stable for continuous duty | High performance but more dependent on maintenance |

| Environmental tolerance | Strong dust and wind resistance for outdoor work | Needs better protection in harsh environments |

| Crane requirements | Compatible with wire-rope bridge cranes; no extra interfaces | Requires hydraulic or electrical interfaces or added power packs |

| Productivity | High cycle speed for bulk handling | Better for complex materials with stable gripping |

How to Choose the Best Grab for Your Overhead Crane?

Selecting the right grab requires evaluating material traits, budget, efficiency, and maintenance capacity. Mechanical and hydraulic grabs offer clear advantages. Selection can follow four key decision factors.

|

Decision Factor |

Selection Condition |

Recommended Type |

Explanation |

| Material type | Bulk materials like coal, sand, ore, and granules |

Mechanical grab |

Bulk material flows well, and mechanical grabs offer high efficiency and lower cost |

| Heavy or irregular materials like scrap, timber, waste, and mixed debris |

Hydraulic grab |

Hydraulic grabs offer strong force and fit complex shapes with higher stability | |

| Budget | Limited budget and low initial investment |

Mechanical grab |

No hydraulic system required; cost and maintenance are lower |

| Need higher efficiency and precise control |

Hydraulic grab |

Higher cost but better return; ideal for high-value operations | |

| Maintenance capability | Limited team with general maintenance skills |

Mechanical grab |

Simple structure and low failure rate; no hydraulic expertise required |

| Professional engineering team available |

Hydraulic grab |

Ensures long-term performance of hydraulic and control systems | |

| Operating scenario | High-frequency bulk handling and continuous duty |

Mechanical grab |

Short cycles and strong durability for heavy repetitive work |

| Tasks requiring complex control actions |

Hydraulic grab |

High controllability enables fine and adjustable grabbing motions |

HSCRANE Customization Capabilities for Overhead Crane Grabs

- Custom mechanical grab designs: HSCRANE provides custom single-rope, dual-rope, and four-rope mechanical grabs. Designs match material types, capacity demand, and onsite conditions. They suit bulk storage, ore yards, and aggregate terminals with high durability, easy operation, and low maintenance.

- Hydraulic grab control and motion optimization: HSCRANE offers high-performance hydraulic systems with custom control options. Precise cylinder control improves gripping force and motion speed. Hydraulic grabs handle scrap, waste, timber, and irregular loads with higher accuracy and efficiency.

- High compatibility design: HSCRANE grabs fit bridge cranes, port cranes, and waste-handling cranes. They run reliably on new crane systems or upgraded existing cranes. Custom matching solutions ensure efficient coordination between cranes and grabs.

- Installation, commissioning, and lifetime support: HSCRANE provides professional installation and commissioning services. Lifetime technical support includes remote guidance, maintenance advice, and spare parts. This ensures safe, stable grab operation and reduces downtime.

Mechanical grabs offer simple structure, durability, and low cost. They suit bulk materials and high-frequency loading. Hydraulic grabs provide strong force and high precision. They suit heavy, irregular materials and complex motion tasks. Choosing the right grab improves crane efficiency and safety.

Want to know which grab suits your crane? Contact HSCRANE for professional grab selection support and ensure stable crane performance.

You may also like: Crane Hooks: Types, Applications, and Safety Standards in Industrial Lifting, assisting in the efficient coordinated operation of the grab bucket and lifting system.