During the operation of an overhead crane, the brake is a critical component that ensures equipment safety and precise control. Whether lifting loads, traveling the crane, or performing accurate positioning, the brake plays an essential role in rapid braking, reliable holding, and emergency stopping. When the crane loses power or encounters unexpected failures, the brake serves as the final safety barrier that protects both equipment and personnel.

The brake works in close coordination with the crane’s hoisting and traveling mechanisms. By delivering precise braking torque, it enables the overhead crane to maintain stable performance under demanding working conditions. A high-quality braking system not only improves operational efficiency but also directly affects the crane’s lifespan and safety rating. Therefore, selecting the right brake for different application environments is vital and irreplaceable for safe and efficient industrial operations.

Main Types and Features of Brakes Used in Overhead Cranes

Overhead cranes require different braking performance depending on the working conditions, leading to the development of multiple brake types with different structures and operating principles. Below are the most common brake types used in crane applications and their characteristics:

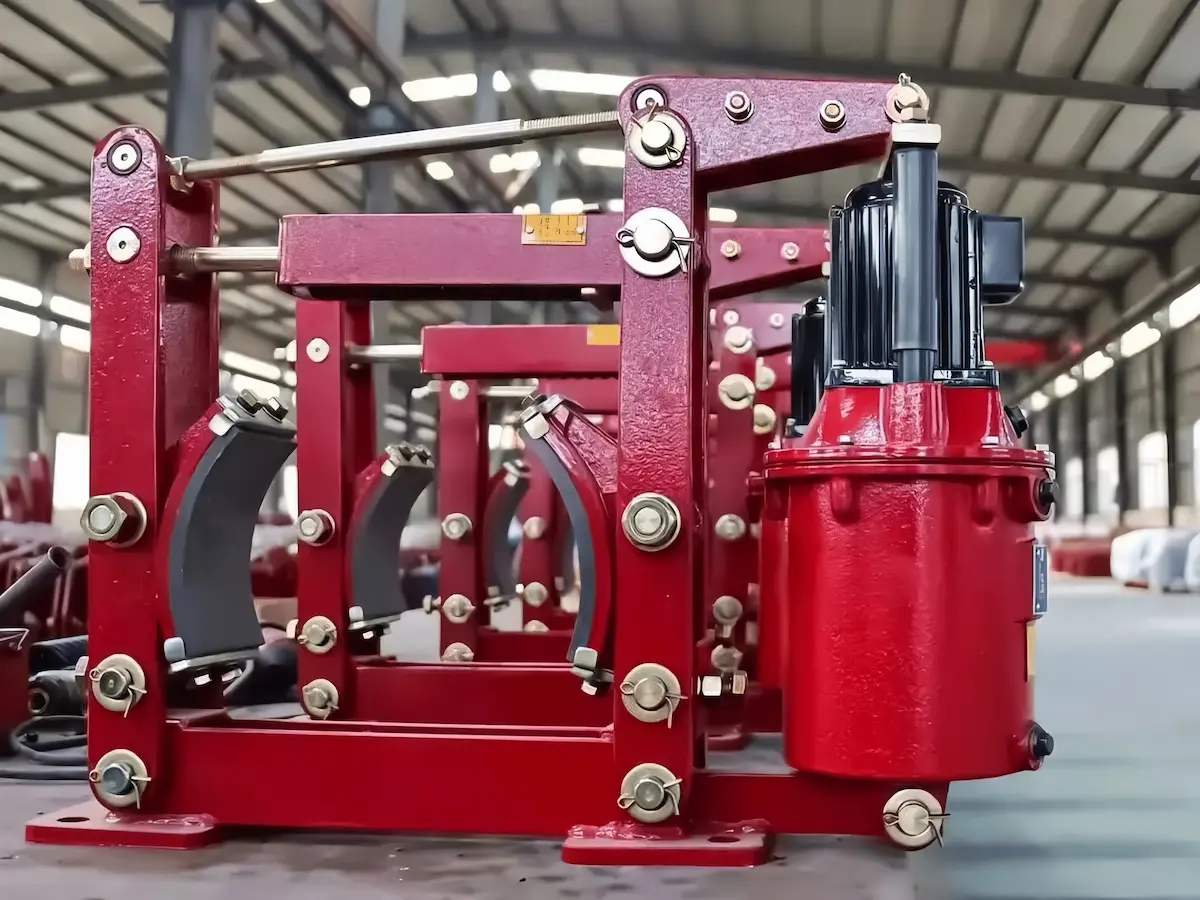

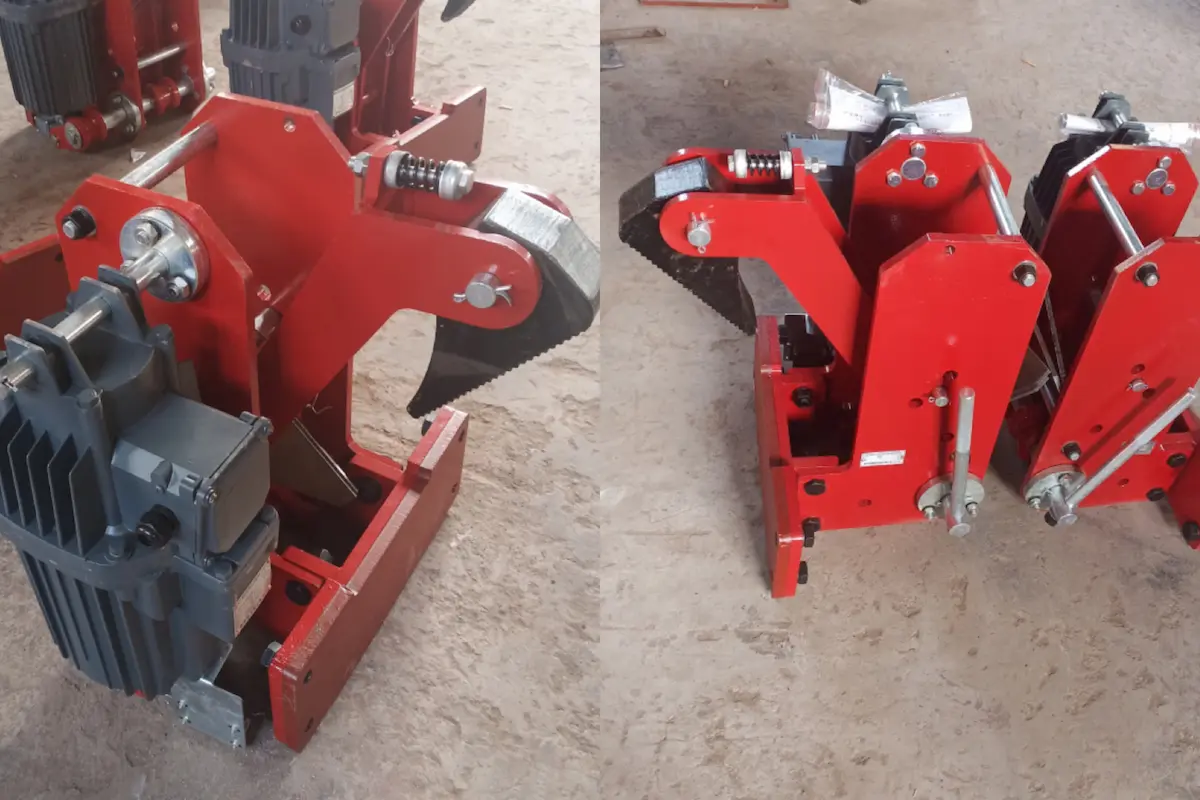

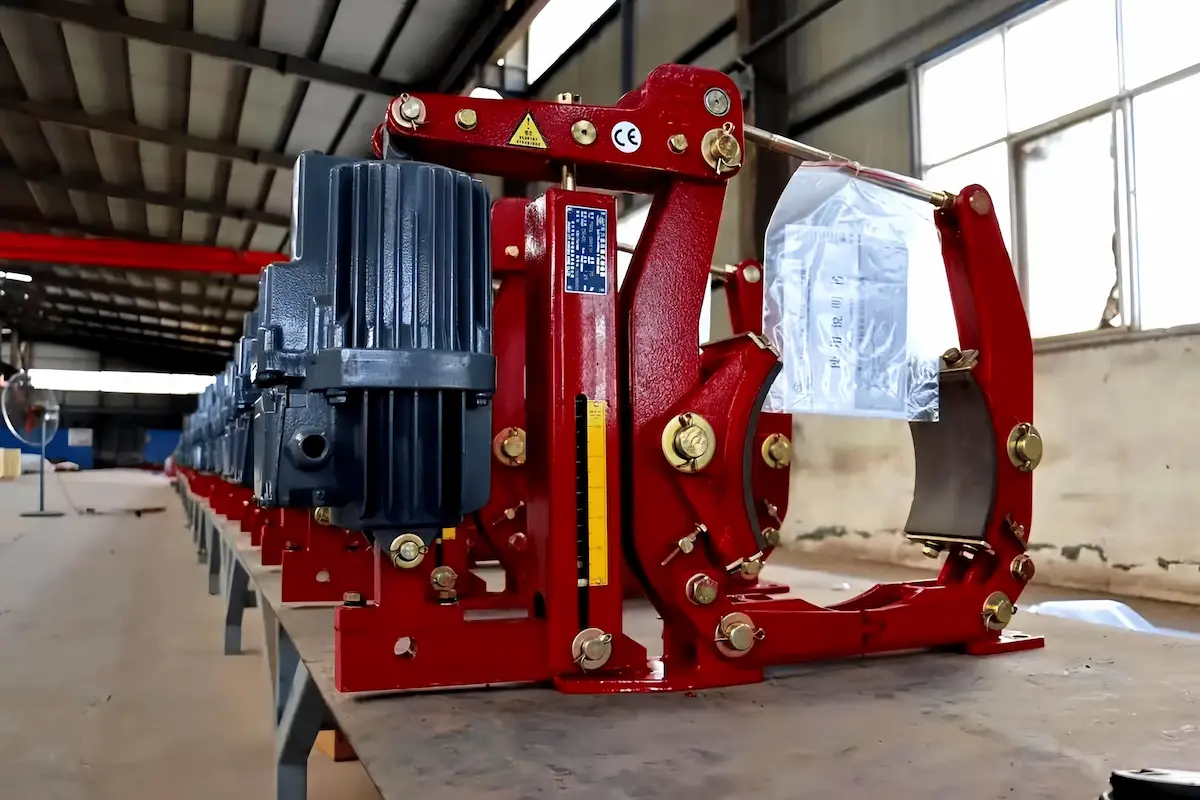

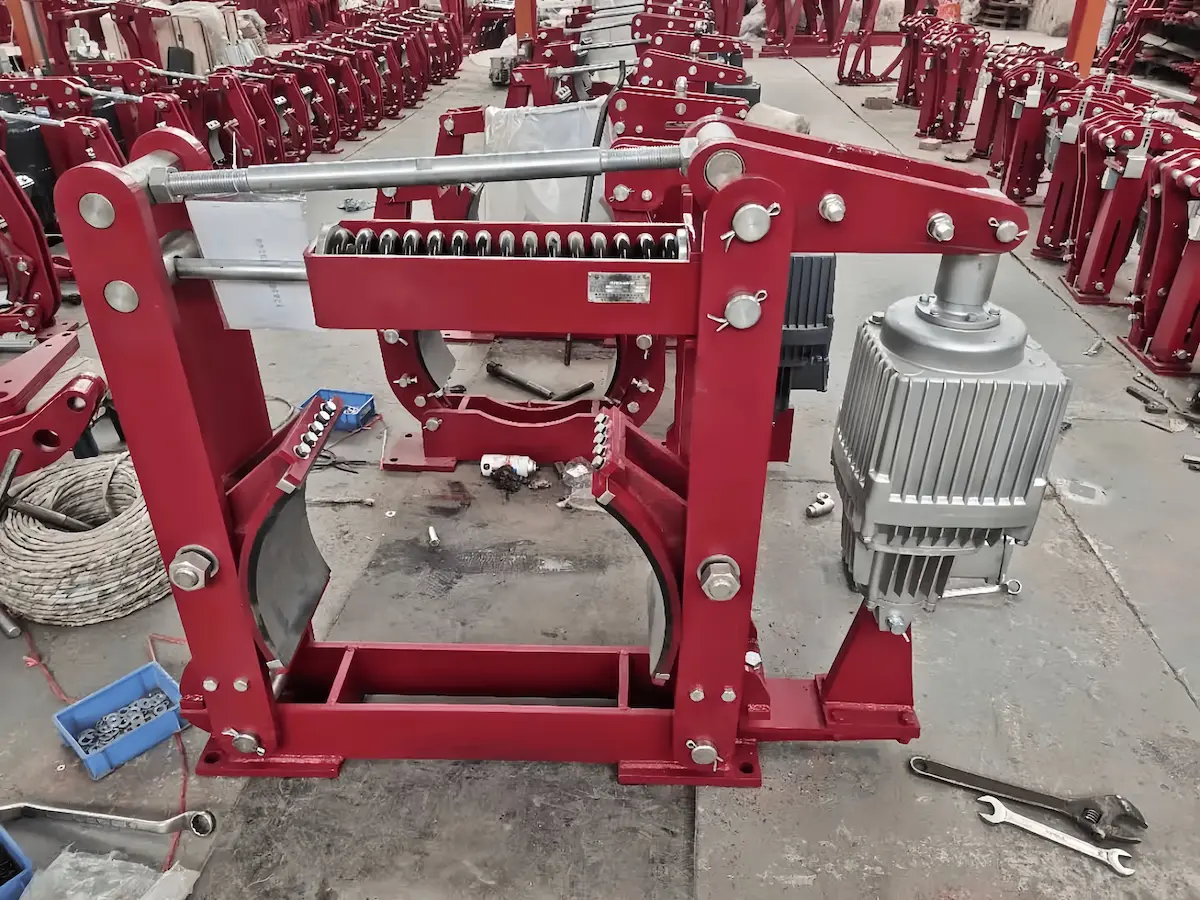

Drum Brake

Structure: A drum brake consists of a brake wheel, brake shoes, springs, electromagnets, and lever mechanisms. It uses friction to transmit braking torque and is one of the most widely used brake systems in industrial cranes.

Working Principle: When released, springs or electromagnets retract the brake shoes away from the drum, allowing free rotation. When activated, the electromagnet or hydraulic actuator pushes the brake shoes against the inner surface of the drum, generating friction to stop or slow rotation.

Features:

Mature and highly stable design

Easy maintenance, simple spare-part replacement

Cost-effective with high value

Supports multi-level braking torque configurations

Applications: Commonly used in general overhead cranes, medium- and small-tonnage lifting equipment, and workshop material-handling systems—considered a standard braking solution in the industry.

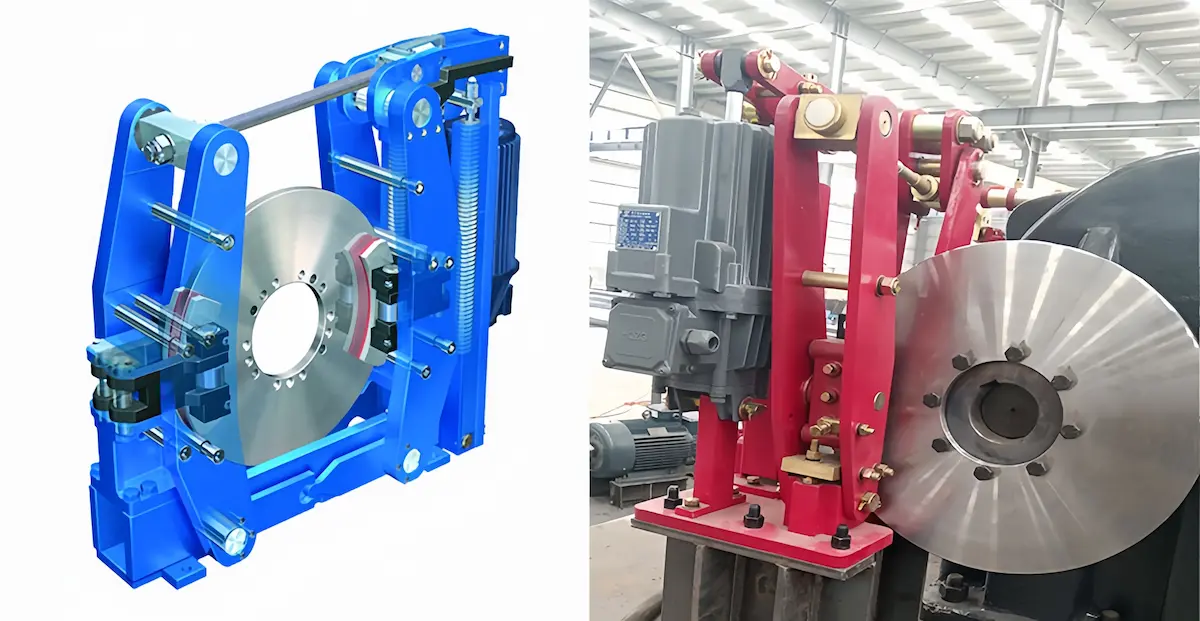

Disc Brake

Structure: A disc brake includes a brake disc, calipers, and a driving unit (hydraulic or electromagnetic), generating braking force by clamping the disc.

Technical Advantages:

Strong braking force for fast stopping and heavy-load braking

Excellent heat dissipation for long-term operation without performance loss

Fast response and high braking sensitivity

Can be installed on high-speed shafts, reducing required braking torque

Typical Applications: High-speed cranes, heavy-duty metallurgy cranes, high-duty-cycle production lines, and any environment requiring exceptional braking performance and safety.

Wind-proof Brake

Primary Purpose: Designed to resist wind loads and prevent the crane from moving along the rail or overturning, ensuring safety in outdoor environments.

Common Types:

Rail clamps: lock the crane onto the rail

Wheel-side brakes: restrict wheel movement

Anti-wind wedge systems: provide additional lateral stability

Applications: Used in port cranes, coastal operations, outdoor gantry cranes, and other wind-exposed environments.

Safety Brake System

These systems serve as redundancy and emergency protection components in addition to the main brake. Typical configurations include:

Dual-brake systems

Fail-safe braking (automatic braking upon power loss)

Integration with limit switches and emergency stop systems

Core Purpose: To keep the equipment safely stopped even when the main brake fails or power is lost, preventing slipping, dropping, or other hazardous events.

Working Principle of Overhead Crane Brakes

Friction braking mechanism: The brake generates friction by pressing brake shoes or friction pads against a brake drum or disc, converting mechanical energy into heat and producing braking torque to decelerate or stop moving components. Factors such as friction coefficient, contact area, and material heat resistance determine the stability and reliability of braking performance.

Relationship between braking torque, load, and speed: Higher loads or faster speeds require greater braking torque. Brakes must be designed according to the maximum dynamic load of the hoisting and traveling mechanisms to ensure safe stopping in emergency conditions.

Safety brake structure: Most overhead crane brakes adopt a “fail-safe, power-to-release” design, where springs automatically apply braking force in case of power failure, malfunction, or emergency. During normal operation, electromagnetic or hydraulic devices release the brake.

Control response and system interlocks: Brakes must respond quickly and coordinate with variable frequency drives, controllers, and other control systems to ensure smooth, impact-free starting and stopping.

Application Scenarios and Selection Guide for Overhead Crane Brakes

Brake selection depends on working environment, rated load, travel speed, and operating frequency. Choosing the right brake affects not only crane performance but also safety levels and service life.

|

Project |

Drum Brake |

Disc Brake |

Wind-proof Brake |

Safety Brake System |

| Main Function | Main hoisting/travel brake | High-performance main brake | Prevent wind drift or overturning | Emergency and redundant protection |

| Suitable Conditions | General, medium & small tonnage | Heavy-load, high-speed, frequent start/stop | Outdoor & coastal environments | All high-safety requirement equipment |

| Braking Performance | Medium | High | Wind resistance | High |

| Heat Dissipation | General | Excellent | General | / |

| Maintenance Difficulty | Low | Medium | Medium | Medium-High |

| Cost | Low | High | Medium | High |

| Necessity | Standard for most conditions | Configured per application | Required for outdoor cranes | Recommended for high-safety equipment |

Brake Selection Principles

More complex working conditions → higher-grade brake configuration

Higher load and speed → stricter braking performance requirements

Outdoor cranes → consider wind resistance and corrosion protection

High safety level → prefer dual brakes and fail-safe designs

A proper brake configuration not only enhances crane performance but also serves as a core safety measure for personnel and equipment.

HSCRANE Brake Advantages

High reliability: HSCRANE brakes use high-quality friction materials and wear-resistant components, maintaining stable braking under frequent start/stop and heavy-load conditions, reducing failure rates and enhancing crane reliability.

Safety redundancy design: Supports dual-circuit and multi-brake configurations. In case of a circuit failure, the system can immediately switch to another, significantly improving overall safety, suitable for high-risk applications like ports and metallurgy.

Strong customization capabilities: Specialized designs for extreme environments such as sea wind, salt spray, high temperature, high humidity, and dust, ensuring long-term stable operation under harsh conditions.

Low maintenance cost: Modular and easily replaceable components reduce downtime, spare parts, and labor costs, providing long service life with minimal maintenance.

Compliance with international standards: Designed and manufactured in strict accordance with GB, ISO, FEM, and other global standards, meeting worldwide project requirements and reflecting HSCRANE’s quality control.

Wide industry applicability: HSCRANE brakes have been successfully applied in ports, shipyards, metallurgy, and energy equipment, demonstrating excellent reliability and adaptability across industries.

Maintenance and Inspection Recommendations

|

Item |

Maintenance Focus |

Risks & Impacts |

Recommended Frequency |

| Brake shoe clearance | Check for uniform and correct clearance between shoes and drum/disc; adjust springs or bolts if needed | Excessive or uneven clearance reduces braking performance or causes uneven wear/failure | Monthly; weekly for heavy-duty operation |

| Brake disc/drum wear | Inspect thickness, surface cracks, hot spots, or grooves; resurface or replace if needed | Severe wear can reduce braking or cause component failure, leading to safety risks | Quarterly; monthly for high-frequency use |

| Hydraulic/electromagnetic drive | Check hydraulic oil level, leaks, and pressure; test electromagnetic coil resistance, continuity, insulation | Drive failure can delay or prevent braking, compromising safety | Monthly inspection; semi-annual full function test |

| Safety release testing | Test brake release under power loss or pressure failure; verify spring force and return mechanism | Insufficient release may prevent emergency braking, causing accidents or equipment damage | Quarterly standard test |

Enhancing crane safety starts with the brake system. As the last line of defense, the brake protects the crane during emergency stops, heavy lifting, and harsh conditions. Its reliability directly affects operational stability and overall risk. By selecting, configuring, and using high-quality brakes, companies can extend crane lifespan, reduce unplanned downtime, and maintain safe, controlled operations in critical tasks.

Contact HSCRANE now to equip your cranes with safer and more reliable professional brake solutions!

For further safety improvements, buffers also play an essential protective role.

Click to learn more:What Is a Crane Buffer? A Complete Guide to Types and Functions