Abstract:

This article focuses on the selection of overhead crane parts of different tonnages, analyzing the differences in configuration. It covers hoisting mechanisms, wire ropes, hooks, running mechanisms, and electrical systems for small, medium, and large tonnage applications. As tonnage increases, components must be upgraded for load capacity, safety redundancy, and durability. The article summarizes common selection mistakes based on practical applications and highlights HSCRANE’s advantages in multi-tonnage configuration, customization, and technical support, providing guidance for the safe and efficient operation of overhead cranes.

The tonnage of an overhead crane determines its load capacity and directly affects the safety, reliability, and lifespan of its components. As the load increases, hoisting mechanisms, wire ropes, hooks, and braking systems face higher requirements for strength, performance, and safety. Ignoring tonnage differences in selection may result in excessive wear, decreased efficiency, safety risks, and increased maintenance costs. Therefore, appropriately configuring overhead crane parts based on tonnage is crucial for ensuring long-term stable operation.

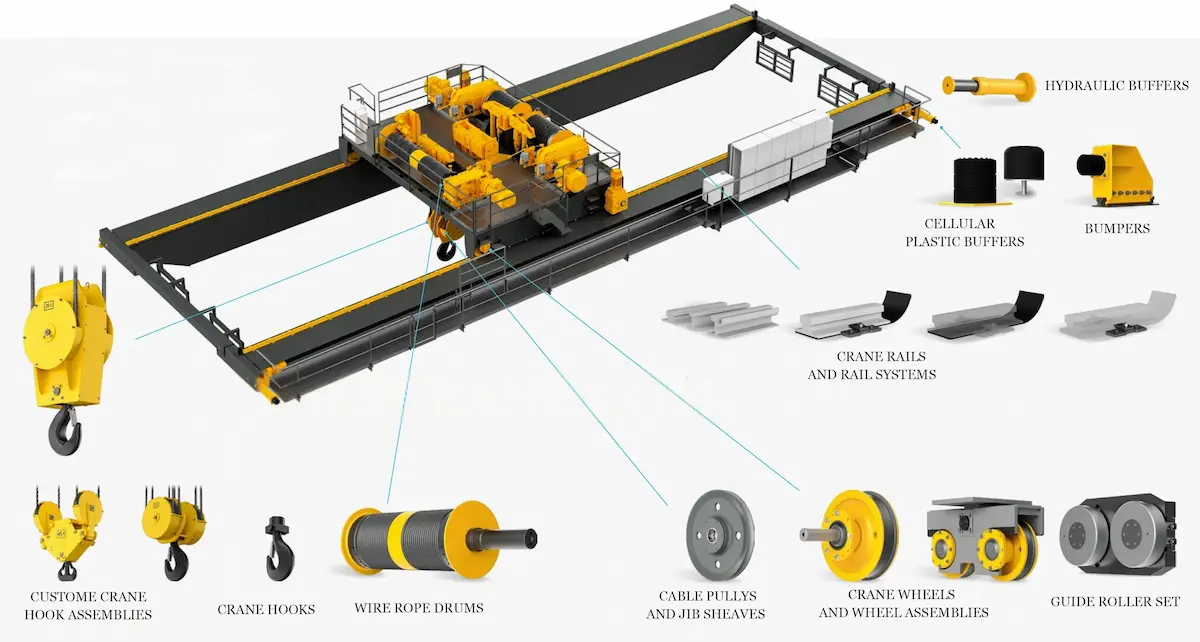

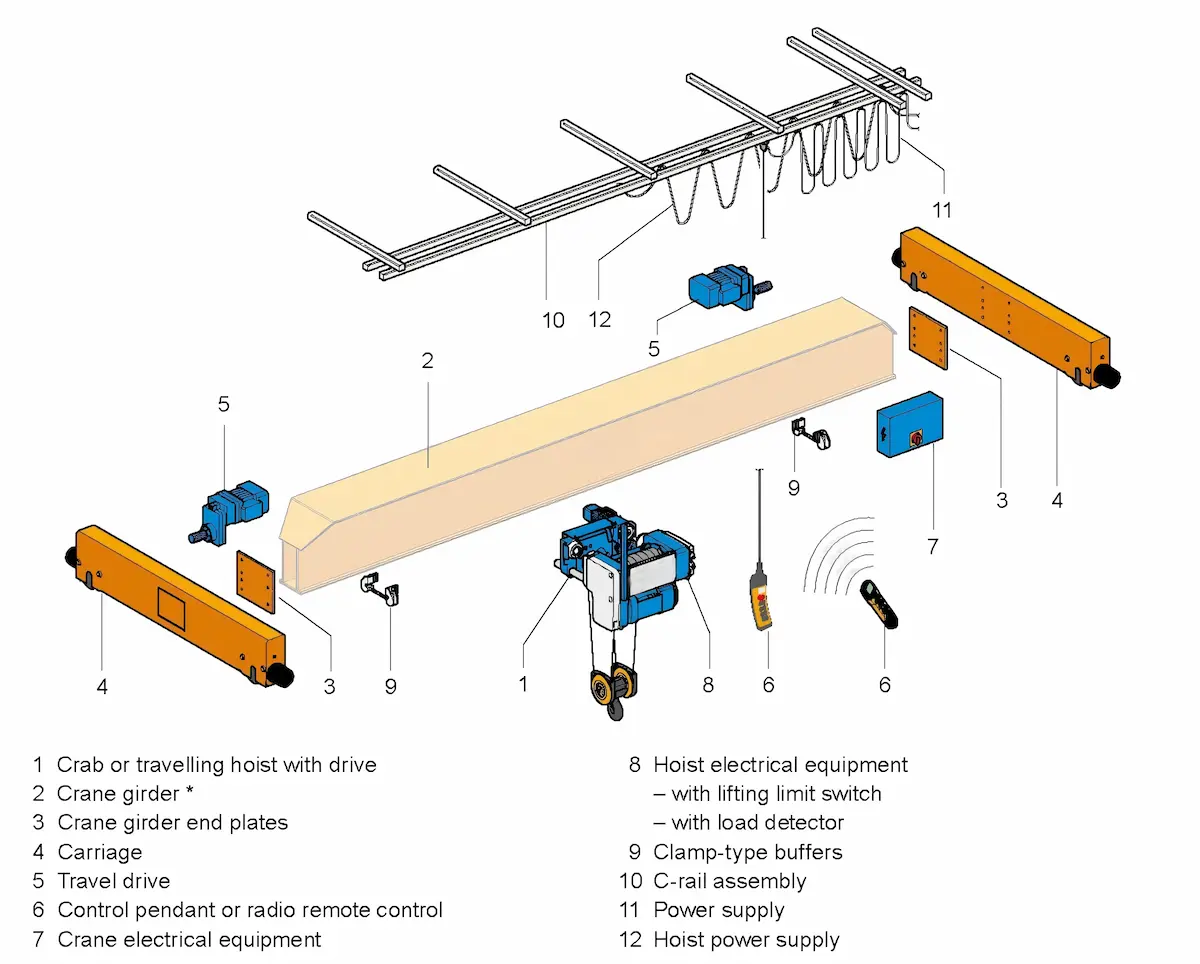

Overview of Common Core Overhead Cranes Parts

Overhead cranes consist of several key components working together to perform lifting, movement, and safety control functions. While the overall structure of overhead cranes is similar across different tonnages, there are noticeable differences in the specifications, performance grades, and configurations of core components. Before conducting tonnage selection analysis, it’s essential to systematically review these key components.

Hoisting Mechanism Components

The hoisting mechanism is the core load-bearing system of an overhead crane, directly determining the equipment’s lifting capacity, safety, and work efficiency. It typically includes the following critical components:

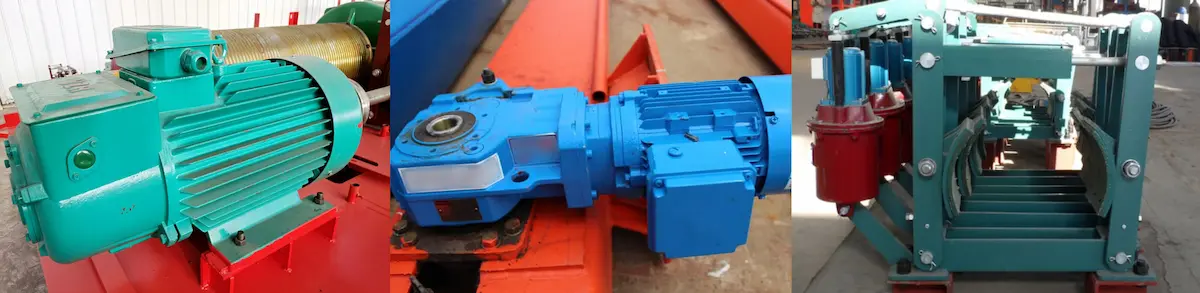

Hoisting Motor: Provides the lifting power. Depending on the crane’s tonnage and duty cycle, motor power, insulation level, cooling method, and duty cycle vary.

•Small-tonnage cranes often use standard asynchronous motors.

•Medium to large-tonnage cranes are typically equipped with heavy-duty or redundant design motors.

Reducer: Reduces speed and increases torque, ensuring smooth lifting operations. Common types include hardened gear reducers and planetary reducers. For large-tonnage equipment, higher load capacity and transmission efficiency are required.

Brakes: Primarily used for lifting stoppage and load holding, serving as key safety components. Depending on the tonnage, single or dual braking systems can be employed. Large-tonnage cranes usually require redundant brake systems to enhance safety and reliability.

Steel Rope and Hook Assembly

Steel ropes and hooks are directly responsible for carrying the load, and their safety factor and durability differ significantly across various crane tonnages.

Steel Ropes: The diameter, structural form, tensile strength, and service life requirements increase as lifting tonnage increases. Large-tonnage cranes generally use multi-rope lifting systems to distribute the load and improve safety.

Hook Assembly: Includes the hook body, pulley group, and bearings.

•Small-tonnage cranes typically use single-hook structures.

•Medium to large-tonnage cranes employ high-strength forged hooks, dual hooks, or hook assemblies, equipped with anti-detachment devices and wear detection designs.

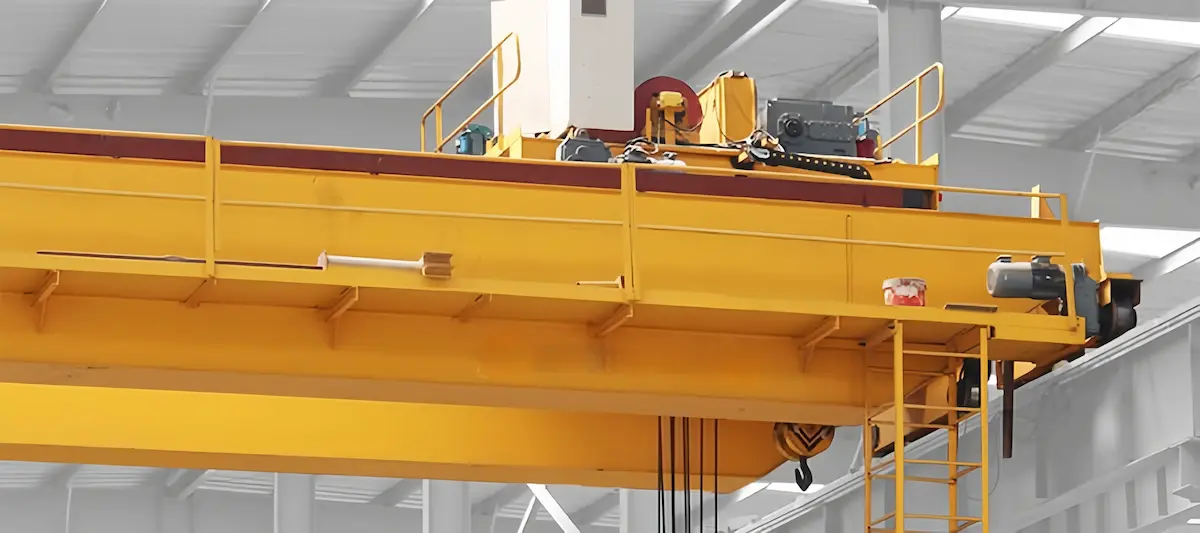

Trolley Running Mechanism and Wheel Group

The trolley running mechanism is responsible for the horizontal movement of the hoist trolley on the main beam, with its performance directly impacting operational stability and positioning accuracy.

Running Motor and Drive Mode: The larger the tonnage, the higher the drive force and synchronization required. Common configurations include centralized and separate drive modes.

Wheel Group: Includes wheel material, diameter, load design, and bearing types.

•Small-tonnage cranes typically use standard forged steel wheels.

•Large-tonnage cranes require high-load alloy steel wheels and heavy-duty bearings to withstand higher wheel loads and long-term operational needs.

Main Beam Structure and Connecting Parts

The main beam is the primary load-bearing structure of the overhead crane. Its design and manufacturing quality directly influence the overall rigidity and service life of the crane.

Main Beam Structure: The common structure is a box beam design, with noticeable differences in plate thickness, stiffener arrangement, and welding processes based on tonnage.

Connecting Parts and Structural Components: Includes end beam connections, bolts, and pins. Medium to large-tonnage overhead cranes typically use high-strength connectors and undergo rigorous stress and fatigue calculations.

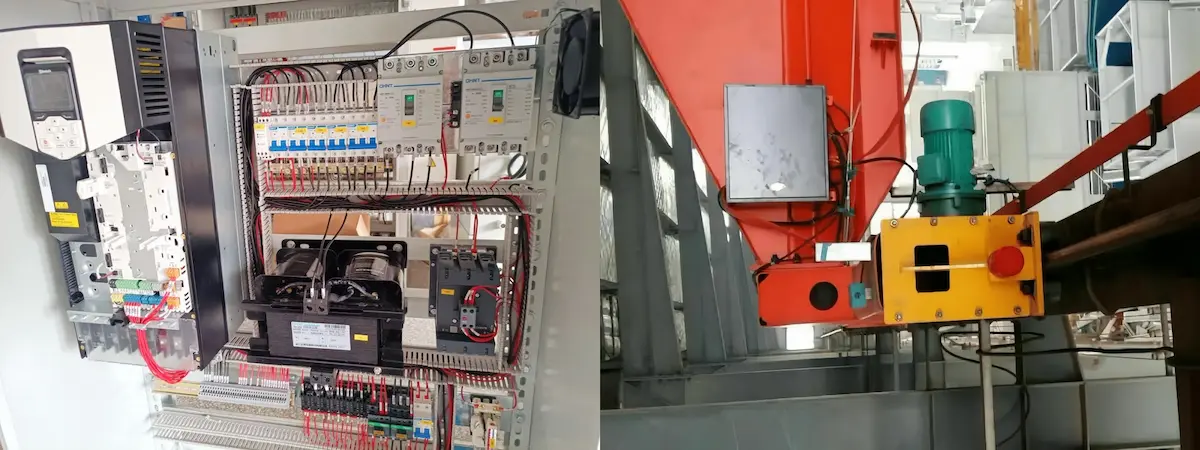

Electrical Control System and Safety Protection Devices

The electrical system is the core for precise control and safe operation of the overhead crane.

Control System: Includes control cabinets, frequency converters, and operation modes (joystick, remote control, cabin). As tonnage increases, the precision and system stability requirements also rise.

Common Safety Protection Devices Include:

•Load limiters

•Travel limit switches

•Anti-collision and anti-sway systems

•Emergency stop and fault alarm functions

Medium to large-tonnage cranes typically feature higher-level electrical protection and multiple safety interlock designs.

Analysis of Component Configuration Differences for Overhead Cranes of Different Tonnages

|

Component Category |

Small-Tonnage Overhead Crane (5–10 tons) |

Medium-Tonnage Overhead Crane (20–50 tons) |

Large-Tonnage Overhead Crane (75 tons and above) |

| Overall Component Features | Compact structure, lightweight design, standardized configuration | Focus on load capacity and operational stability | Heavy-duty configuration, emphasizing safety redundancy and customization |

| Hoisting Motor | Standard asynchronous motor with moderate power | High-power heavy-duty motor with higher duty class | Dedicated heavy-duty motor supporting continuous high-load operation |

| Gearbox | Standard hardened gear reducer | High-capacity hardened or planetary gearbox | Heavy-duty planetary gearbox with multi-stage transmission |

| Braking System | Single brake configuration | Dual brake configuration for improved safety | Multiple redundant braking systems with safety interlocks |

| Wire Rope | Standard diameter wire rope with basic safety factor | Larger diameter rope with enhanced wear and fatigue resistance | Multi-rope structure with high-strength ropes and ultra-high safety factor |

| Hook Assembly | Single hook structure with standard rating | High-grade forged hook or double hook structure | High-strength hook block for ultra-heavy-duty conditions |

| Trolley Traveling Mechanism | Standard travel motor with simple structure | Enhanced driving force with smoother operation | Multi-drive or synchronous drive design for precise operation |

| Wheels and Bearings | Standard forged steel wheels | High-load wheels with heavy-duty bearings | Special alloy steel wheels with ultra-heavy-duty bearings |

| Main Girder Structure | Standard box girder with thinner plates | Reinforced box girder with increased rigidity | Customized girder with focused fatigue and stress verification |

| Electrical Control System | Conventional control system with basic protection | Higher-level electrical protection with operation monitoring | High-performance control system with intelligent monitoring and fault warning |

| Safety Protection Devices | Basic limit switches and overload protection | Comprehensive safety protection and interlock systems | Multiple safety protections with redundancy and intelligent safety management |

| Typical Applications | Light manufacturing, warehousing, assembly workshops | Heavy manufacturing, machining, steel structure workshops | Metallurgy, power generation, shipbuilding, heavy assembly manufacturing |

Summary of Overhead Crane Parts Configuration Differences

•Higher tonnage requires greater safety redundancy: Large tonnage overhead cranes use redundant braking, wire rope, and electrical safety designs to reduce high-load risks.

•Medium tonnage is the key upgrade range: Compared with small tonnage, medium tonnage overhead cranes show clear upgrades toward heavy-duty configurations.

•Large tonnage emphasizes customized selection: Overhead cranes of 75 tons and above require customized components for specific working conditions.

Tonnage Impact on Key Overhead Crane Parts

As overhead crane tonnage increases, load, operating stress, and safety risks grow exponentially. To ensure safe, stable, and long-term reliable lifting operations, all core components must be upgraded simultaneously in performance parameters, structural design, and safety redundancy.

Hoisting Mechanism: Power, Braking, and Duty Changes

Hoisting power changes: higher tonnage requires higher motor power and stronger starting torque and continuous running capability.

•Small tonnage cranes often meet intermittent duty requirements.

•Medium and large tonnage cranes must operate stably under heavy load, avoiding overheating and performance degradation.

Braking upgrade: braking safety importance rises with lifting capacity.

•Small tonnage cranes usually use single brakes.

•Medium tonnage cranes commonly use dual brake systems.

•Large tonnage cranes require multiple redundancy and safety interlocks to prevent major risks from brake failure.

Duty level increase: higher tonnage usually requires higher duty class, demanding better fatigue resistance and longer service life.

Steel Rope and Hook: Safety Factor and Durability

Safety factor increase: higher tonnage demands higher safety factors to handle impact loads, eccentric loads, and frequent starts and stops.

Steel rope structure changes:

•Small tonnage cranes use single or small-diameter ropes.

•Medium tonnage cranes use larger diameter ropes with better wear and fatigue resistance.

•Large tonnage cranes often use multi-rope hoisting systems to distribute load and reduce stress on each rope.

Hook durability requirements: hook grade increases with tonnage. Large tonnage cranes use high-strength forged hook assemblies with wear monitoring and anti-detachment design.

Safety factor increase: as tonnage rises, wire ropes and hooks must have higher safety factors to handle impact loads, eccentric loads, and frequent starts.

Running Mechanism: Wheel Material, Bearings, and Drive Differences

Wheel material upgrade: higher tonnage means higher wheel pressure.

•Small tonnage cranes use standard forged steel wheels.

•Medium tonnage cranes require high-load alloy wheels.

•Large tonnage cranes use special wear-resistant wheels to reduce rail wear.

Bearing configuration changes: large tonnage mechanisms use heavy-duty or special bearings to resist high load and long continuous operation.

Drive method differences: higher tonnage demands better synchronization and driving force.

•Small tonnage often uses single or centralized drive.

•Medium and large tonnage cranes use multi-point or separate drives to improve stability and positioning.

Electrical System: Control Precision, Safety, and Intelligence

Control precision increase: large tonnage cranes require higher speed and positioning precision, usually using VFD control for smooth start and accurate operation.

Safety level increase: higher tonnage requires higher electrical safety level, with more complete overload, limit, and alarm protection.

Intelligence level increase: large tonnage cranes increasingly adopt smart monitoring, fault diagnosis, and remote maintenance to reduce risks and downtime.

HSCRANE Overhead Crane Parts Selection Advantages

Rich Tonal Coverage and Customization Capabilities

•HSCRANE’s Overhead Crane Parts cover a wide range of applications, from small tonnage to ultra-large tonnage, with flexible configurations based on lifting capacity, span, duty cycle, and specific operating conditions.

•For medium-to-large tonnage and special condition projects, HSCRANE offers customized component selection to ensure that each configuration is closely aligned with actual operational needs in terms of safety and performance.

High Standard Components and Reliable Quality

•HSCRANE adheres to using high-standard core components, ensuring that critical parts are rigorously tested for strength, wear resistance, and service life.

•From lifting mechanisms, wire ropes, and hooks to running mechanisms and electrical systems, all components are designed and manufactured according to international standards such as ISO, FEM, and CMAA. This enhances the overall stability and long-term reliability of the crane, reducing the customer’s future maintenance costs.

Professional Selection Support and Technical Services

•HSCRANE boasts a professional technical team that can provide component selection advice for different tonnages and operational conditions during the early stages of a project.

•By carefully considering usage frequency, operating environment, and future expansion needs, HSCRANE helps clients avoid issues of under- or over-configuring components, achieving a reasonable balance between safety, performance, and investment costs.

Multi-brand Compatible Overhead Crane Parts Solutions

•HSCRANE provides compatible component support for overhead cranes from various international brands, including Demag, Konecranes, ABUS, etc., fulfilling repair, replacement, and upgrade requirements.

•Under the premise of ensuring interface compatibility and equivalent performance, HSCRANE offers more flexible component selection options and competitive cost advantages.

Urgent Response and Fast Shipping Services

•For projects with high downtime risks or tight delivery schedules, HSCRANE offers urgent component services to reduce waiting times.

•Through an optimized inventory system and efficient logistics, HSCRANE ensures the rapid dispatch of commonly used components, helping customers reduce downtime losses and ensuring continuity in production.

Common Mistakes and Suggestions in Overhead Crane Parts Selection

During the component selection process for overhead cranes, lack of systematic consideration can lead to insufficient equipment performance or wasted investment costs. Below are common mistakes based on actual applications and corresponding suggestions.

Focusing Only on Tonnage and Ignoring Working Conditions and Frequency

Common Mistake: Some users focus primarily on the rated lifting capacity when selecting components, neglecting the actual working conditions such as duty cycle, operating hours, lifting speed, and environmental conditions.

Potential Risks: In high-frequency or heavy-load conditions, even if the tonnage meets the requirements, insufficient strength and work level of the components may cause risks.

•Overload wear on the lifting mechanism

•Declining brake system reliability

•Significantly reduced equipment lifespan

Selection Suggestion: In addition to tonnage, consider duty cycle and actual operational intensity. Properly match the lifting mechanism, braking system, and running components to ensure long-term, stable equipment operation.

Overly Low or Overly High Configuration Leading to Cost Waste

Common Mistakes:

•Low Configuration: Selecting components with specifications lower than actual needs to reduce initial procurement costs.

•High Configuration: Blindly pursuing high standards or redundant configurations, exceeding actual operational needs.

Potential Impact:

•Low configuration can cause safety hazards and frequent failures, increasing maintenance and downtime costs.

•Overly high configuration leads to excessive initial investment, with performance not fully utilized.

Selection Suggestion: Ensure safety first, and match component grades according to actual operational conditions. Achieve a balance between performance and cost, avoiding over-design or under-configuration.

Ignoring Future Expansion Needs and Lack of Forward-Looking Selection

Common Mistake: Some projects only consider current operational needs without reserving space for future capacity upgrades or process improvements.

Potential Issue: When production scale increases or heavier loads are required, the existing crane may not meet the demand, leading to a complete replacement or repeated investment.

Selection Suggestion: If conditions allow, it is recommended to reserve upgrade space for key components to better accommodate future expansion needs, thereby increasing the overall investment value of the equipment.

As the tonnage of cranes changes, the lifting mechanisms, wire ropes and hooks, running mechanisms, and electrical control systems need to be upgraded in performance, safety redundancy, and durability. Only by matching the components to the actual tonnage, duty cycle, and working conditions can operational risks be effectively reduced, the service life of the equipment be extended, and long-term stable and efficient lifting operations be achieved.

In the actual selection process for overhead crane parts, blindly pursuing low costs or stacking high configurations will affect the overall performance and economic efficiency of the equipment. Through systematic analysis of the component differences caused by tonnage variations, and forward-looking selection based on future development needs, a true balance of safety and economy can be achieved.

Our professional engineers will provide you with safe, reliable, and cost-effective overhead crane parts selection and customization solutions based on your lifting capacity, working conditions, and usage needs.

After understanding the differences in overhead crane component configurations for various tonnages, it is also critical to choose a reliable crane parts supplier.

Click to learn: [How to Choose a Reliable Crane Parts Supplier in China]

FAQ

Q1: Is tonnage the main factor for component selection?

A1: Tonnage is essential, but working level, frequency, height, and environment also matter. Relying only on tonnage may reduce lifespan and safety.

Q2: Why do same-tonnage cranes have different components?

A2: Different conditions need different strength and durability. High-frequency heavy loads require higher-grade parts, so configurations differ.

Q3: Are double brakes needed for medium-tonnage cranes?

A3: Yes, for high-frequency or high-safety operations. Double brakes improve reliability and reduce failure risk.

Q4: Why do large cranes use multi-rope lifting?

A4: Multi-rope systems distribute load, reduce rope stress, and improve safety and service life.

Q5: Should future expansion be considered?

A5: Yes. Reserve upgrade space to adapt to future capacity increases and avoid repeat investment.

Q6: Can HSCRANE provide customized solutions?

A6: Yes. HSCRANE offers professional selection and customized solutions for safe, efficient, and stable operation.

Below is a checklist for overhead cranes and their components, which you can download:

Daily Inspection

Monthly Inspection

Annual / Periodic Inspection

This document is for reference only. Specific operations must strictly comply with local laws and regulations and equipment manuals.