Abstract:

With advancing industrial automation, cranes face higher demands for operating efficiency and safety. Traditional control methods increasingly show limitations in accuracy, response speed, and safety protection. PLC control systems offer high reliability, flexible programming, and strong system integration. They have become the core of modern crane control solutions. Automated operation and coordinated multi-mechanism control enable precise and efficient crane movement. These functions significantly improve efficiency while reducing energy consumption and equipment wear. Integrated safety protection, real-time monitoring, and fault diagnosis effectively ensure safe operation. Based on mature PLC solutions, HSCRANE delivers efficient, reliable, and scalable crane systems.

Cranes are essential industrial equipment used in manufacturing, shipyards, energy, and logistics sectors. Their operating efficiency and safety directly affect overall production performance. Traditional control methods show growing limitations in precision, response speed, and safety protection. These limitations make it difficult to meet modern industry requirements for efficient and safe operations. PLC control systems provide stability, flexibility, and intelligent control capabilities. They are becoming the core solution for modern crane control systems.

Overview of PLC Control Technology

With continuous industrial automation advancement, cranes as key material handling equipment require ongoing control system upgrades. PLC systems offer high stability, strong control accuracy, and excellent scalability. They have become a core technology in modern crane control systems.

Basic Principles of PLC

A PLC is a digital control device designed for industrial environments. It processes input signals through logic operations, sequence control, timing, and counting. It outputs control commands to achieve precise equipment operation control.

In crane applications, PLCs complete control tasks through the following processes:

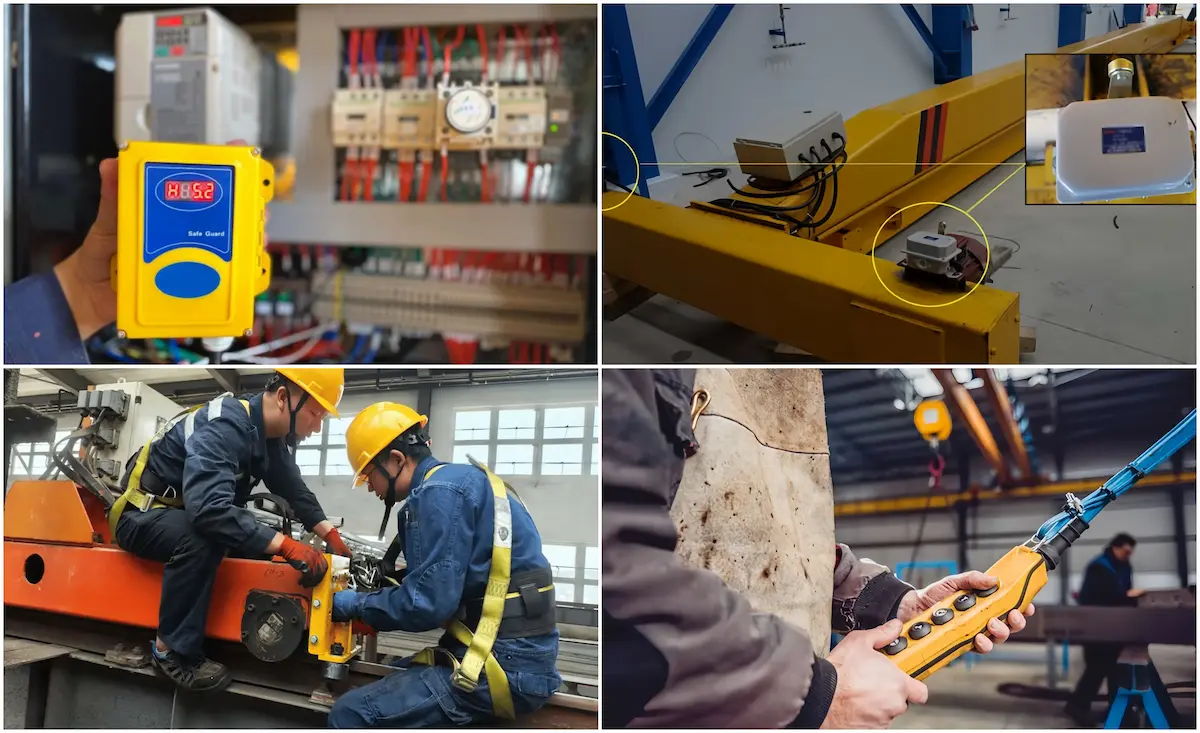

• Signal acquisition: Collects inputs from buttons, sensors, limit switches, and encoders.

• Logic processing: Performs judgment, calculation, and control logic based on preset programs.

• Output control: Sends commands to motors, inverters, brakes, and other actuators.

• Status feedback: Monitors operating status in real time to form closed-loop control.

This software-based control method makes crane operation more stable, flexible, and controllable.

Application Characteristics of PLC Control Systems in Industrial Automation

• High reliability: Industrial-grade hardware resists interference and adapts to heat, dust, and vibration environments.

• Fast real-time response: Short execution cycles enable rapid response to commands and safety signals.

• Flexible programming and expansion: Control logic can be customized for different conditions and future upgrades.

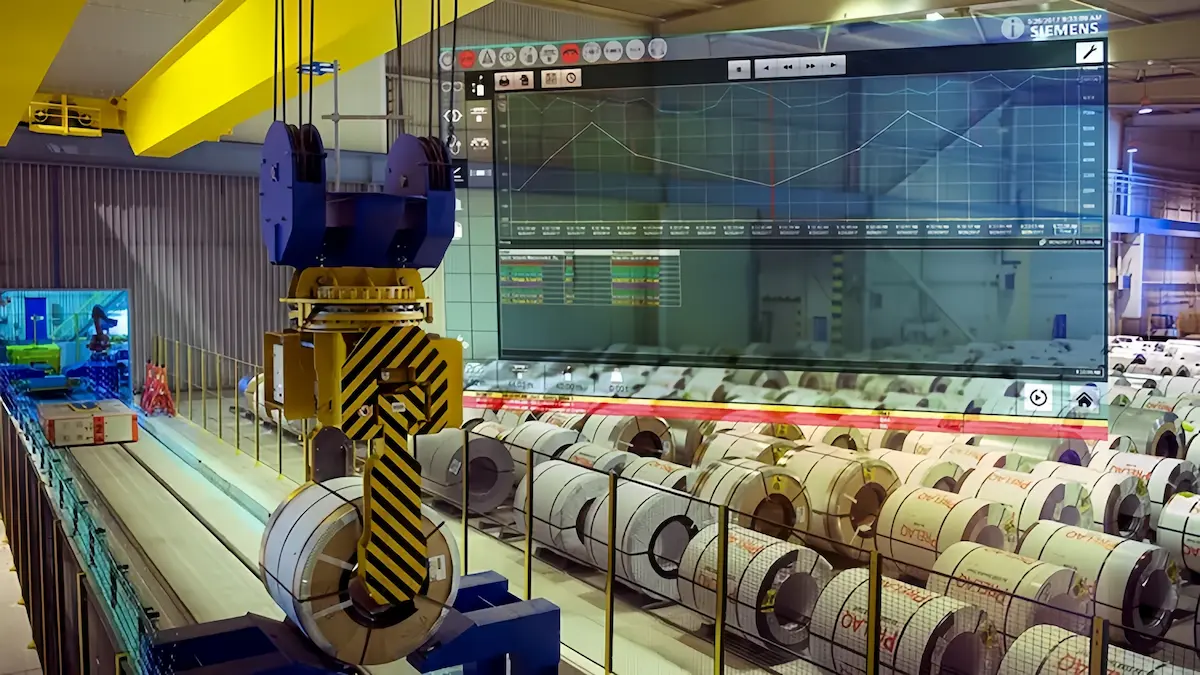

• Strong system integration: PLCs connect seamlessly with inverters, sensors, HMI, and SCADA systems.

Comparison Between PLC and Traditional Relay Control Systems

Compared with traditional relay control, PLC technology shows clear advantages in precision, safety, and efficiency.

|

Comparison Item |

PLC-Controlled Crane |

Traditional Relay-Controlled Crane |

| Control accuracy | Program-based control with precise speed and position control and high repeatability | Relies on mechanical contacts with lower control accuracy |

| Operating efficiency | Supports automated operation and multi-mechanism coordination | Mainly manual operation with efficiency affected by human factors |

| Safety performance | Enables multiple safety logics, real-time monitoring, and automatic protection | Limited safety functions with slower response speed |

| Fault diagnosis capability | Includes self-diagnosis and alarm functions with clear fault identification | Fault troubleshooting relies on manual inspection and takes longer |

| System stability | Strong anti-interference capability with stable and reliable long-term operation | Contacts are prone to aging, reducing long-term stability |

| Maintenance cost | Simplified wiring with convenient maintenance and lower overall cost | Complex wiring with higher maintenance and replacement costs |

| Expansion and upgrade capability | Easy functional upgrades and supports intelligent system expansion | Difficult to expand with high upgrade costs |

These comparisons show PLC systems outperform traditional controls in efficiency, safety, and lifecycle cost.

How PLC Control Technology Improves Crane Operating Efficiency

Through precise control and intelligent management, PLC systems enable more efficient crane operation. They also improve operating accuracy, reduce energy consumption, and extend equipment service life.

Automation and Intelligent Operation of Crane Processes

• Automatic control of start, stop, acceleration, deceleration, and positioning: The PLC system automatically controls starting, stopping, acceleration, and deceleration. It also ensures accurate positioning based on preset programs. This significantly reduces operator intervention, improves efficiency, and ensures smooth crane operation.

• Coordinated multi-mechanism operation to reduce manual intervention: In multifunction cranes, hoisting, traveling, and trolley mechanisms must operate in coordination. PLC systems enable synchronized operation of these mechanisms, minimizing manual control and improving overall efficiency.

Improved Operating Accuracy and Working Efficiency

• Precise control of hoisting, traveling, and trolley speeds: PLC systems adjust component speeds based on real-time signals. This ensures accurate operation of hoisting, traveling, and trolley mechanisms. Precise control reduces operational errors and avoids time loss caused by inaccurate movements.

• Reduced no-load operation and misoperation time: Intelligent scheduling allows the crane to identify load conditions automatically. Unnecessary no-load operation is avoided. Optimized control logic reduces misoperations and ensures each action occurs under optimal conditions.

Optimized Energy Consumption and Equipment Utilization

• Energy-efficient operation through integration with variable frequency drives: PLC systems work with VFDs to adjust motor frequency and power. Adjustment is based on actual load and operating conditions. This optimizes energy distribution, reduces consumption, and decreases motor wear.

• Reduced mechanical impact and extended component service life: Smooth acceleration and deceleration control reduces mechanical shock. Equipment stress is minimized. This improves operational stability and extends the service life of key crane components.

Applications of PLC Control Technology in Enhancing Crane Safety

• Multiple safety protection logics: Integrated overload protection, travel limits, and anti-collision control functions. The system intervenes automatically under abnormal conditions to prevent accidents.

• Emergency stop and fault self-locking: The crane stops immediately when faults or danger signals are detected. The system locks to prevent secondary misoperations.

• Real-time monitoring and fault diagnosis: Key parameters such as load, current, and speed are monitored in real time. Abnormal conditions trigger alarms and enable accurate fault identification.

• Reduced risk of human error: Standardized control logic and remote monitoring reduce misoperations. Overall safety management efficiency is improved.

PLC Control Systems Applications in Different Crane Types

Different crane types vary in operating environments, duty cycles, and load characteristics. PLC control systems offer high flexibility and reliability. They can be customized for specific scenarios. This ensures safe, efficient, and stable operation under complex conditions.

PLC Control Applications for Overhead Cranes

• PLC provides unified control for hoisting, bridge travel, and trolley mechanisms. Smooth start and stop are achieved. Positioning accuracy is improved.

• Multi-mechanism coordinated operation is supported. Manual intervention is reduced. Workshop and production line efficiency is improved.

• Suitable for frequent start stop and repetitive duty cycles. Equipment wear is effectively reduced.

Automation Control for Gantry Cranes and Shipyard Cranes

• PLC systems integrate wind protection, anti-sway, and anti-collision logic. They adapt to large spans and long travel distances.

• Multiple cranes can operate in linkage with centralized management. Overall efficiency improves in ports and shipyards.

• Suitable for outdoor, heavy duty, and complex environments. Long-term stable operation is ensured.

Stable Performance Under Heavy Load and Continuous Operation

• PLC systems provide industrial-grade reliability and strong anti-interference capability. They meet high intensity continuous operation demands.

• Key operating parameters are monitored in real time. Safe and stable operation under heavy loads is ensured.

• Optimized control logic reduces mechanical impact. Service life of key components is extended.

Advantages of HSCRANE PLC Control Systems

• Mature and reliable PLC solutions: HSCRANE adopts industrial PLC systems. Control architecture is stable. Programming follows strict standards. Long-term reliability is ensured.

• Integrated safety and efficiency design: Multiple safety logics are embedded. Overload, limits, and fault locking are included. Efficiency and safety are balanced.

• Extensive project experience and customization capability: Control logic is tailored to customer conditions. Optimal performance is ensured.

• Comprehensive pre-sales and after-sales support: Full lifecycle technical support is provided. Operating and maintenance costs are reduced.

Scalability and Future Trends of PLC Control Systems

With advancing automation and digitalization, crane control systems are evolving toward intelligence. PLC systems offer strong openness and scalability. They form the core platform for future crane development.

|

Expansion Direction |

Application Description |

Value Delivered |

| Integration with remote monitoring and SCADA systems | Seamless connection with monitoring platforms through industrial networks. Centralized supervision and unified crane management are achieved. | Equipment status, alarms, and operations are monitored in real time. Overall management efficiency is improved. |

| Data acquisition and equipment condition analysis | Key data such as load, runtime, motor current, and faults are continuously collected. Long term analysis is performed. | Potential risks are identified early. Preventive maintenance is enabled. Unplanned downtime is reduced. |

| Foundation for intelligent and unmanned crane operation | PLC logic expansion and data interfaces support intelligent control and automated coordinated operations. | Crane intelligence is enhanced. Automation level and operational reliability are improved. |

With rising automation and intelligent manufacturing, PLC control has become essential for modern cranes. PLC control systems enhance automation, precision, safety, and scalability. Crane efficiency and safety are significantly improved. Stable and sustainable production is strongly supported.

Looking ahead, efficiency, safety, and intelligence will define crane control trends. PLC technology will integrate with digital management and analytics. Cranes will move toward higher intelligence and unmanned operation.

Contact HSCRANE for advanced and proven PLC control solutions. Reliable and efficient crane systems are provided. Your competitiveness and long-term growth are supported.

Further Reading

In multi-crane or complex environments, anti-collision control is critical. PLC-based systems enable real-time monitoring and active intervention. Collision risks are effectively reduced.

●Learn more: Crane Anti-Collision System Solutions: Enhancing Equipment Reliability and Operational Safety

FAQ

Q1: What is the main advantage of PLC-controlled cranes?

A1: PLC cranes enable automation, precise control, and multiple safety protections. They outperform relay systems in efficiency, safety, diagnostics, and scalability.

Q2: Are PLC control systems suitable for all crane types?

A2: Yes. PLC control systems are highly flexible. They can be customized for overhead, gantry, and shipyard cranes.

Q3: How do PLC systems improve crane safety?

A3: PLC integrates overload, limit, anti-collision, emergency stop, and fault locking logic. Full-process monitoring and active protection are achieved.

Q4: Can PLC control reduce energy consumption?

A4: Yes. PLC works with VFDs to optimize motor control. Energy consumption is reduced. Mechanical impact is minimized.

Q5: Is future upgrading and expansion convenient?

A5: Yes. PLC control systems support SCADA integration, data acquisition, and intelligent analysis. They enable future intelligent and unmanned cranes.

Q6: Does HSCRANE support customization and technical service?

A6: Yes. HSCRANE provides customized PLC solutions. Complete pre-sales, commissioning, and after-sales support are available.

This document is for reference only. Specific operations must strictly comply with local laws and regulations and equipment manuals.