Abstract:

The crane rail is a fundamental system that ensures the safe, stable, and efficient operation of lifting equipment, playing a critical role in high-intensity operating environments such as industrial workshops, ports, shipyards, and storage yards. This article systematically explains the definition, basic functions, and structural components of crane rails, and provides an in-depth analysis of their core value in load bearing, motion guidance, force transmission, and safety and service life assurance. At the same time, common crane rail types and their applicable working conditions are compared, and practical, engineering-oriented selection principles are proposed by considering crane type, load class, operating environment, and future expansion requirements. By emphasizing the foundational role of the rail system within the entire lifting system, the article highlights that only by giving full attention to crane rails during design, selection, installation, and maintenance can operational risks be effectively reduced, equipment service life extended, and the long-term operational efficiency of lifting systems enhanced.

In industrial production, port cargo handling, and shipyard operations, cranes are required to perform high-intensity and high-frequency lifting tasks. Compared with the crane structure itself, the crane rail is often overlooked, yet it is the fundamental system that determines whether the equipment can operate safely and reliably over the long term.

During operation, a crane is subjected not only to large vertical loads, but also to complex forces generated by starting, braking, and eccentric loading. If the rail system is improperly designed or poorly installed, it may lead to reduced running smoothness and operating efficiency, and in severe cases, equipment failures or even safety accidents. Therefore, a comprehensive understanding of the structure, function, and operational impact of crane rails is a crucial prerequisite for ensuring reliable crane operation.

What Is a Crane Rail

A crane rail refers to a specialized track system used to support, guide, and carry crane movement, and is a key component of the crane traveling mechanism. By working in conjunction with crane travel wheels, the rail allows the crane to move smoothly along a fixed path while safely transferring the crane’s self-weight, rated load, and various forces generated during operation to the supporting structure or foundation.

Basic Functions and Characteristics of Crane Rails

During operation, crane rails mainly perform the following functions:

▪ Load bearing: Supporting the crane’s self-weight, lifted loads, and additional dynamic loads

▪ Guidance: Ensuring straight-line travel along the designed route and preventing misalignment

▪ Force transmission: Transferring vertical forces, horizontal forces, and braking forces to the runway beams or foundation

▪ Operational support: Providing smooth and continuous running conditions for the crane

Compared with ordinary transportation rails, crane rails have the following distinctive characteristics:

▪ High load-bearing capacity to accommodate heavy loads and impact conditions

▪ Strict accuracy requirements, especially for straightness and levelness

▪ Complex operating environments, often involving high dust, high humidity, or outdoor exposure

▪ Strong system integration, requiring close coordination with the overall crane structure

Structural Components of Crane Rails

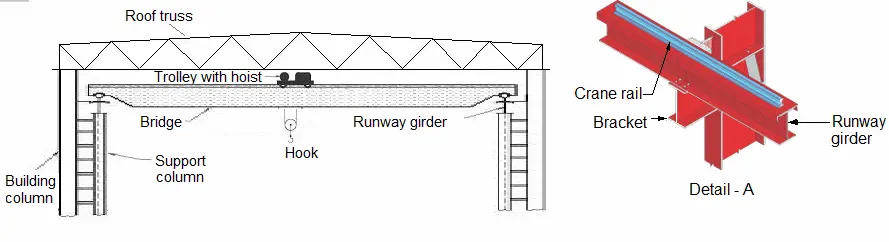

A crane rail system typically consists of multiple coordinated components that together form a complete runway system.

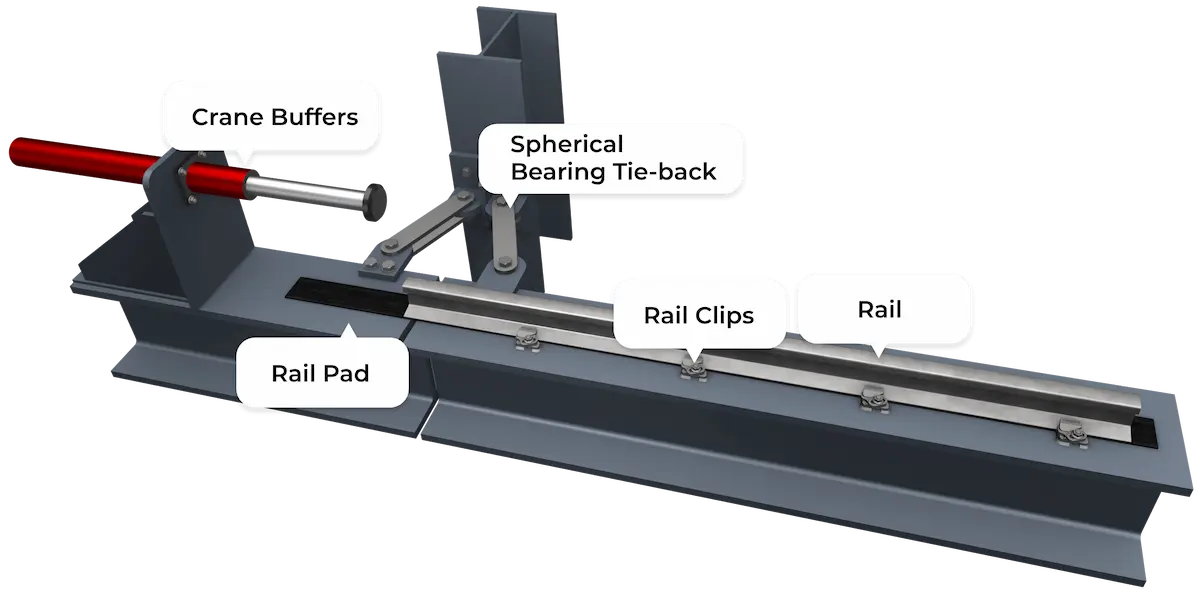

• Rail steel: Rail steel is the core component of the crane rail, directly in contact with the crane wheels. Its primary function is to withstand wheel loads while ensuring wear resistance and smooth operation.

• Runway beam: The runway beam supports the rail steel and further transfers loads to the building structure or concrete foundation. Depending on the application, runway beams may be constructed of steel or reinforced concrete.

• Fastening and fixing devices: These devices secure the rail steel to the runway beam. Common forms include clips, bolts, welding, or elastic fastening systems. They must ensure reliable fixation while allowing for a certain degree of thermal expansion and contraction.

• Base plates and elastic elements: Base plates or elastic materials are typically installed between the rail steel and the runway beam to adjust elevation, distribute stress, and reduce vibration and noise, thereby improving crane traveling smoothness.

(Taking a single-girder overhead crane as an example)

The Core Role of Crane Rails in Lifting Systems

▪ Load Bearing and Force Transmission:

Crane rails not only support the crane’s self-weight and the vertical loads generated by lifted loads, but also withstand horizontal forces, braking forces, and impact loads caused by starting and stopping during operation. These complex forces must be safely and evenly transferred to the runway beams and foundation structures to ensure overall system stability.

▪ Travel Guidance and Accuracy Assurance:

The straightness, levelness, and installation accuracy of the crane rail directly determine the smoothness of crane travel and positioning accuracy. A stable rail system effectively prevents misalignment, rail gnawing, and abnormal travel behavior, ensuring reliable and precise crane operation during lifting tasks.

▪ Support for Efficiency and Safety:

High-stability crane rails reduce running resistance and equipment vibration, improving crane operating efficiency while minimizing wear on key structural components and traveling mechanisms. This helps reduce failure rates and safety risks at their source.

Common Types of Crane Rails and Applicable Scenarios

Common Crane Rail Types

|

Rail Type |

Structural Features |

Performance Characteristics |

Applicable Crane Types |

Typical Application Scenarios |

| Steel Rail System | Uses standard railway rails or heavy-duty steel rails; mature design with strong versatility | High load-bearing capacity and proven construction experience; higher requirements for installation accuracy and foundation rigidity | Overhead crane, gantry crane, semi-gantry crane | Industrial workshops, general ports, warehousing and logistics areas |

| Dedicated Crane Rails | Rail profiles specially designed for crane duty, optimized cross-sections for high wheel loads | Excellent wear resistance and fatigue performance; smooth operation suitable for high-frequency and heavy-duty service | Heavy-duty overhead crane, metallurgical crane, port cranes | Port terminals, metallurgical workshops, heavy industrial facilities |

| Combined Rail Systems | Integrated system consisting of rail steel, elastic pads, fastening devices, and runway beams | Uniform load distribution, effective vibration and noise reduction, high overall stability, low maintenance cost | Automated cranes, high-precision positioning cranes | Automated factories, shipyards, continuous production lines |

Typical Application Scenarios for Crane Rails

• Industrial Workshops: In manufacturing plants, crane rails are typically arranged along building column lines to provide a stable travel path for overhead cranes, supporting material handling and production assembly operations.

• Ports: In port environments, crane rails must withstand high loads, high operating frequencies, and harsh environmental conditions, placing extremely high demands on durability and stability.

• Shipyards: Crane rails in shipyards are commonly used for large block lifting and hull construction. They feature long spans and concentrated loads, requiring strict control of foundation integrity and rail installation accuracy.

• Storage Yards: In logistics yards or heavy equipment storage areas, crane rails are often installed outdoors and must offer excellent weather resistance and long-term stability to adapt to continuous outdoor operation.

Impact of Crane Rails on Equipment Safety and Service Life

Crane rails have a direct and far-reaching impact on equipment safety and service life, mainly reflected in the following aspects:

▪ Operational Safety Assurance:

Uneven rails, excessive wear, or large installation deviations can lead to uneven wheel load distribution, resulting in rail gnawing, misalignment, and abnormal operation. Over time, these issues may cause structural fatigue or even severe safety accidents such as derailment.

▪ Service Life of Key Components:

Insufficient rail accuracy significantly increases running resistance in the crane traveling mechanism, accelerating wear of wheels, bearings, gearboxes, and other critical components. This shortens component service life and increases failure rates and maintenance frequency.

▪ Overall Crane Longevity and Stability:

High-quality crane rail systems effectively absorb operational impacts, maintain proper straightness and levelness, and reduce vibration and dynamic load levels. This minimizes stress concentration in structural components and significantly extends the safe service life of the entire crane system.

Performance Advantages of HSCRANE Crane Rail Systems

As a professional provider of lifting equipment solutions, HSCRANE has extensive experience and mature technologies in the design and integration of crane rail systems. Its rail solutions not only meet the demands of high loads and high operating frequency in industrial environments, but also deliver outstanding stability and ease of maintenance.

• High load-bearing capacity:

HSCRANE crane rail systems use high-strength steel and optimized rail cross-section designs. They can reliably withstand crane self-weight and rated loads while coping with impact forces and horizontal loads generated during operation. This makes them especially suitable for heavy-duty and high-frequency applications.

• Excellent operational stability:

Precision rail manufacturing and installation processes ensure strict control of straightness and elevation accuracy. This effectively reduces vibration and travel deviation, allowing cranes to operate smoothly and efficiently during material handling, loading/unloading, and lifting operations.

• Installation- and maintenance-friendly design:

With a scientific structural layout and modular design, HSCRANE crane rail systems allow fast installation and commissioning. Over long-term operation, they reduce adjustment needs and maintenance costs while lowering failure rates.

How to Select the Right Crane Rail Solution Based on Operating Conditions

In real projects, crane rail selection should be matched to crane type, load class, operating environment, and future expansion requirements.

|

Crane Type |

Load Class / Frequency |

Operating Environment |

Future Expansion |

Recommended Rail Type |

Rail Structure & Installation Key Points |

Key Selection Control Factors |

| Overhead crane | Light duty ≤10 t, low frequency | Indoor workshop | No | Standard steel rail | Steel beams or corbels, clamp plate fixing | Control straightness, prevent skewing |

| Overhead crane | Medium duty 10–50 t, medium–high frequency | Indoor workshop | Possible | Reinforced steel rail | Elastic pads + clamp plate system | Verify single-wheel load and fatigue |

| Overhead crane | Heavy duty ≥75 t, high frequency | Indoor or semi-outdoor | Recommended | Dedicated crane rail | Rigid foundation + dedicated clamp plates | Contact stress, rail service life |

| Heavy-duty / metallurgical crane | Ultra-heavy load, high impact | Steel mills, metallurgical plants | Usually no | Heavy-duty crane rail | Welded or heavy clamp plate fixing | Impact loads and stability |

| Gantry crane | Medium to heavy duty, medium–high frequency | Outdoor yards | Yes | Dedicated crane rail | Concrete foundation with expansion joints | Ground settlement and rail gauge |

| Semi-gantry crane | Medium duty, medium frequency | Workshop + ground | Yes | Crane rail | One side steel beam, one side foundation | Uneven settlement verification |

| Port gantry / yard cranes | Heavy duty, high frequency | Ports, terminals | Yes | High-strength crane rail | Anti-corrosion treatment, heavy foundation | Salt spray corrosion, fatigue |

| Quay cranes / shipyard cranes | Ultra-heavy duty, continuous operation | Ports, shipyards | Limited | Ultra-heavy crane rail | High-precision installation, welded joints | Extreme wheel loads, safety redundancy |

| Automated crane systems | Medium to heavy duty, high frequency | Indoor / ports | Automation upgrades | Precision-ground crane rail | High-precision rail gauge | Positioning accuracy, smooth travel |

In lifting systems, crane rails are often regarded as auxiliary components, yet they actually carry the core responsibility for load bearing, safety, and service life. Whether the rail selection is appropriate directly affects crane travel stability, structural stress distribution, and long-term maintenance costs.

Ignoring differences in operating conditions, load characteristics, and environmental factors often leads to misalignment, abnormal wear, or even serious safety hazards over time. Only by adopting a system-oriented approach—scientific selection during the design stage, strict accuracy control during installation, and regular inspection and maintenance during operation—can the full performance value of lifting equipment be realized.

Treating the crane rail as the primary foundation of the lifting system is not only a responsibility to the equipment itself, but also a long-term guarantee for production efficiency and personnel safety.

Contact HSCRANE to obtain the most suitable crane rail solution for your specific project conditions, ensuring every lift is stable, reliable, and durable over the long term.

Want to fundamentally reduce crane skewing and rail wear? Proper selection and guidance design of crane wheels are also critical to long-term rail system stability:

How to Choose the Right Crane Wheels for Overhead Cranes: A Complete Selection Guide

FAQ

Q1: What is the difference between crane rails and railway rails?

A1: Crane rails and railway rails differ fundamentally in loading conditions and design objectives. Crane rails mainly withstand high wheel loads, low travel speeds, frequent starts/stops, and impact loads, emphasizing load capacity, wear resistance, and fatigue strength. Railway rails focus more on continuous smoothness and track continuity for high-speed train operation. Therefore, under heavy-duty and high-frequency lifting conditions, dedicated crane rails are usually required instead of standard railway rails.

Q2: How often should crane rails be inspected?

A2: Inspection intervals depend on operating frequency and load severity. General recommendations include:

• Daily inspection: Check for obvious wear, looseness, and abnormal noise

• Periodic inspection (every 3–6 months): Measure rail gauge, straightness, and fastener condition

• Annual system inspection: Focus on rail wear, foundation settlement, and overall alignment accuracy

Q3: Why do crane wheels wear out quickly?

A3: Rapid wheel wear is usually not caused by a single factor, but by system-level issues, such as:

• Excessive deviation in rail straightness or rail gauge

• Mismatch between rail profile and wheel type

• Long-term crane skewing or rail gnawing

• Uneven rail wear or foundation settlement

Q4: What is the most critical parameter in crane rail selection?

A4: The most critical parameter is not the rated lifting capacity, but the maximum single-wheel load, which must be verified together with the duty class (A3–A8), operating frequency, and impact loads. Ignoring wheel loads can easily lead to premature rail fatigue or deformation.

Q5: If crane skewing or rail gnawing occurs, is it always a rail problem?

A5: Not necessarily. Skewing or rail gnawing may result from rail installation accuracy issues, but can also be related to wheel taper, wheel gauge settings, end beam deformation, or installation errors. In practice, a comprehensive investigation should be carried out from three perspectives: the rail system, the wheels, and the overall crane structure.