Abstract:

Crane limit switches are critical components of crane safety control systems. They play a vital role in ensuring safe equipment operation and personnel protection. This article systematically explains the definition, working principles, and functions of crane limit switches. It focuses on common types such as current overload limits, height limits, overload limits, and cross limits. Their functional characteristics are analyzed in detail. The article also examines key factors affecting limit switch quantity configuration. These factors include crane type, duty classification, operating environment, and safety standards. The importance of coordinated multi-limit protection is emphasized. This improves operational stability and system reliability. Daily maintenance points and common troubleshooting methods are introduced. Combined with HSCRANE engineering practice, advantages in safety design, system integration, and customized configuration are demonstrated.

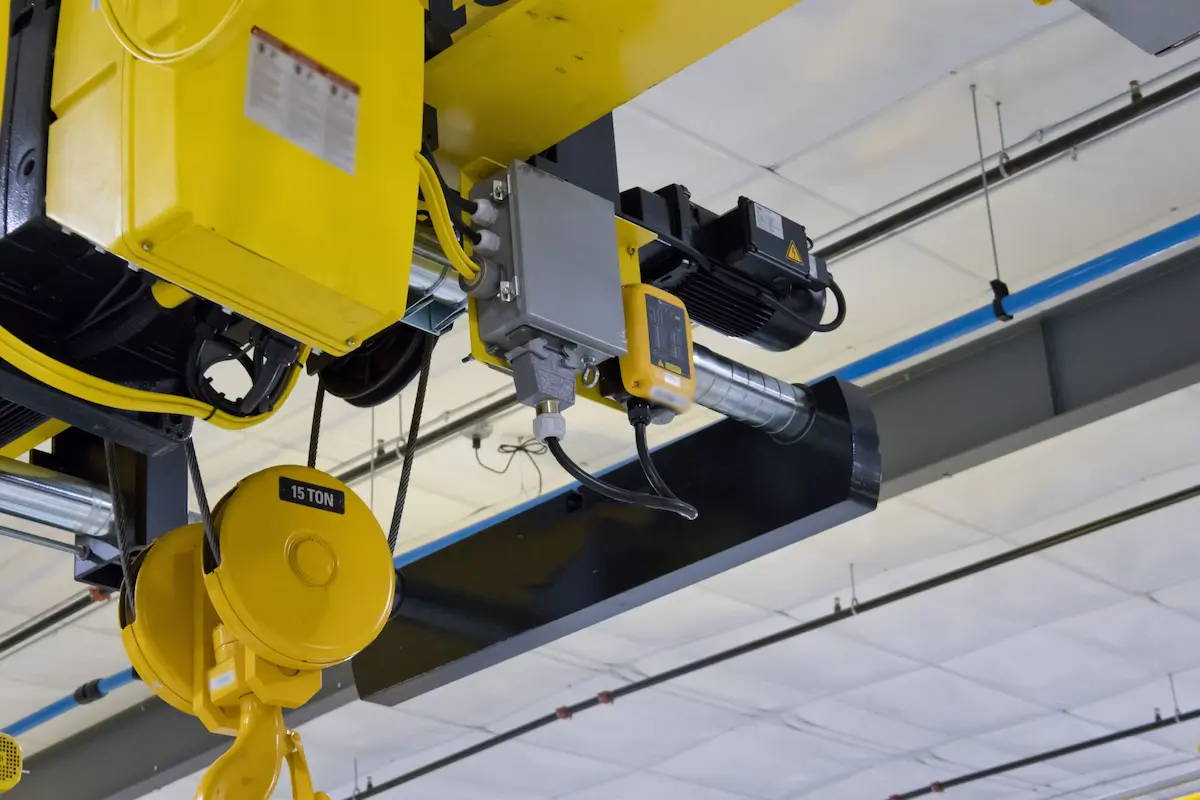

Cranes operating under high-intensity and continuous conditions place extremely high demands on safety control systems. As critical safety protection devices, crane limit switches occupy a core position within crane safety systems. By monitoring lifting load, travel range, and operating status in real time, limit switches effectively prevent overload, overtravel, and misoperation risks. They ensure stable crane operation and reduce equipment failure rates. Reliable protection is provided for operators and jobsite safety.

What Is a Crane Limit Switch?

In modern crane design, limit switches are indispensable safety configurations. They are also key components for meeting international and industry safety standards.

Definition of a Crane Limit Switch:

A crane limit switch is a position or status detection device installed at critical crane motion components. Through mechanical triggering, electrical sensing, or electronic signal acquisition, it limits and controls operating travel, lifting load, and motor load parameters.

Basic Working Principle:

When a crane mechanism reaches a preset limit position or an abnormal operating condition, the limit switch is triggered. It immediately outputs a signal to the control system.

Functions of Limit Switches in Crane Electrical Control Systems:

✓Prevent serious accidents such as overhoisting, derailment, and overwinding

✓Reduce abnormal wear of motors, gearboxes, and wire ropes

✓Lower safety risks caused by misoperation

✓Extend service life of the crane and critical components

Analysis of Common Crane Limit Switch Types and Functions

Based on crane structure, operating conditions, and safety class requirements, different limit switches are applied at key lifting, traveling, and control positions. Various limit switches work together to form a complete and reliable safety protection system. The following provides a detailed analysis of common crane limit switch types.

Current Overload Limit Switch

Working Principle and Detection Method

Current overload limit switches judge operating status by monitoring motor current in real time. During lifting or traveling, excessive load, mechanical jamming, or electrical faults may increase motor current beyond safe values. The limit device activates immediately.

This limit type is usually integrated with motor protection systems, inverters, or electrical control cabinets. It enables rapid response to abnormal current conditions.

Main Functions

Real-time detection of motor current changes

Prevent long-term motor overload operation

Avoid motor overheating, burnout, and electrical system damage

Applicable Operating Conditions and Equipment Types

Lifting mechanisms and electric hoists

Cranes with high duty cycles and frequent load variations

Automated or intelligent cranes requiring enhanced motor protection

Hoisting Height Limit Switch

Installation Location and Structural Forms

Hoisting height limit switches are typically installed near lifting mechanisms or winch systems. Mechanical contacts, cam mechanisms, or encoders precisely control upper and lower hook limits.

According to safety level requirements, configurations generally include:

✓Upper travel limit

✓Lower travel limit

✓Dual upper limit (working limit plus safety limit)

Main Functions

Limit hook upper and lower extreme positions

Prevent hook overhoisting

Prevent rope overwinding, rope breakage, and drum damage

Common Application Equipment

Overhead cranes

Gantry cranes

Port cranes

Metallurgical cranes

Electric hoists and special lifting equipment

Overload Limit Switch

Overload limit switches monitor actual lifting loads. Based on structure and technology, they are classified as:

✓Mechanical overload limits using springs and levers

✓Electronic overload limits using sensors, load cells, and control systems

Electronic overload limits offer higher accuracy, faster response, and system integration capability. They have become standard configurations in modern cranes.

Main Functions

Real-time monitoring of lifting load changes

Issue alarms during overload conditions

Automatically cut off lifting actions to prevent further hoisting

Significance for Equipment Life and Operational Safety

Prevent structural fatigue caused by long-term overload

Reduce wear of steel structures, wire ropes, and hoisting mechanisms

Lower risks of major safety accidents

Cross Limit Switch

Working Logic and Control Method

Cross limit switches are used for coordinated multi-mechanism operation control. Logical judgment and electrical interlocking restrict simultaneous actions under specific conditions.

Main Functions

Prevent conflicts from simultaneous mechanism movements

Avoid collisions between cranes or crane mechanisms

Reduce safety hazards caused by misoperation

Typical Application Scenarios

Multi-girder overhead cranes

Multi-trolley crane systems

Automated storage and intelligent logistics lifting equipment

Operating conditions with limited space or complex travel paths

Factors Determining the Number of Crane Limit Switches

The number of crane limit switches is not fixed. It requires comprehensive evaluation based on crane type, operating conditions, safety level, and project standards. Reasonable limit switch configuration meets regulatory requirements and significantly improves operational safety and system reliability.

|

Determining Factor |

Specific Category / Condition |

Impact on Limit Switch Quantity |

Typical Configuration Description |

| Crane type | Overhead crane | Medium | Typically equipped with hoisting height, overload, current overload, and travel limit switches |

| Gantry crane | Higher | Additional long travel limits, wind protection, and anti-collision limits are required | |

| Port and special cranes | High | Multiple limit systems are required, including dual height limits and interlock limits | |

| Duty class and usage frequency | A3–A4 (light / medium duty) | Lower | Basic safety limit configuration is sufficient |

| A5–A6 (heavy duty) | Medium to high | Redundant limits are added to improve system reliability | |

| A7–A8 (extra heavy / continuous duty) | High | Dual or multiple limit combinations are commonly applied | |

| Lifting height | Lower lifting height | Fewer | A single height limit meets basic safety requirements |

| Greater lifting height | More | Working limit plus safety limit prevent overhoisting accidents | |

| Travel distance | Short travel | Fewer | Simple travel limit configuration is sufficient |

| Long travel | More | End limits, buffers, and anti-collision limits are added | |

| Number of mechanisms | Single mechanism | Fewer | Independent limit control is applied |

| Multiple mechanisms | More | Each mechanism requires independent and cross limit protection | |

| Operating environment | High-temperature environment | More | High-temperature resistant or redundant limits are required |

| Dusty environment | More | Sealed limit switches with backup protection are recommended | |

| Corrosive environment | More | Anti-corrosion limit switches reduce failure risks | |

| Safety regulations and standards | Domestic standards (GB/T) | Basic | Meets minimum legal safety requirements |

| International standards (FEM / ISO / EN) | Higher | Dual limits or redundant designs are commonly required | |

| Project-specific safety standards | Variable | Limit quantity is customized based on client requirements | |

| Customization or complex conditions | Standard conditions | Fewer | Configured according to mature standard solutions |

| Customized design | More | Additional limits based on conditions and operating logic | |

| Complex operating conditions | High | Multiple cross limits and interlock protections are required |

Reasonable and scientific determination of limit switch quantity is critical. It ensures long-term crane safety, project acceptance compliance, and reduced maintenance risks.

Coordinated Protection of Different Crane Limit Switches

✓Complete safety protection system through multiple limit switches: Height, overload, and current overload limits work together. They provide multi-level monitoring of position, load, and operating status. This forms a comprehensive safety protection system.

✓Improved operational stability and reliability: Different limit switches complement and verify each other. This prevents risks caused by single protection failure. It reduces misoperation and abnormal equipment impact. Long-term stability and reliability are significantly improved.

✓Essential configuration for international and industry safety standards: Coordinated multi-limit protection is required by GB, FEM, and ISO standards. It is also a basic requirement for high-safety cranes and international projects.

Crane Limit Switch Maintenance and Troubleshooting Techniques

Standardized maintenance and timely troubleshooting are essential for long-term stable limit switch operation. Scientific inspections and proper corrective actions effectively reduce failure risks. They ensure safe and reliable crane operation.

Daily Maintenance Key Points

✓Regularly inspect limit switch installation positions: Confirm secure installation and accurate positioning. Prevent displacement caused by vibration, impact, or long-term operation.

✓Ensure sensitive contacts and reliable actuation: Check fast response and proper reset during triggering. Prevent wear, spring fatigue, or dust causing malfunction.

✓Inspect wiring connections and protection conditions: Check terminal tightness, insulation integrity, and protection ratings. Prevent electrical failures from water, dust, or aging.

Common Faults and Cause Analysis

✓Limit switch failure: Usually caused by misalignment, mechanical damage, or internal contact burnout. This may result in overtravel and serious safety risks.

✓False operation or frequent tripping: Often related to poor contact, electrical interference, or improper setting values. This affects normal operating efficiency.

✓Abnormal signals or slow response: Possibly caused by wiring aging, sensor degradation, or control mismatch. Timely inspection prevents potential hazards.

Basic Troubleshooting Recommendations

✓Calibrate or adjust limit positions: Recalibrate trigger points according to technical parameters. Ensure actions meet design requirements.

✓Replace damaged components: Worn, aged, or failed limit switches should be replaced promptly. Avoid operating with known defects.

✓Inspection by qualified professionals: Electrical or safety-related adjustments require certified technical personnel. This ensures maintenance quality and operational safety.

HSCRANE Crane Limit Switches and System Configuration Advantages

✓Strict safety design and quality control: HSCRANE crane limit switches strictly follows domestic and international safety standards. Safety components undergo multiple verifications and tests.

✓Customized safety solutions: HSCRANE provides flexible limit configurations for different conditions. Safety functions precisely match actual application requirements.

✓System integration and stable operation: Limit switches integrate closely with electrical control systems. Coordinated mechanism operation reduces misoperation risks.

✓Extensive global project experience: HSCRANE delivers compliant safety solutions worldwide. Configurations meet local standards and ensure long-term reliability.

Crane limit switches are core components of crane safety control systems. Proper configuration directly affects safety, stability, and service life. Scientific selection and coordinated multi-limit protection prevent overtravel, overload, and misoperation risks. Reliable protection is ensured under complex operating conditions.

Welcome to contact HSCRANE for professional limit switch configurations. We provide complete crane safety solutions for safe, efficient, and stable operation.

If you wish to learn about anti-collision systems, please read Crane Anti-Collision System Solutions: Enhancing Equipment Reliability and Operational Safety. This provides comprehensive safety guidance.

FAQ

Q1: Are crane limit switches mandatory for all lifting equipment?

A1: Yes. Limit switches are basic safety configurations for almost all cranes. They prevent overtravel, overload, and misoperation risks.

Q2: Why do cranes require multiple types of limit switches?

A2: Different limits address position, load, current, and interlocking risks. Coordinated protection forms a complete safety system.

Q3: Can limit switches replace operator safety judgment?

A3: No. Limit switches support safety protection. Proper operation remains essential for optimal safety performance.

Q4: How often should limit switches be inspected or maintained?

A4: They should be included in daily and periodic inspections. High-frequency or harsh conditions require increased inspection frequency.

Q5: Do limit switch requirements differ by country or project?

A5: Yes. Standards vary by country and industry. International projects often require higher safety redundancy.

Q6: Can HSCRANE provide customized limit and safety solutions?

A6: Yes. HSCRANE offers customized limit switch and complete safety solutions. Configurations match project conditions and standards.

This document is for reference only. Specific operations must strictly comply with local laws and regulations and equipment manuals.