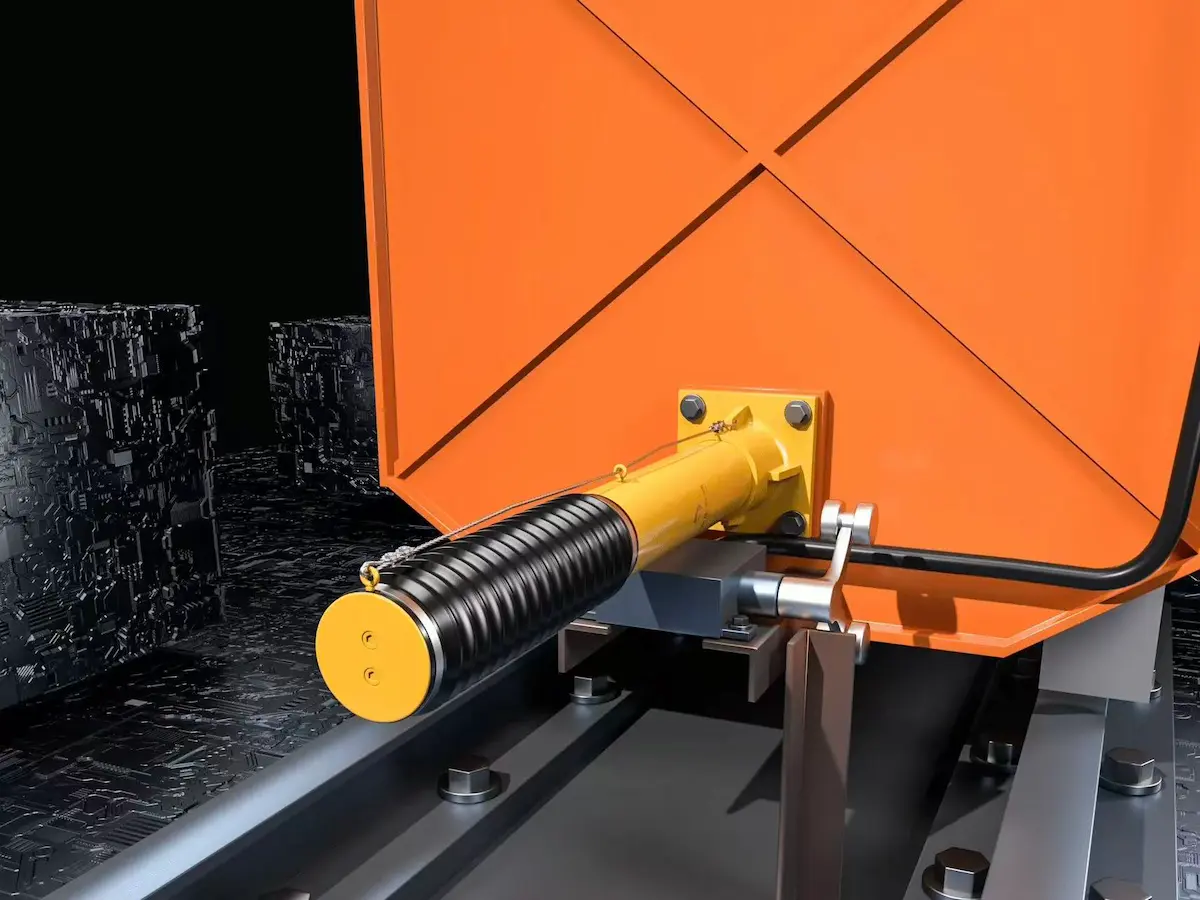

Crane buffers are safety devices installed at crane travel endpoints to absorb collision energy and reduce impact forces. They prevent hard impacts and protect structural components, ensuring smooth crane operation. Buffers are essential for bridge, gantry, and suspension cranes. The following sections explain types, working principles, functions, and selection guidance.

What Is a Crane Buffer?

Definition and working principle of crane buffer

- Crane Buffer Definition: A crane buffer is a safety device used to absorb and dissipate kinetic energy at the travel end. Its main function is to decelerate the crane or trolley before reaching the track end, preventing severe collision.

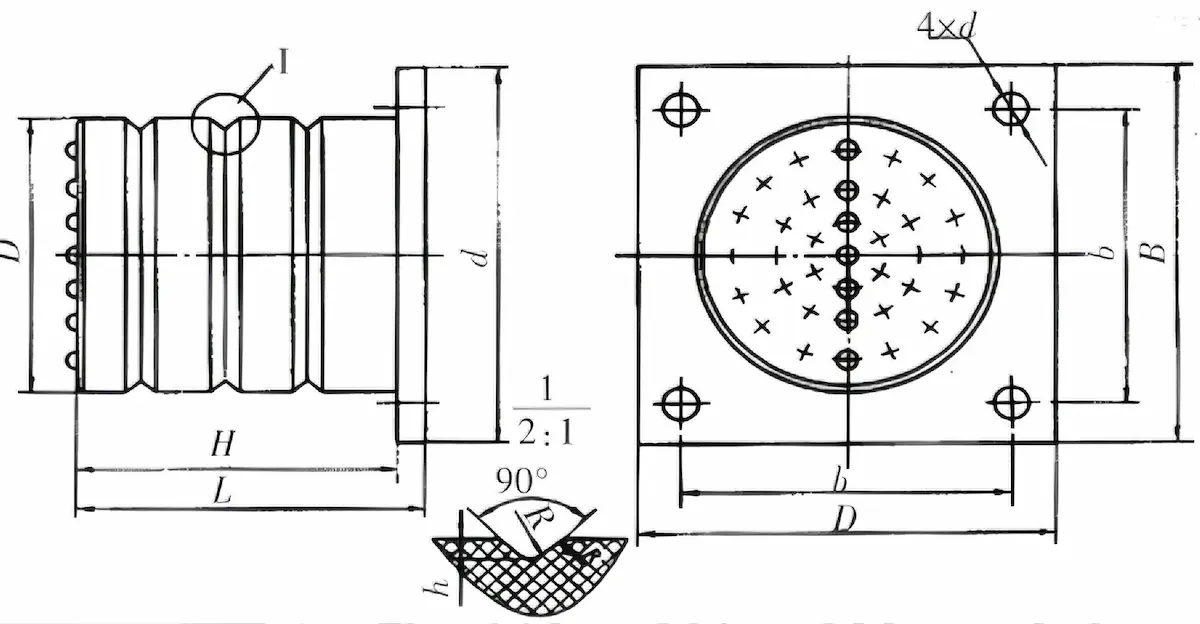

- Working Principle of Crane Buffer: The buffer is usually installed at both ends of the end beam or at anti-collision points, opposite the rail stop block. When the crane reaches its limit, the body contacts the buffer. The internal elastic or hydraulic elements absorb the kinetic energy in a short time. This energy is converted into heat or elastic deformation, reducing impact force. The process ensures safe and stable crane operation.

Main Functions of Crane Buffer

- Absorbing kinetic energy at travel ends: When the crane or trolley reaches the rail end, the buffer absorbs and dissipates kinetic energy through elastic or hydraulic damping, preventing strong impacts.

- Preventing structural impact and damage: The buffer effectively reduces collision force, preventing deformation or damage to end beams, girders, and joints.

- Protecting key components: It reduces mechanical wear and maintenance frequency, lowering maintenance costs and unplanned downtime.

- Improving operational safety and comfort: It ensures smooth deceleration near limit positions, avoids vibration, and enhances operational safety and comfort.

Types of Crane Buffers

Crane buffers can be classified by structure and energy absorption method. Below are the common types and their application analysis:

|

Buffer Type |

Working Principle |

Main Advantages |

Application Scenarios |

Key Features |

Picture example |

|

Polyurethane Buffer |

Absorbs impact energy through the high elasticity and deformation of polyurethane, converting kinetic energy into heat. | High energy absorption, excellent damping, easy maintenance, long service life. | Bridge cranes, gantry cranes, trolleys, low-speed elevators. | Compact structure, cost-effective, widely used in industrial workshops. | |

|

Hydraulic Buffer |

Converts kinetic energy into hydraulic and thermal energy through throttled fluid damping during travel. | Strong energy absorption, stable performance, no special environmental requirements, full recovery after unloading. | Heavy-duty cranes, port machinery, elevators. | High-performance buffer, suitable for heavy and high-speed equipment. | |

|

Spring Buffer |

Uses elastic deformation of coil springs to absorb part of the impact energy. | Heat- and corrosion-resistant, no aging failure, stable operation. | Heavy cranes, port machinery, mining equipment. | Limited energy absorption, strong rebound, suitable for general conditions. | |

|

Rubber Buffer |

Absorbs partial impact energy through the elastic deformation of rubber material. | Low cost, simple structure, quick installation; soft collision, no noise or sparks, suitable for explosion-proof areas. | Light-duty cranes, trolley limit stops, low-speed devices. | Ideal for light loads and low frequency, requires regular replacement due to aging. | |

|

Composite Buffer |

Combines multiple energy absorption methods such as spring, polyurethane, or hydraulic damping for staged buffering. | Wide energy absorption range, excellent damping performance, adaptable to complex conditions. | High-safety industries such as metallurgy, nuclear power, and port machinery. | Multi-stage absorption, stable performance, ideal for harsh environments. | |

|

Damping Buffer |

Uses damping materials or viscous fluids to control impact velocity and extend buffering time. | Smooth energy absorption, minimal vibration, no strong rebound. | Precision handling vehicles, automated workshops. | High stability and comfort, protects equipment from vibration. | |

|

Gas-Hydraulic Buffer |

Combines gas compression and hydraulic throttling for dual energy absorption. | High energy efficiency, smooth buffering, wide load adaptability. | Port cranes, container cranes, heavy-duty specialized equipment. | Best overall performance, suitable for high-speed, heavy-load, and high-end systems. |

How to Choose the Right Crane Buffer

Crane buffers are key safety components that absorb kinetic energy at crane travel ends. Proper selection prevents rigid collisions, structural damage, and safety risks. Selection should consider equipment conditions, crane type, and international standards.

Match energy absorption to operating conditions

- Operating conditions determine buffer type. Focus on lifting capacity, speed, kinetic energy, and space.

- Low-speed, light-load conditions: Prefer polyurethane or rubber buffers. Compact, easy to install, elastic deformation absorbs energy. Cost-effective, low maintenance, suitable for light indoor handling.

- Medium/high-speed or heavy-load conditions: Recommend hydraulic, gas-hydraulic, or composite buffers. Hydraulic buffers use oil throttling for smooth energy absorption and stable maximum force. Gas-hydraulic buffers combine gas elasticity and hydraulic damping to avoid sudden impact damage.

- Limited installation space: Choose slim or compact buffers for effective cushioning in tight areas.

Determine buffer model by crane type

- Bridge crane/single-girder crane: Moderate lifting capacity and speed. Use polyurethane or small hydraulic buffers.

- Gantry crane/double-girder crane: High lifting capacity, often outdoors; use hydraulic or gas-hydraulic buffers.

- Light-duty crane: Economical and practical; spring or rubber buffers are sufficient.

Refer to international standards

- Standards such as FEM, ISO, CMAA require buffers to absorb all kinetic energy at rated speed. Maximum buffer force must remain within structural limits.

- Buffers must work with crane limit devices and be inspected regularly for energy absorption and deformation.

Maintenance Tips for Crane Buffers

Crane buffers endure frequent impacts and vibrations. Regular maintenance ensures safety and reliability.

- Regular inspection of appearance and performance: Check for wear, cracks, deformation, or aging. Observe for oil leaks, looseness, or abnormal noises. Replace damaged buffers immediately to prevent failure.

- Hydraulic buffer maintenance: Inspect seals, oil levels, and stroke regularly. Keep the surface clean to prevent dust or corrosion ingress. Replace or repair if leakage, reduced energy absorption, or uneven action occurs.

- Alignment and fastening checks: Ensure buffers are coaxially aligned with rail stop blocks. Verify contact surfaces are flat to avoid uneven impact. Inspect base and bolts for tightness; prevent loosening or misalignment.

- Maintaining buffer integrity and proper installation prevents end collisions. Include buffer checks in routine inspections and annual maintenance schedules.

Crane buffers play a key role in safe crane operation and structural longevity. They effectively absorb end-of-travel impact energy, preventing machine damage. Buffers also protect operators and the surrounding environment. Selecting high-quality buffers that match operating conditions ensures long-term system stability.

Contact a professional manufacturer to choose suitable buffer solutions. Customized solutions are available for different lifting capacities, speeds, and installation requirements. For more details and selection guidance, visit HSCRANE’s crane buffer product page.