A European-style electric wire rope hoist refers to a hoist designed in accordance with European FEM standards.Compared with traditional electric hoists, it features a modern appearance and easier, more convenient operation.Its advanced design concept also better meets requirements for low noise, energy saving, and environmental protection.

European-Style Electric Wire Rope Hoist: Technical Parameters, Advantages, and Market Prospects

- Technical Parameters

- Standards: FEM, DIN

- Lifting Capacity: 0.5–50 t

- Lifting Height: 6–30 m

- Duty Class: M5–M7

- Working Temperature: -20℃ to +40℃

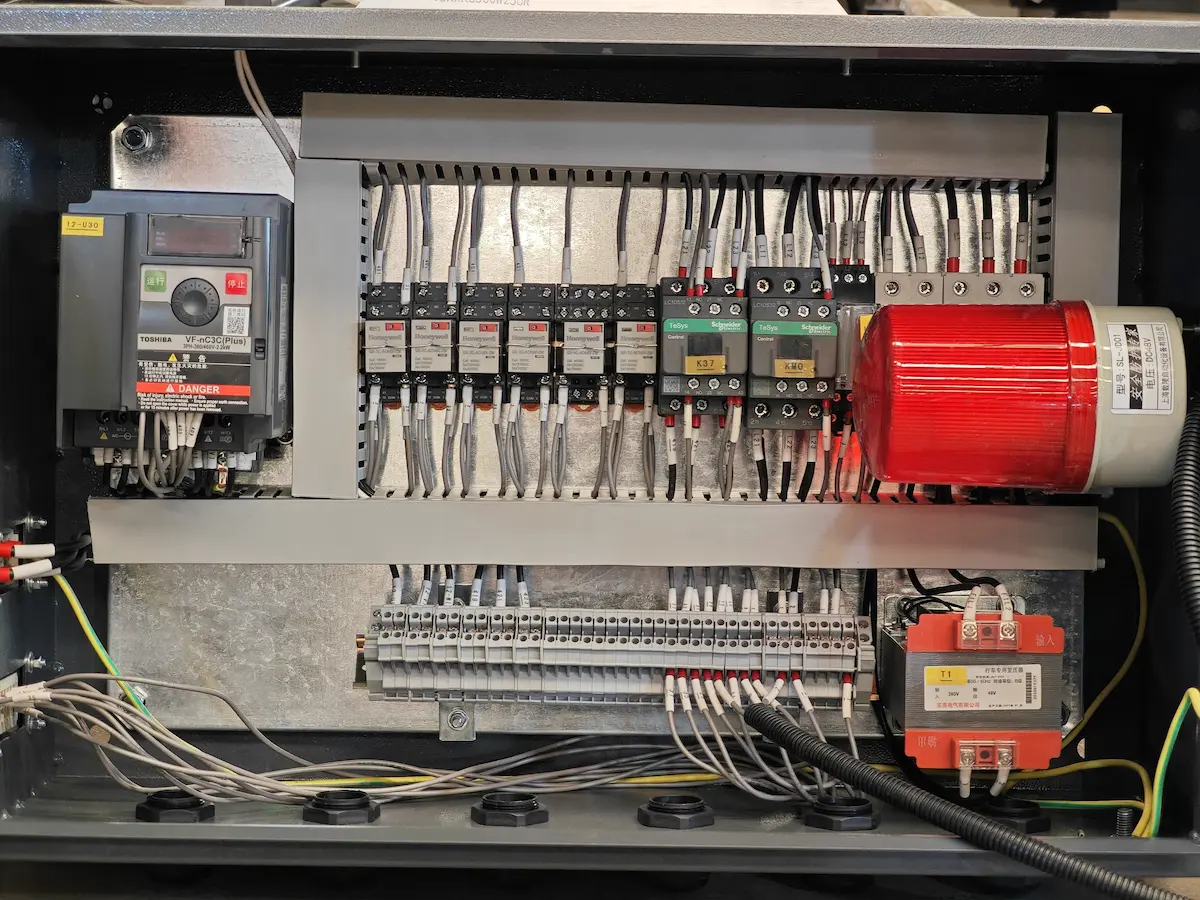

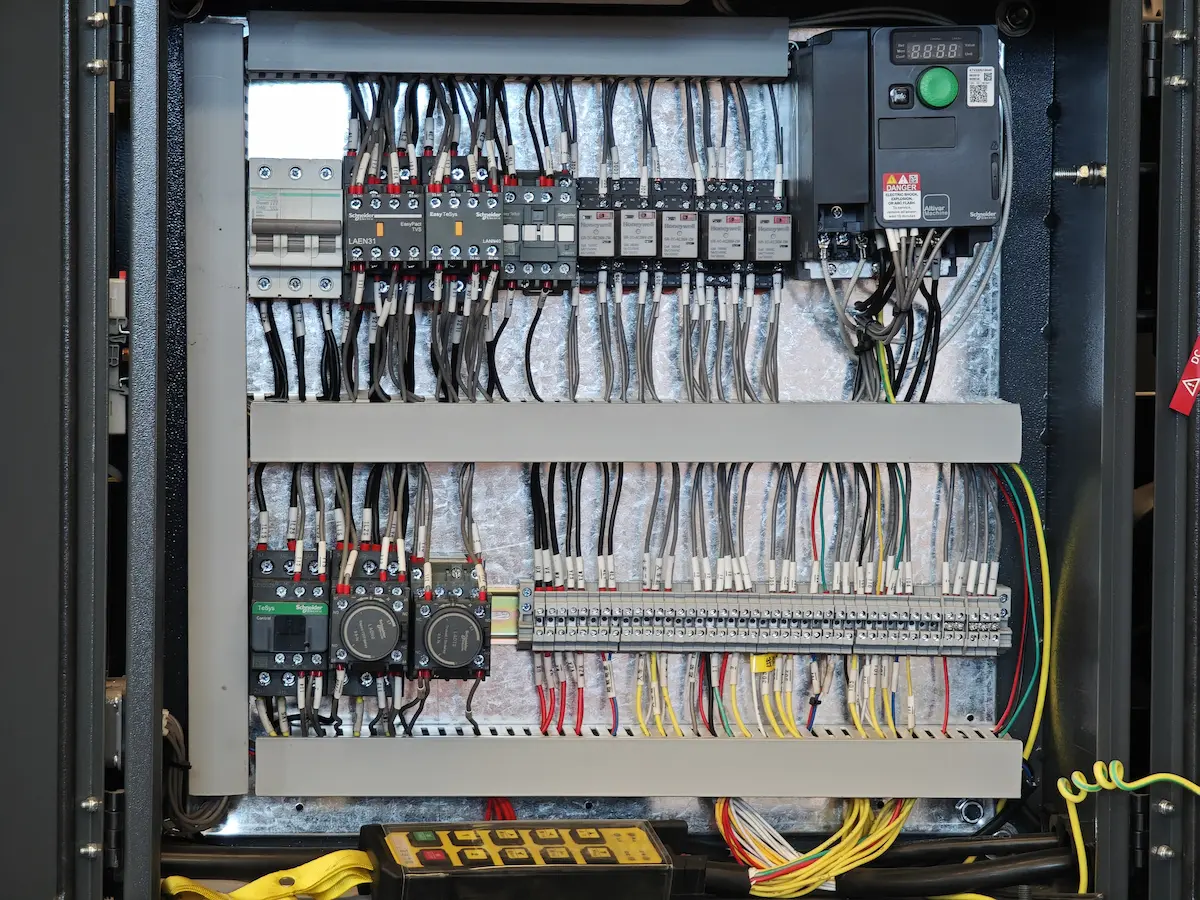

- Control Options: Pendant control / Remote control

- Operating Speed:

- Trolley: 0.5–20 m/min (variable frequency)

- Crane: 10–40 m/min (variable frequency)

Key Features

- Compact structure, small size, lightweight, reduced wheel load.

- Advanced welding technology for higher rigidity and lower wear.

- Small blind spots, wider working coverage.

- Energy-saving and high efficiency.

- Designed under FEM standards, offering user-friendly speed and motion control.

- Variable-speed operation for smoother lifting and traversing.

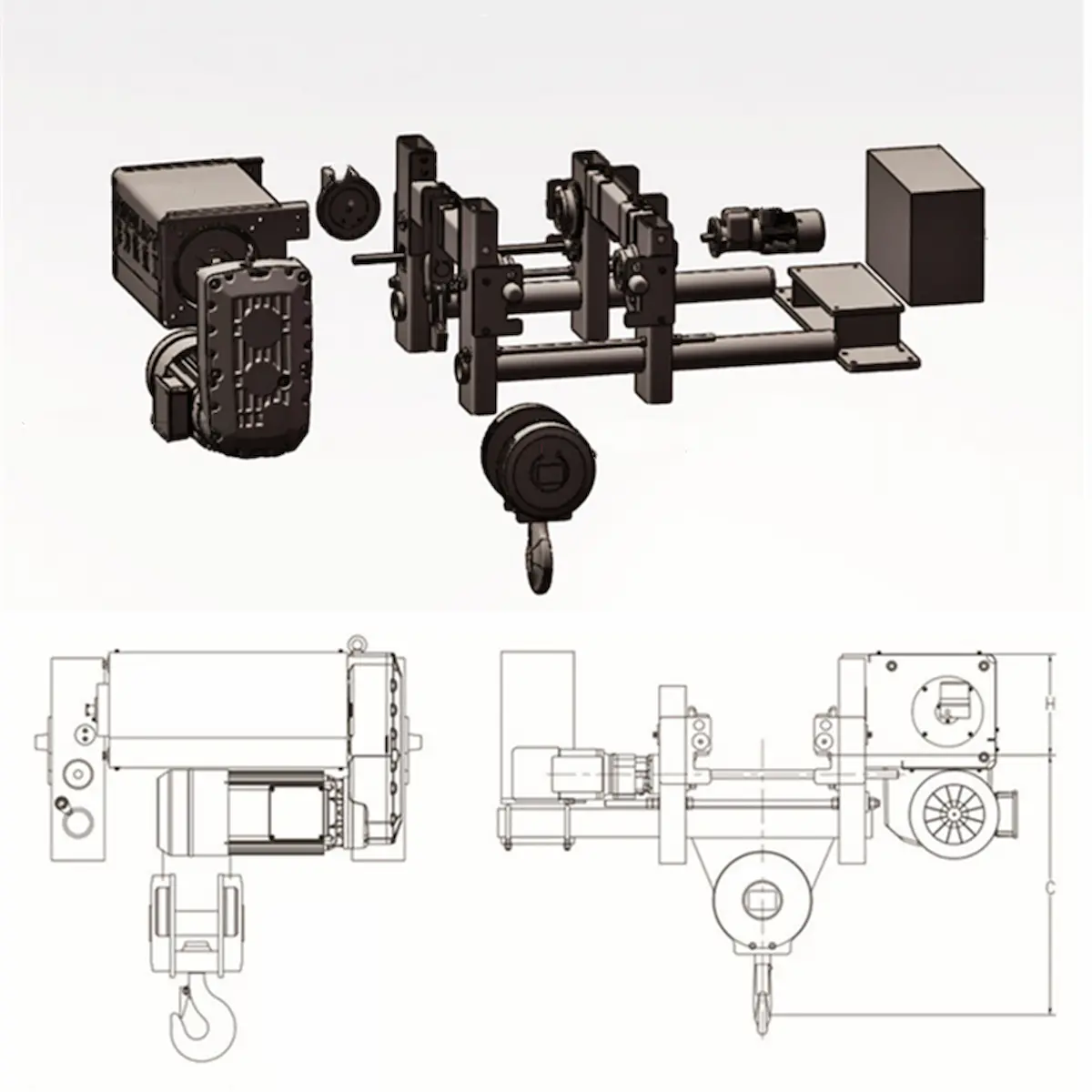

European gourd structure diagram

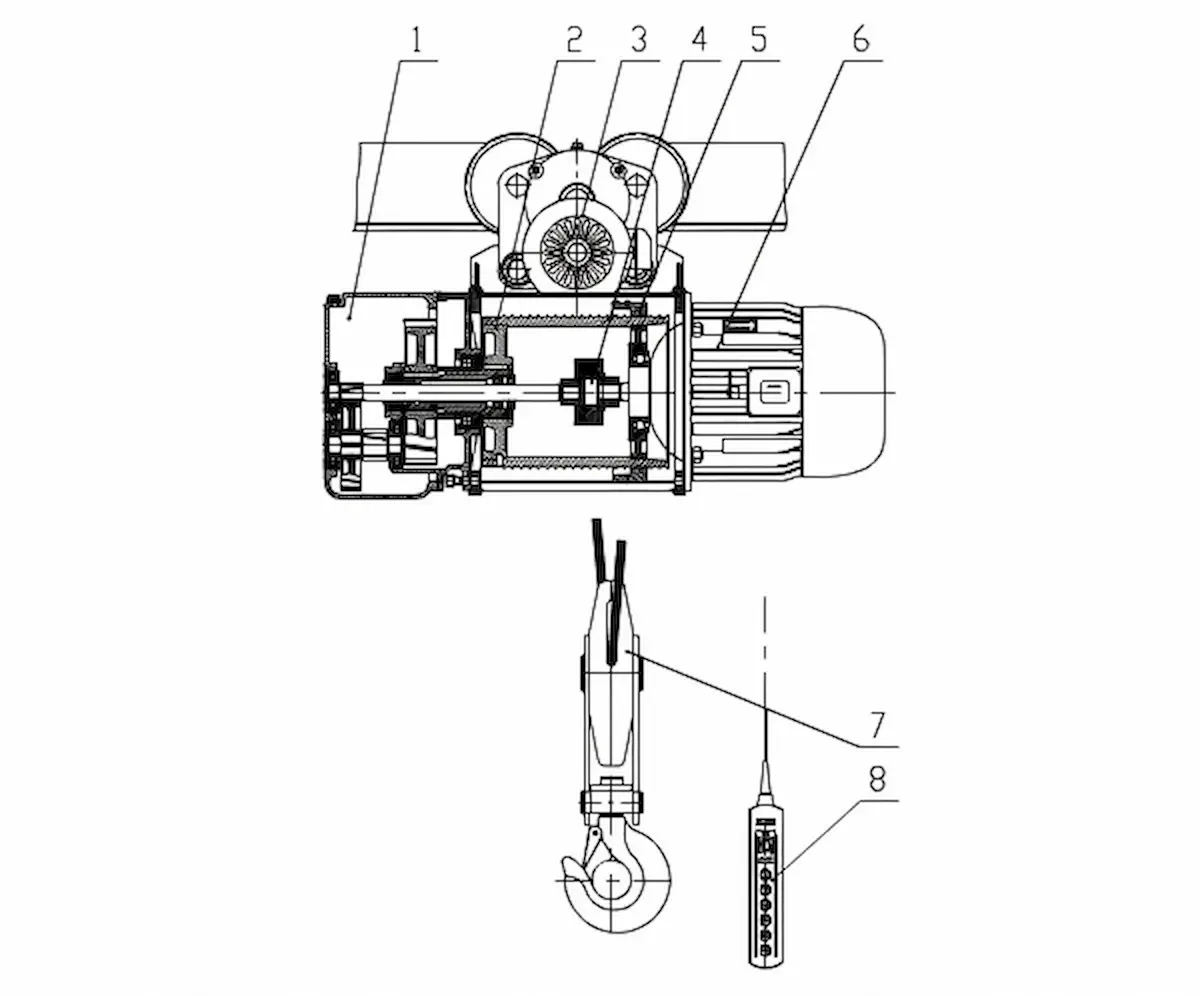

Traditional gourd structure diagram

Comparison with Traditional Hoists

|

Dimension |

Traditional Electric Hoist |

European-Style Electric Hoist |

| Structural Design | Motor and reducer separated, bulky | Motor and reducer integrated, 30–50% smaller |

| Transmission | Standard gears, ≤85% efficiency | Hardened helical gears, ≥96% efficiency (e.g., SEW reducer) |

| Lifting Motor | Three-phase asynchronous motor, high starting current | Permanent magnet or VFD motor, 25–40% energy saving |

European-style hoists show stronger performance, precision, and efficiency,making them the preferred choice for modern enterprises.

Application Scenarios

|

Scenario |

Load Range |

Technical Configuration |

Benefits |

|

Manufacturing Assembly |

5–20 t |

Dual-speed VFD + RFID positioning (≤±50 mm) | Quick setup, 40% shorter tool-change time |

|

Automated Warehousing |

1–10 t |

Low-headroom design + WMS integration | 40% increase in lifting height |

|

Ports & Shipyards |

10–50 t |

Anti-salt coating + weather-resistant wire rope (zinc ≥85 μm) | Withstands winds ≤25 m/s, longer anti-corrosion life |

|

Metallurgy & Energy |

32–100 t |

Explosion-proof (Ex d IMBT4) + heat-resistant rope (300℃) | 24/7 operation, 1.5× overload protection |

|

Precision Installation |

0.5–5 t |

Micro-speed control (0.1 m/min) + laser ranging | Semiconductor lifting, vibration ≤5 μm |

Why European-Style Hoists Have a Broader Market Outlook

With the growth of IoT and AI, European hoists are evolving toward intelligent systems.Equipped with IoT and 5G modules, they upload real-time operating data,support self-diagnosis, and enable predictive maintenance (e.g., bearing wear alerts).This prevents failures and reduces industrial risks.Through PLC programming, they can achieve unmanned material handling,as in smart warehouses, improving efficiency while cutting costs and risks.In the future, companies with strong R&D, scenario-based solutions,and global service networks will lead the market.Low-cost, price-driven manufacturers will gradually phase out.Relying on superior structure, versatile applications,and deep integration with intelligent technologies,European-style hoists will be your best partner for industrial production and material handling.

How to Choose the Right European Electric Wire Rope Hoist

Define Your Application Needs:

- Rated Lifting Capacity: Calculate based on the maximum daily load and allow a 10%–20% safety margin.

- Lifting Height: The distance from the ground to the upper limit position of the lifting device; customized options are available for special applications.

- Lifting Speed: Our engineers can recommend the most suitable speed according to your specific requirements.

Working Environment:

Operating Temperature: Standard European hoists are designed for -20℃ to +40℃. Special customization is required for extremely low or high temperatures.

Special Conditions:

- Explosion-proof applications (e.g., chemical plants): Choose explosion-proof hoists compliant with ATEX or IECEx standards.

- Dusty or humid environments: Select hoists with IP54 protection class or above.

- Corrosive environments (e.g., gas or marine conditions): Use hoists with stainless steel housings or anti-corrosion coating.

Operation Modes:

Installation Type:

- Fixed type → suitable for single-point lifting.

- Traveling type → works with single-girder or double-girder cranes for multi-point operations.

Control Method:

- Pendant control (wired) → economical and simple.

- Wireless remote control → flexible and safe, ideal for large spans or hazardous areas.

- Integrated control station → for centralized crane operation.

HSCRANE Heavy Industry Machinery Equipment Co., Ltd. was established in 1998 and has emerged as a leading manufacturer of lifting equipment for general industry.Over the years, our active participation in numerous large-scale road and bridge projects across China has enabled us to accumulate invaluable technical expertise and develop a highly proficient engineering and installation service team.