A winch lifts, lowers, or pulls heavy loads by winding wire rope or chain around a drum.Its power source—electric motor, hydraulic motor, or manual drive—rotates the drum for controlled movement.With a compact structure, flexible operation, and strong load capacity,the winch is widely used in construction, mining, ports, water projects, rescue, and industrial production.

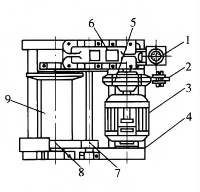

Main Components

A winch generally consists of the following core parts:

- Power Unit: Supplies driving force, such as electric motor, diesel engine, hydraulic motor, or manual drive.

- Drum: Winds the wire rope or chain; its diameter and rope capacity determine load and working range.

- Reduction Gearbox: Uses gears or worm drive to lower motor speed and increase output torque for smooth operation.

- Brake System: Provides emergency stop or load holding, including electromagnetic, hydraulic, or mechanical brakes.

- Control System: Features handles, remote devices, limit switches to prevent over-winding or slack, and overload protection.

- Frame and Base: Offer stable support to prevent displacement or tipping under heavy loads.

Working Principle

The winch operates through the following steps:

- Power Input: The motor or other power source starts and drives the reducer via coupling or belt.

- Torque Amplification: The reducer lowers speed and increases torque, giving the drum sufficient pulling force.

- Rope Winding: The drum rotates, winding or releasing wire rope or chain to lift, lower, or pull the load.

- Brake Control: When operation stops, the brake engages immediately to prevent load slip or loss of control.

Winch Classification

Winches can be classified by different standards.

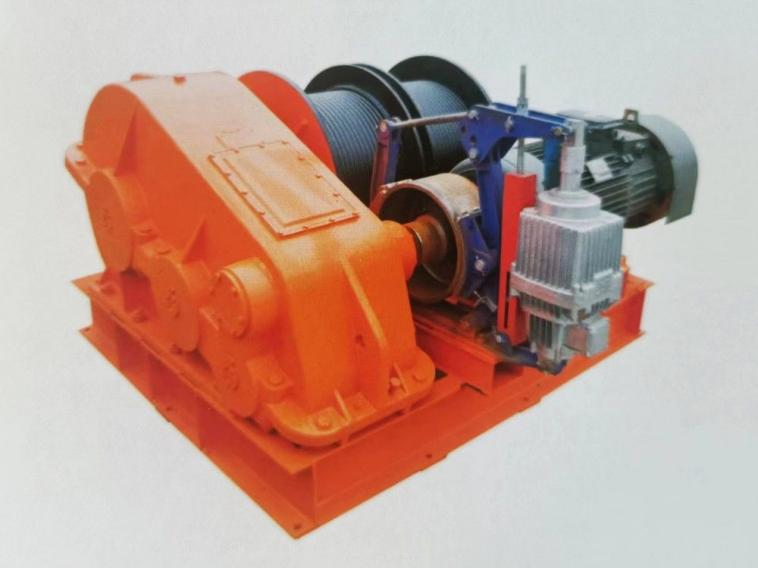

JM Electric Slow-Speed Winch

Used in lifting, bridge, and installation projects.This series uses a gear reducer for transmission.It handles hoisting, pulling, and dragging of heavy loads.Typical applications include large concrete, steel structures, and machinery installation or removal.Suitable for construction firms, mining areas, and factory civil works.

Working Principle:An electric motor drives a planetary or worm reducer to greatly lower output speed while increasing torque.The electric control system—using contactors or frequency converters—enables speed regulation, forward/reverse rotation, and braking.

JM type electric controlled slow speed winch technical parameter table

|

Type |

Rated pulling force(KN) |

Rated speed |

Rope capacity (m) |

Rope diameter |

Electromotor type |

Electromoor KN |

Overall dimension (m) |

Weight (kg) |

| JM1 | 10 | 15 | 100 | φ9.3 | Y112M-6 | 3 |

620×701×417 |

270 |

| JM1.6 | 16 | 16 | 150 | φ12.5 | Y132M₂-6 | 5.5 |

945×996×570 |

500 |

| JM2 | 20 | 16 | 150 | φ13 | Y160M-6 | 7.5 |

945×996×570 |

550 |

| JM3.2 | 32 | 9.5 | 150 | φ15.5 | YZR160M₂-6 | 7.5 |

1430×1160×910 |

1100 |

| JM3.2B | 32 | 12 | 195 | φ15.5 | YZR160M₂-6 | 7.5 |

1082×1014×610 |

536 |

| JM5 | 50 | 10 | 270 | φ21.5 | YZR160L-6 | 11 |

1235×1230×805 |

1560 |

| JM5B | 50 | 9.5 | 200 | φ21.5 | YZR160L-6 | 11 |

1620×1260×945 |

1800 |

| JM5C | 50 | 9.5 | 250 | φ21.5 | YZR160L-6 | 11 |

1235×1230×805 |

1800 |

| JM5D | 50 | 15 | 250 | φ21.5 | YZR180L-6 | 15 |

1235×1230×805 |

1850 |

| JM5E | 50 | 20 | 250 | φ21.5 | YZR200L-6 | 22 |

1235×1230×805 |

2000 |

| JM6 | 60 | 9.5 | 270 | φ24 | YZR180L-6 | 15 |

1235×1509×805 |

1800 |

| JM8 | 80 | 8 | 250 | φ26 | YZR180L-6 | 15 |

2090×1475×956 |

2900 |

| JM8B | 80 | 9.5 | 350 | φ26 | YZR180L-6 | 15 |

1075×1598×985 |

2650 |

We can design and manufacture non-standard products of various specifications according to user needs. The above parameters are subject to technical improvement without prior notice.

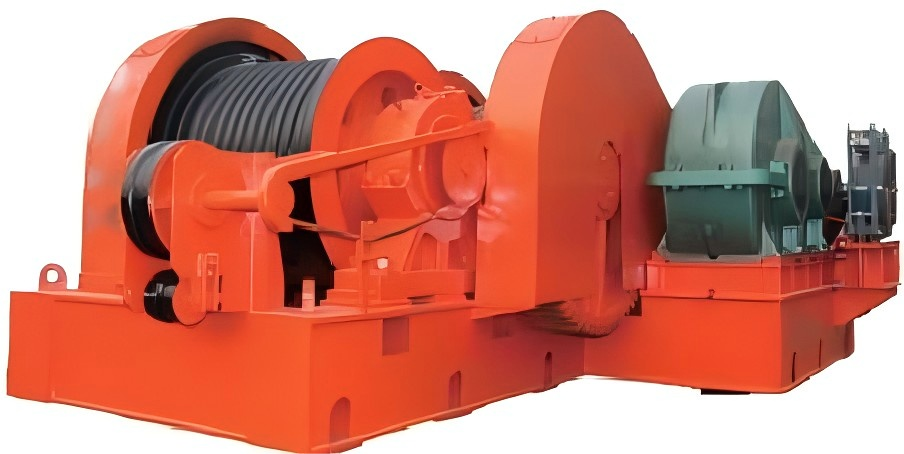

JM Electric Slow-Speed Heavy-Tonnage Winch

Designed for large and extra-large concrete, steel structures,and heavy machinery installation or removal.It features orderly rope arrangement and reliable lifting safety.Typical applications include bridges, ports, docks, and large factory or mining equipment projects.Working Principle:Similar to the standard JM type, but uses multi-stage gear reduction or a hydraulic motor combined with a reducer for higher torque.Equipped with reinforced drum, heavy-duty wire rope,and enhanced brakes such as hydraulic caliper systems.

JM type electric controlled slow speed large tonnage winch technical parameter table

|

Basic date Type |

Rated load (KN) |

Rated speed |

Rope capacity (m) |

Rope diameter |

Electromotor type |

Electromotor power (KN) |

Overall dimension (mm) |

Weight (kg) |

| JM10 | 100 | 8 | 170 | φ30 | YZR200L-6 |

22 |

2090×1475×956 |

3000 |

| JM10B | 100 | 9.5 | 250 | φ30 | YZR200L-6 |

22 |

1705×1598×985 |

3500 |

| JM12.5 | 125 | 8 | 300 | φ34 | YZR225M-6 |

30 |

2880×2200×1550 |

5000 |

| JM13.5 | 135 | 0-5 | 290 | φ28 | YZP225S-8 |

22 |

2990×2363×1650 |

6500 |

| JM16 | 160 | 10 | 500 | φ37 | YZR250M2-8 |

37 |

3750×2400×1850 |

8800 |

| JM20 | 200 | 10 | 600 | φ43 | YZR280S-8 |

45 |

3950×2560×1950 |

9900 |

| JM25 | 250 | 9 | 700 | φ48 | YZR280M-8 |

55 |

4350×2800×2030 |

13500 |

| JM32 | 320 | 9 | 700 | φ56 | YZR315S-8 |

75 |

4500×2850×2100 |

14800 |

| JM50 | 500 | 9 | 800 | φ65 | YZR315M-8 |

90 |

4930×3050×2250 |

19500 |

| JM65 | 650 | 10.5 | 3600 | φ64 | LA8315-8AB |

160 |

5900×4680×3200 |

46000 |

We can design and manufacture non-standard products of various specifications according to user needs. The above parameters are subject to technical improvement without prior notice.

JK Electric High-Speed Winch

Primarily used for material lifting, moving heavy loads,and as the main hoist on cranes, derricks, gantry frames, or lift trolleys.Suitable for construction, mining hoisting, factory civil works,and small equipment installation projects.

Working Principle:The motor drives the drum directly or through a low-stage gear reducer to achieve high line speed, typically above 30 m/min.The electric control system manages start/stop and speed adjustment,often paired with an electromagnetic brake for secure operation.

JK type electric controlled fast winch technical parameters

|

Basic date Type |

Rated load (KN) |

Rated speed |

Rope capacity (m) |

Rope diameter |

Electromotor type |

Electromotor power (KN) |

Overall dimension (mm) |

Weight (kg) |

|

JK0.5 |

5 |

22 |

190 |

φ7.7 |

Y100L-4 |

3 |

620×701×417 |

200 |

|

JK1 |

10 |

22 |

100 |

φ9.3 |

Y112M-4 |

4 |

620×701×417 |

300 |

|

JK1.6 |

16 |

24 |

150 |

φ12.5 |

Y132S-4 |

5.5 |

945×996×570 |

500 |

|

JK2 |

20 |

24 |

150 |

φ13 |

Y132M-4 |

7.5 |

945×996×570 |

550 |

|

JK3.2 |

32 |

25 |

290 |

φ15.5 |

YZR180L-6 |

15 |

1325×1335×840 |

1011 |

|

JK3.2B |

32 |

30 |

250 |

φ15.5 |

YZR200L-6 |

22 |

1900×1738×985 |

1500 |

|

JK5 |

50 |

30 |

300 |

φ21.5 |

YZR225M-6 |

30 |

1900×1620×985 |

2050 |

|

JK5B |

50 |

25 |

210 |

φ21.5 |

YZR225M-8 |

22 |

2250×2500×1300 |

2264 |

|

JK8 |

80 |

25 |

160 |

φ26 |

YZR280S-8 |

45 |

1533×1985×1045 |

3000 |

|

JK10 |

100 |

30 |

300 |

φ30 |

YZR315S-8 |

55 |

2250×2500×1300 |

5100 |

We can design and manufacture non-standard products of various specifications according to user needs. The above parameters are subject to technical improvement without prior notice.

JKL Hand-Controlled High-Speed Winch with Free-Release

Designed for vertical lifting of heavy loads at construction sites, factories, mines, and ports.Especially suitable for bridge, dock, and foundation projects requiring free-fall pile driving.Its key structural feature is a rotating main shaft (also called a spindle).

Working Principle:Based on the JK type, it adds a manual clutch and free-release mechanism.The operator uses a hand lever to release the brake, allowing controlled descent by load gravity. During this process, the motor may be powered off or idling.

JKL manual sled fast winch technical parameter table

|

Basic date Type |

Rated load (KN) |

Rated speed |

Rope capacity (m) |

Rope diameter |

Elctromotor type |

Electromotor power (KN) |

Overall dimension (mm) |

Weight (kg) |

|

JKL2 |

20 |

30 |

150 |

φ13 |

Y180L-6 |

15 |

1370×1650×1210 |

1200 |

|

JKL3 |

30 |

30 |

200 |

φ15 |

Y200L-6 |

22 |

1690×1740×1200 |

1800 |

|

JKL5 |

50 |

30 |

250 |

φ21 |

Y225S-6 |

37 |

2300×2100×1650 |

3000 |

|

JKL6 |

60 |

36 |

250 |

φ24 |

Y280S-6 |

45 |

2350×2100×1650 |

3200 |

|

JKL8 |

80 |

29 |

250 |

φ26 |

Y280M-6 |

55 |

2440×2500×1800 |

5500 |

|

JKL10 |

100 |

29 |

250 |

φ28 |

Y315S-6 |

75 |

2590×2540×1800 |

5800 |

We can design and manufacture non-standard products of various specifications according to user needs. The above parameters are subject to technical improvement without prior notice.

JK-D Inline Winch

The JK-D series uses a small-tooth-difference planetary transmission,representing the next generation of traditional winches.It offers a compact structure, smooth operation, easy handling,simple maintenance, low noise, and long service life.Widely applied in construction, docks, bridges, and metallurgy for lifting and installation tasks.It complies with GB/T10055-1996 construction hoist safety rules and JGJ88-92 industry safety standards.

Working Principle:The drum is arranged in a single-axis inline layout for high compactness.An electric motor drives the drum directly through a coupling or short-shaft reducer.The simplified electric control system supports lightweight design.

JK-D straight winch technical parameters

|

Basic date Type |

Rated load (KN) |

Rope diameter |

Rated speed |

Rated power |

Rope capacity (m) |

Overall dimension (mm) |

Weight |

|

JK0.75D |

7.5 |

φ9.3 |

30 |

3 |

100 |

900×340×400 |

165 |

|

JK1.25D |

12.5 |

φ11 |

46 |

7.5 |

120 |

1140×400×450 |

315 |

|

JK1.60D |

16 |

φ12.5 |

28 |

7.5 |

160 |

1200×440×480 |

350 |

|

JK2.0D |

20 |

φ13 |

36 |

13 |

190 |

1400×470×548 |

510 |

Note: The rated pulling force of JK0.75D and JK1.25D winches is the allowable pulling force of double ropes.

We can design and manufacture non-standard products of various specifications according to user needs. The above parameters are subject to technical improvement without prior notice.

JMM Friction-Type Winch

Designed for long-distance pulling of steel cables and lifting of large or extra-large concrete and steel structures.It provides constant rope speed and smooth hoisting.Ideal for bridge, port, dock construction,and installation of heavy factory or power-engineering equipment.

Working Principle:Uses a friction wheel instead of a gear reducer.The motor drives the friction wheel, which turns the drum through clamping force.Adjustable friction allows controlled torque and slips under overload to protect the mechanism.

JMM friction winch technical parameter table

|

Basic date Type |

Rated load (KN) |

Rated speed |

Rope capacity (m) |

Rope diameter |

Electromotor type |

Electromotor power |

Overall dimension (mm) |

Weight (kg) |

|

JMM10 |

100 |

10 |

4800 |

φ30 |

YZR225M-6 |

30 |

1980×2650×850 |

6000 |

|

JMM16 |

160 |

11 |

1000 |

φ34.5 |

YZR225M₂-6 |

45 |

3350×1920×1320 |

9500 |

|

JMM20 |

200 |

11 |

3600 |

φ39 |

YZR280S-6 |

55 |

3500×1960×1320 |

10000 |

|

JMM32 |

320 |

10 |

3200 |

φ52 |

YZR280M-6 |

75 |

4330×2350×1760 |

16000 |

|

JMM55 |

550 |

5 |

2000 |

φ60 |

YZR280M-6 |

75 |

5000×2800×1900 |

22000 |

We can design and manufacture non-standard products of various specifications according to user needs. The above parameters are subject to technical improvement without prior notice.

Although the winches above meet most standard requirements,special working conditions may exceed their limits.In such cases, customized non-standard winches provide clear advantages.A non-standard winch is designed specifically to user needs,allowing flexible parameter adjustments for the application.This ensures efficient and safe operation under unique site conditions.

Typical Application Areas of Winches

Construction Engineering

- Tower Crane: Vertical transport of materials for high-rise buildings.

- Construction Hoist: Moves personnel and materials with scaffolding systems.

- Pile Driver: Lifts heavy hammers for foundation piling.

Mining and Metallurgy

- Mine Hoist: Transports ore, personnel, and equipment underground.

- Metallurgical Crane: Handles molten steel ladles, rollers, and other heavy loads in steel plants.

Ports and Ships

- Anchor Winch: For anchoring, mooring, and cable handling on vessels.

- Port Crane: Works with lifting gear for container and bulk cargo loading and unloading.

Water Conservancy and Power

- Dam Gate Hoist: Raises and lowers sluice gates for water control.

- Cable Laying Machine: Pulls and installs high-voltage power cables.

Rescue and Special Operations

- Fire Ladder Truck: Supports high-altitude rescue operations.

- Earthquake Rescue Equipment: Clears debris and moves heavy objects during disaster relief.

Common Faults and Maintenance

|

Fault Phenomenon |

Possible Cause |

Solution |

|

Wire rope jumps groove |

Pulley misalignment or wear |

Align pulley, replace worn parts |

|

Brake failure |

Worn brake pads or hydraulic leak |

Replace friction pads, inspect hydraulic system |

|

Abnormal noise |

Damaged bearing or worn gears |

Lubricate or replace defective components |

|

Motor overheating |

Overload or poor ventilation |

Check load, improve cooling or airflow |

Winches are core equipment for lifting and pulling, and their performance directly affects engineering safety and efficiency.HSCRANE Heavy Industry, with strong technical expertise and extensive field experience, offers both standardized and custom winches to meet diverse working conditions. We emphasize scientific selection, proper operation, and intelligent maintenance to ensure long-term stable performance.

As industrial automation advances, HSCRANE continues to innovate, driving winches toward smarter, more efficient, and safer solutions. From tunnel construction and mining to port lifting and special operations, our winches deliver exceptional performance to boost productivity and create greater value.